Automatic garbage bag hot-sealing device and method of garbage can

A technology for garbage bags and garbage cans, applied in the field of automatic heat-sealing garbage bag devices for garbage cans, can solve the problems of complex devices, inaccurate, cumbersome control, etc., and achieve the effects of reducing direct contact, accurate and efficient packaging, and saving human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

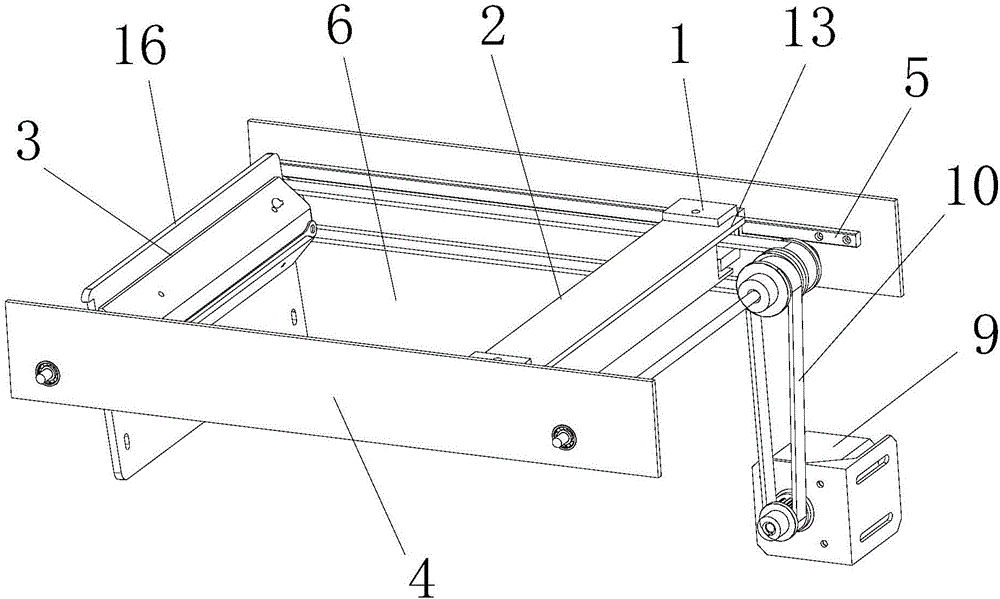

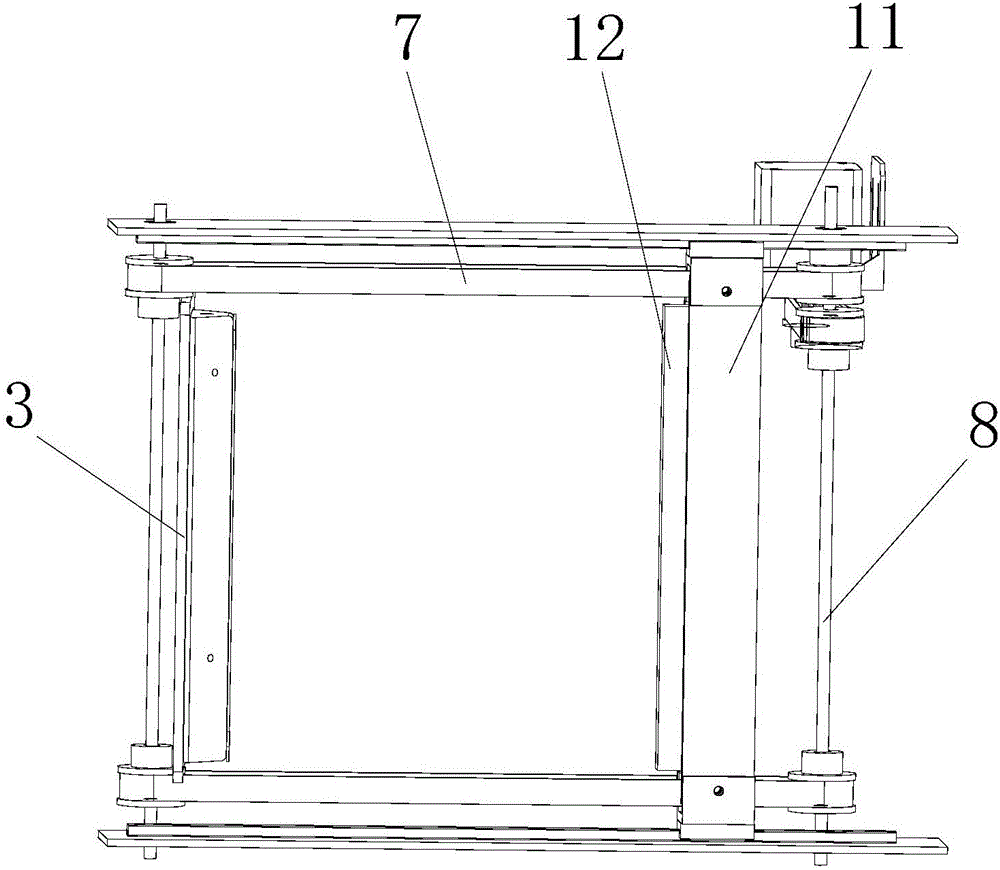

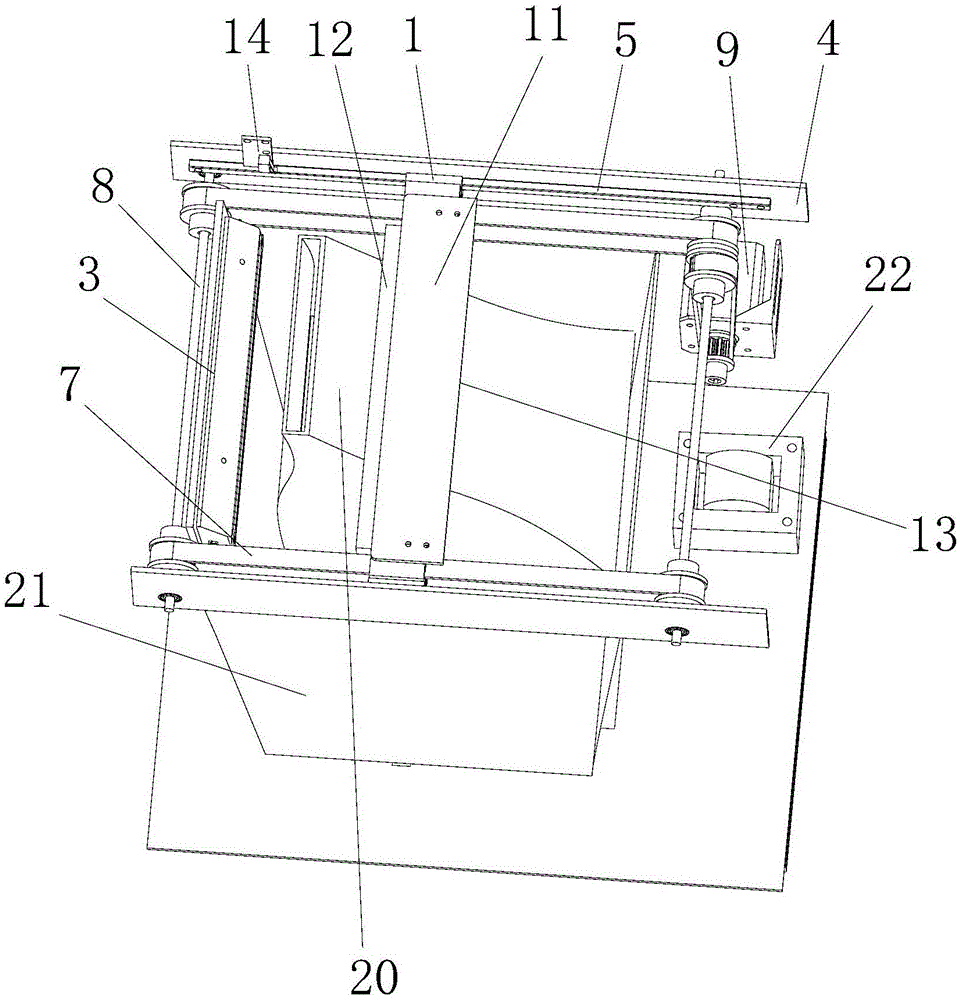

[0024] An automatic heat-sealing garbage bag device for a garbage can, comprising a slider 1, a clamping plate 2, a heating module 3, a driving mechanism for driving the clamping plate to move to the heating module, and a frame 4 arranged on the mouth of the garbage can 21 , the heating module is fixed on the frame, there are guide rails 5 on both sides of the frame, there are two sliders, which are respectively matched with the guide rails on both sides of the frame, the clamping plate is installed on the two sliders, and the clamping plate and A pocket placement area 6 is formed between the heating modules, and the pocket placement area is located on the mouth of the trash can.

[0025] The slider cooperates with the guide rail to slide to achieve the effect of reducing friction.

[0026] Preferably, the drive mechanism includes a power mechanism, a synchronous pulley set and a synchronous belt 7, the synchronous pulley set includes two synchronous pulleys, and the two synch...

Embodiment 2

[0038] A method for automatically heat-sealing garbage bags in garbage cans. When sealing the garbage bags, the driving mechanism starts, and the clamping plate moves to the heating module under the push of the driving mechanism. During the movement, the clamping plate pushes the garbage bag One side of the opening moves closer to the other side. When the clamping plate contacts the heating module, the opening of the garbage bag is closed. At this time, the heating module is activated to melt the opening of the garbage bag and seal the opening of the garbage bag. , Then, the driving mechanism is started, and the clamping plate is reset under the traction of the driving mechanism, and the sealed garbage bag can be taken out at this time.

[0039] Preferably, when the clamping plate is in contact with the heating module, the clamping plate is in contact with the touch switch, the touch switch is triggered, a touch signal is sent to the controller, and when the controller receives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com