Multi-station multi-extended-station stacker, three-dimensional storage goods shelf and three-dimensional storage warehouse

A stacker, multi-station technology, applied in the direction of the lifting device, etc., can solve the problems that the stacker cannot store the goods well, the goods cannot be taken out, and the size of the goods is special.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, a multi-station and multi-extension stacker, a three-dimensional storage shelf and a three-dimensional storage warehouse provided by the invention will be described below in conjunction with the drawings and specific embodiments. described in further detail.

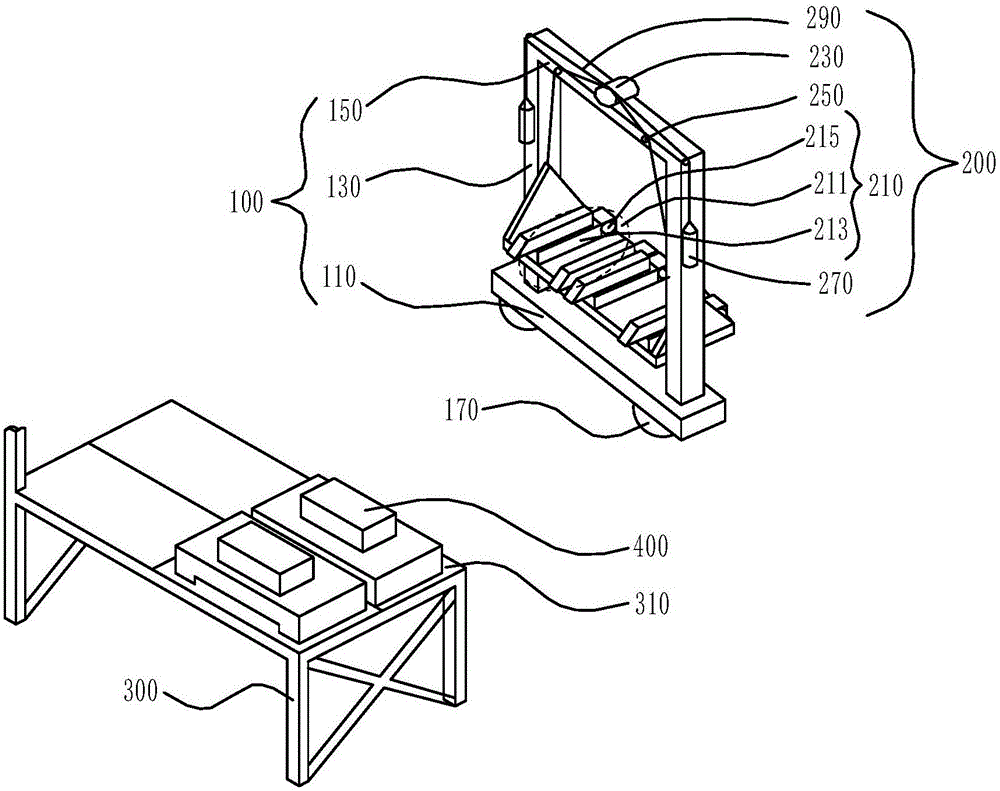

