Control method of near-resonance vibrating screen machine

A control method and near-resonance technology, applied in chemical instruments and methods, screening, solid separation, etc., can solve the problems of small amplitude, slow screen speed, and single frequency, so as to improve the efficiency of material screening and avoid changing the amplitude , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

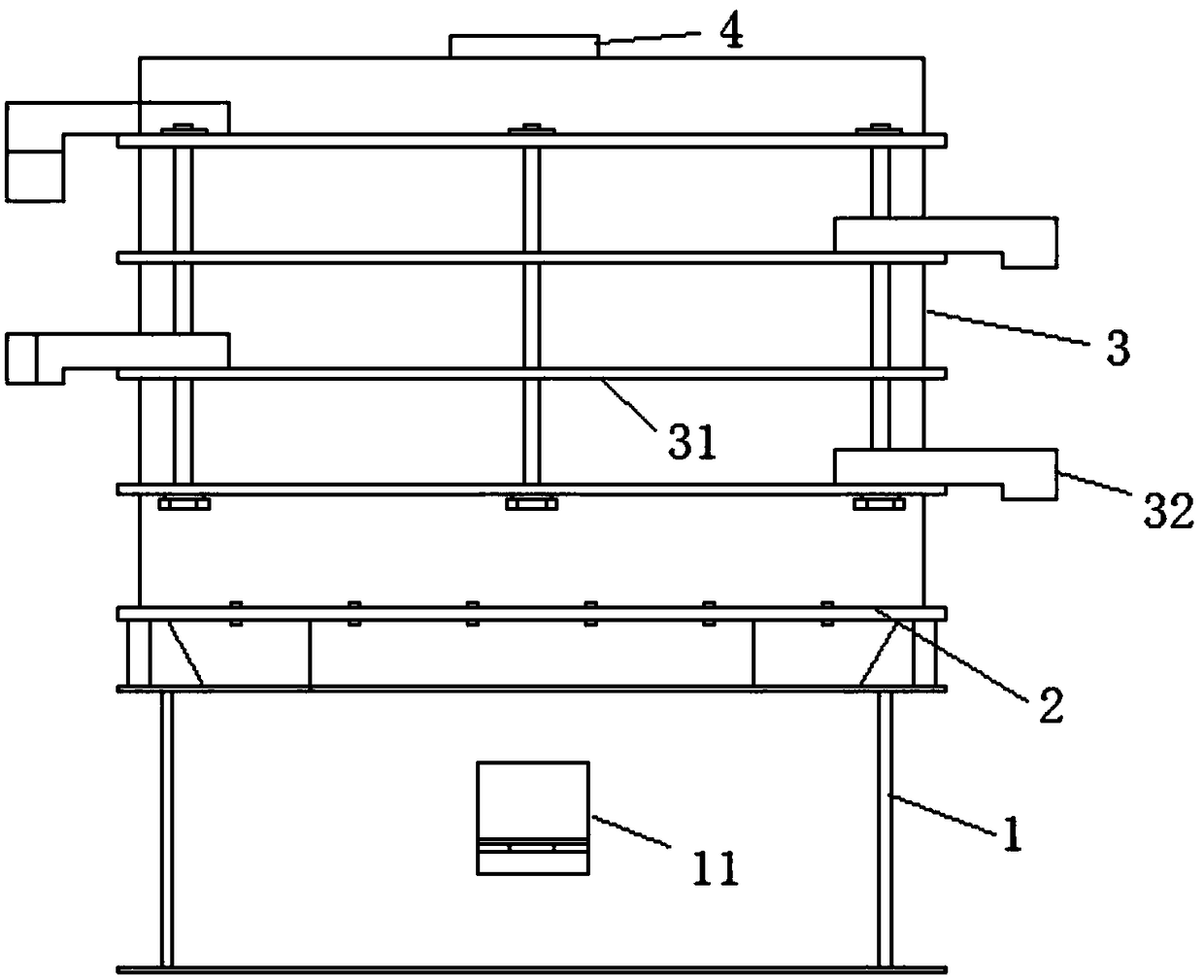

[0024] refer to figure 1 As shown, the present embodiment is a control method of a near-resonance type vibrating screen machine. The near-resonance type vibrating screen machine includes a machine base 1, and a driving device and an eccentric block (not shown in the figure) are fixed in the machine base 1. The driving device consists of A control system (not shown in the figure) controls the connection, and a sensor (not shown in the figure) is also arranged in the control system. The driving device in this embodiment is a vibrating motor 11 . A vibrating device is installed on the top of the support 1, and the vibrating device in this embodiment is a spring vibration isolator 2. The near-resonance vibrating screen machine also includes a screen grid 3 installed on the vibrating device. The screen grid 3 is provided with a screen 31. The screen grid 3 has four layers. The gaps of the screens 31 of each layer are different. Make a distinction. A discharge opening 32 is provi...

