A kind of rba leaf spring assembly and its automobile

A technology of leaf springs and assemblies, applied in the direction of springs, spring assemblies composed of several springs, vehicle springs, etc., can solve problems such as breakage at the contact of RBA leaf springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

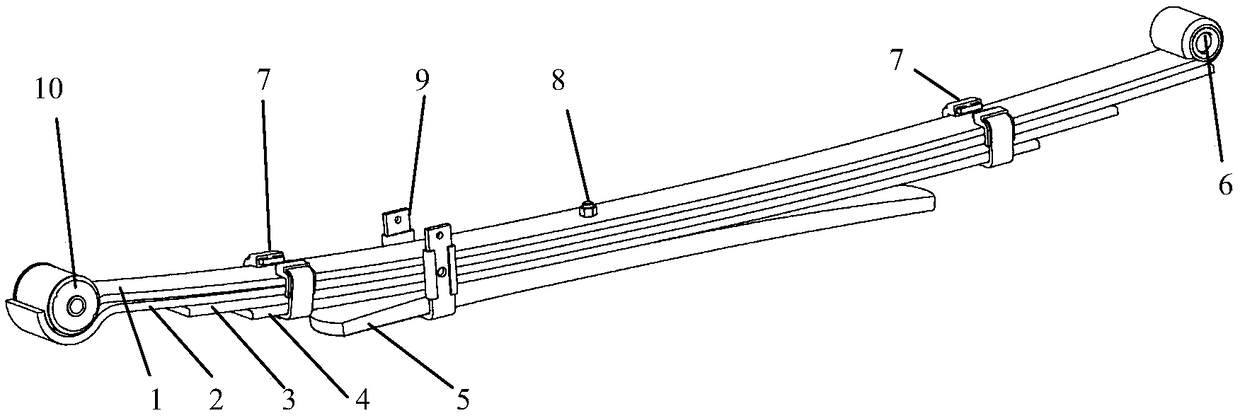

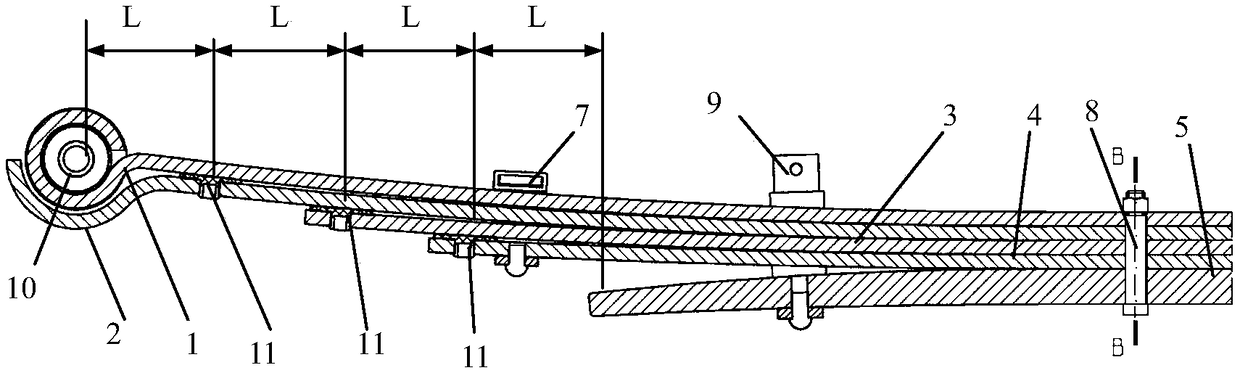

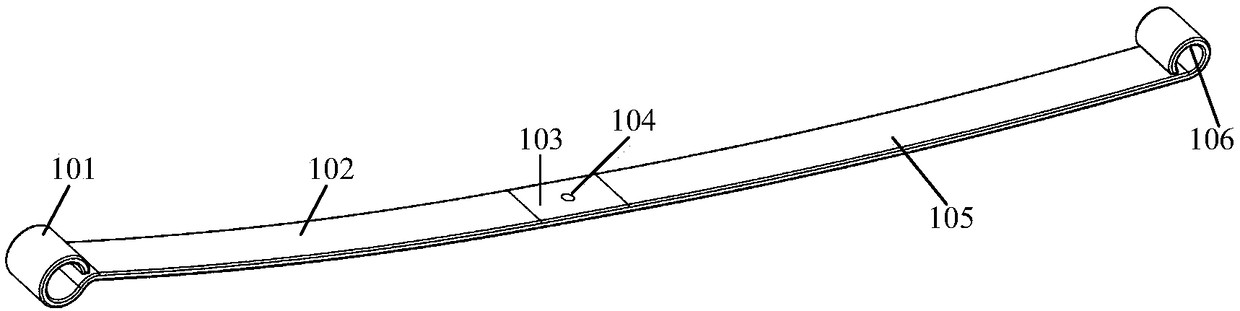

[0051] The main spring of the current RBA leaf spring for automobiles is usually composed of two leaf springs with the same cross-section and equal effective length. Because the stress of the leaf spring is small at both ends and the middle is large, the stress is uneven. When the load is large, the main spring is flattened or even When bowing, the stress of the main spring at the end of the auxiliary spring is too large, and fatigue fracture is caused. The present invention provides an RBA leaf spring assembly. The main spring is composed of 4 equal-section leaf springs whose length gradually shortens from top to bottom, and has an upward circular arc structure. The auxiliary spring adopts a single-piece variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com