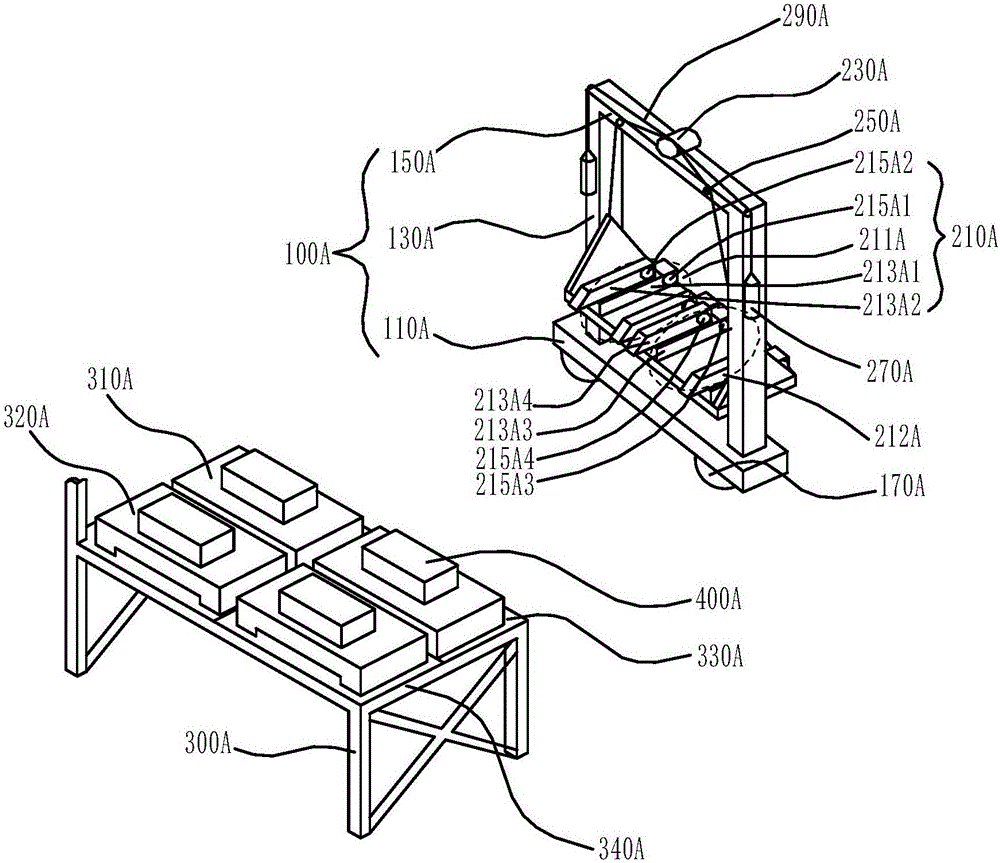

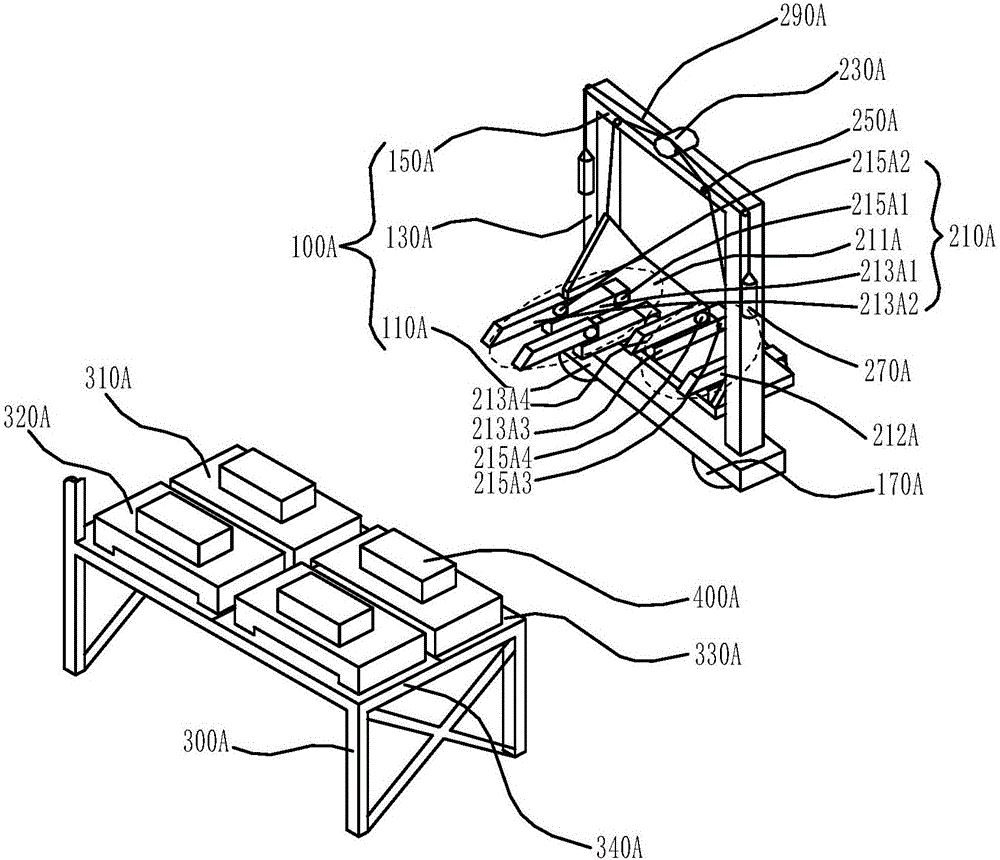

[0029] see figure 1 , figure 1 It is a structural schematic diagram of the first embodiment of the multi-station and multi-extension stacker of the present invention. The multi-station and multi-extension stacker includes: a main frame 100 and a lifting mechanism 200 installed on the main frame 100; the main frame 100 includes a base 110, two columns 130 installed on the base 110, and The beam 150; the lifting mechanism 200 includes a loading platform 210 and a traction machine 230 connected to and lifting the loading platform 210, the loading platform 210 moves up and down along the column 130, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com