Wire take-up device for non-binding steel stranded wire

A wire take-up device and a technology for steel strands, which are applied in rope-making auxiliary devices, textiles and papermaking, textile cables, etc., can solve problems such as affecting steel strands, damage, and failure to remove steel strand coils smoothly, and achieve The effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

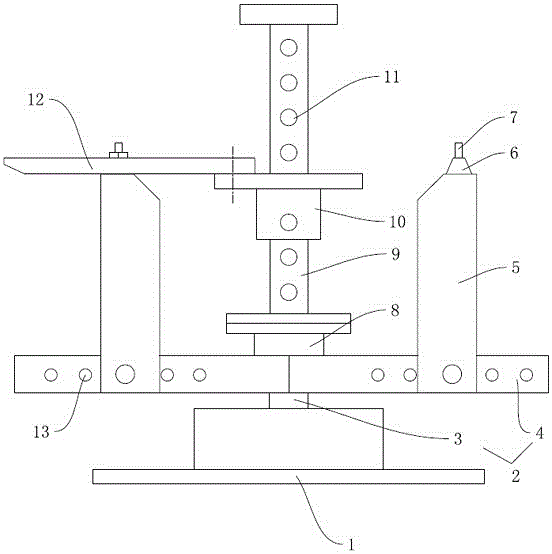

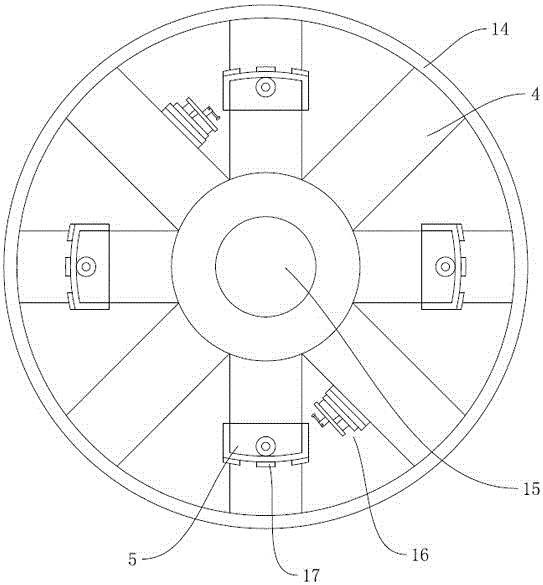

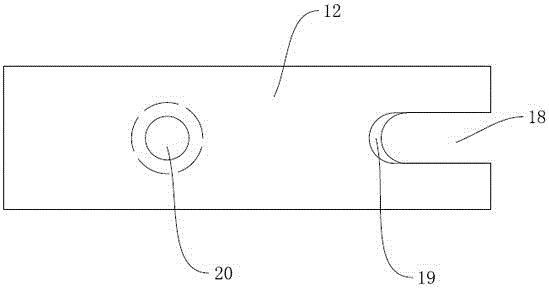

[0023] Embodiment: a kind of unbonded steel strand take-up device (referring to figure 1 figure 2 ), including a base 1 and a rotatable turntable 2 arranged on the base, the turntable includes a rotating shaft 3 and a support arm 4 radially fixed on the rotating shaft, and the outer ends of the supporting arms are connected by an outer ring 14 . In this embodiment, a total of 8 support arms are radially arranged, the lengths of the support arms are equal, the outer ring forms a circle, the cross section of the support arms is rectangular, and the upper surface of the support arms is fixed with pads. The support arm is provided with several radial adjustment holes 13 horizontally penetrating the side wall of the support arm, and the radial adjustment holes are arranged on the support arm along the length direction of the support arm.

[0024] The base is provided with a driving motor, the rotating shaft is connected with the driving motor, the driving motor drives the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com