Embodiment 2

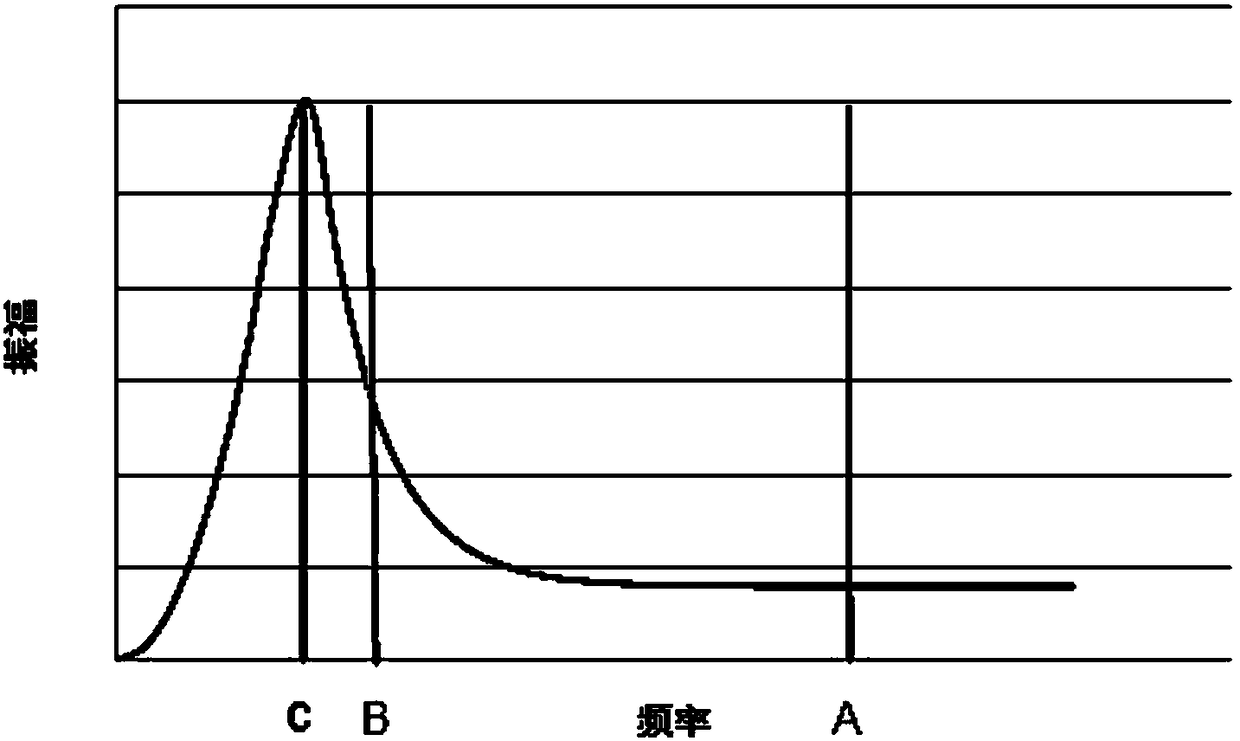

[0027] refer to Figure 1-2 As shown, the control method of the near-resonance vibrating screen machine, the first step: the vibration motor 11 and the screen 31 are separated from the base 1 by the spring isolator 2, and the vibration motor 11 and the screen 31 respectively form an independent vibration system; the second The second step: the control system is turned on, and the vibration motor 11 rotates to drive the eccentric block to vibrate the screen 31; the third step: the screen 31 starts to vibrate, and approaches the operating frequency A of the vibration motor 11 after passing through the resonance point C; the fourth step : After the screen 31 vibrates to the operating frequency A, the material behavior enters a steady state. At this time, the control system starts counting until the set time, the control system cuts off the operating signal for controlling the vibration motor 11, and the screen 31 begins to approach the resonance point C. The amplitude increases, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com