Screening device beneficial for improving efficiency

A screening device and efficiency technology, applied in the field of machinery, can solve problems such as low screening efficiency, and achieve the effect of improving screening efficiency and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

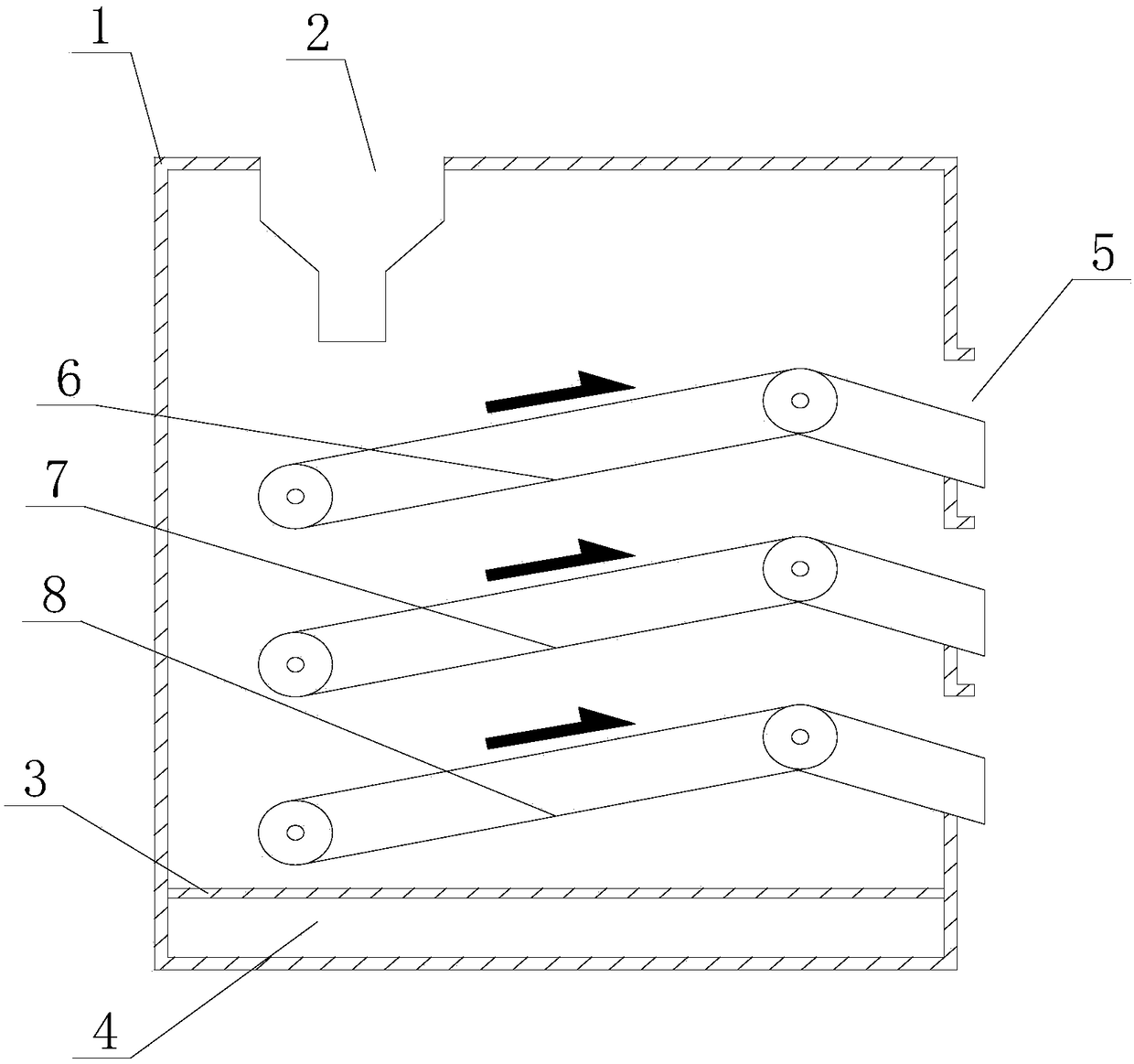

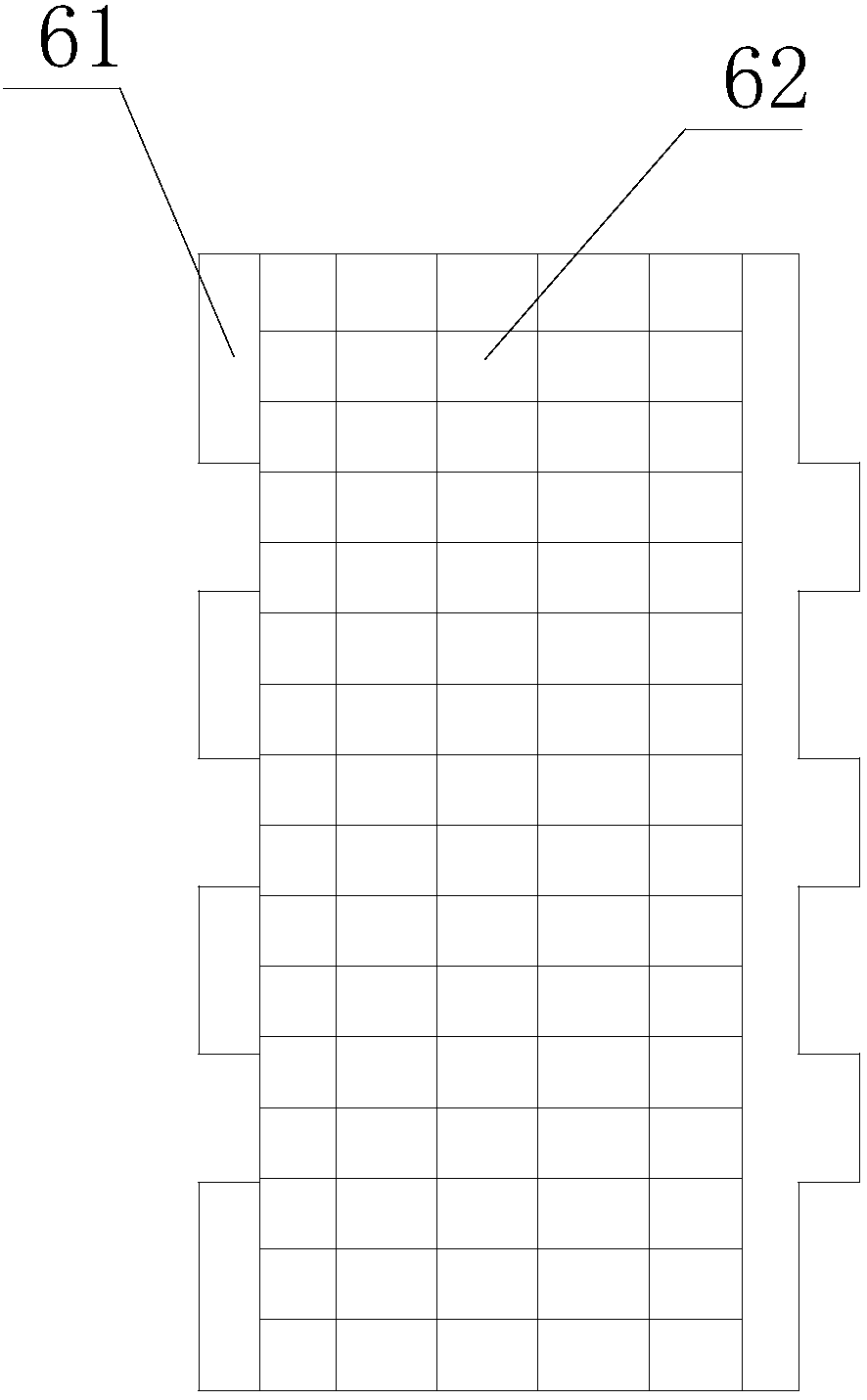

[0021] like figure 1 and figure 2 As shown, the present invention is conducive to the screening device of improving efficiency, comprises body 1, feed inlet 2, partition 3, conveyor belt and discharge port 5; Divided into a sieve room and a waste room 4; the conveyor belt is arranged in the sieve room, and the downstream height of the conveyor belt is higher than the downstream height; the feed inlet 2 is arranged on the upper top of the body 1, and the feed inlet 2 faces Conveyor belt; the discharge port 5 is arranged on the side wall of the body 1, and the discharge port 5 is connected to the downstream end of the conveyor belt; when the conveyor belt is running, the aggregate on the conveyor belt is discharged from the discharge port 5; the conveyor belt adopts A crawler conveyor belt, and the conveyor belt includes a track shoe 61 and a screen 62; the screen 62 is arranged on the track shoe 61 and runs through the track shoe 61; the number of the conveyor belts is two or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com