Carbon-free cycling forklift

A riding and forklift technology, which is applied in the field of carbon-free riding forklifts, can solve the problems of pollution, short transportation distance, labor-intensive, and high operating requirements for drivers, and achieve flexible and convenient operation, good market promotion and application value, and simple structural design Sophisticated Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

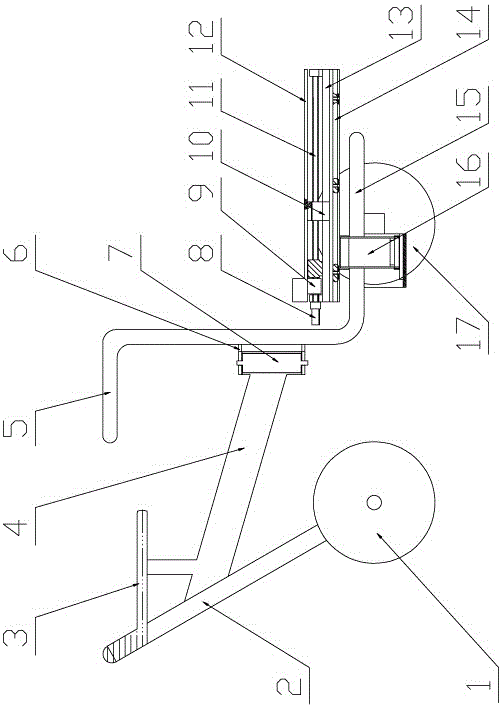

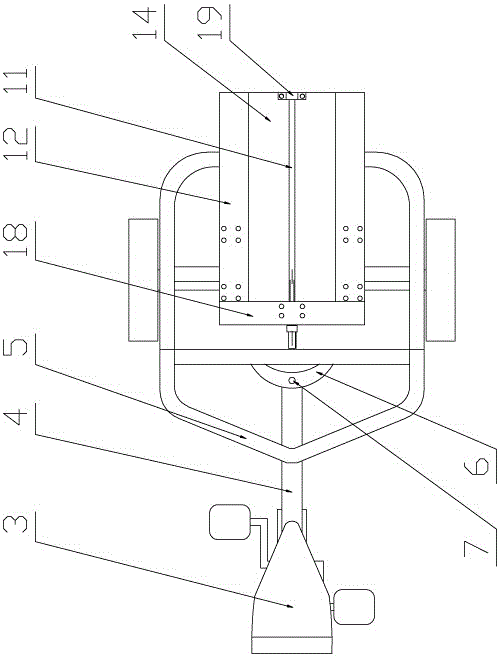

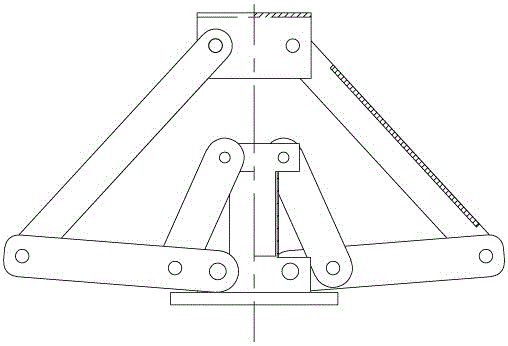

[0016] see Figure 1-Figure 3 , the present invention is a carbon-free riding forklift, which has a frame 15, a running wheel 17 is arranged at the bottom of the frame, and a riding driving device is arranged at the rear of the frame, and the driving device and the frame are connected by a rotating shaft. 7 is rotatably connected with the rotating seat 6; the upper part of the frame is provided with a steering handle 5, and the middle part of the frame is provided with a manual hydraulic jacking device 16, and a seat plate 14 is provided at the ejection end of the manual hydraulic jacking device, and a seat plate 14 is provided on the seat plate. With manual fork hand mechanism.

[0017] The riding driving device described in this embodiment has a riding frame 2, a pedal wheel 1 is installed at the bottom of the riding frame, a seat 3 is arranged on the riding frame, and a connecting rod 4 is arranged horizontally in the middle of the riding frame to connect One end of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com