Novel online oven for steel wires

An oven, steel wire technology, applied in drying, dryer, progressive dryer and other directions, can solve the problems of high energy consumption, easy to produce staggered knots, low work efficiency, etc., to achieve high drying efficiency and reduce energy consumption , the effect of short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

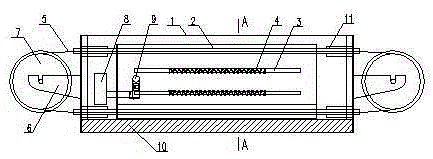

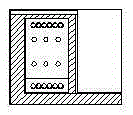

[0015] A new type of steel wire online oven, comprising an oven 1, a row of horizontally arranged heat transfer tubes 2 are respectively arranged at the upper and lower ends of the oven 1, the two ends of the heat transfer tubes 2 run through the two ends of the oven 1, and the two rows of heat transfer tubes Two rows of electric heating pipes 3 are arranged between the heat pipes 2, the electric heating pipes 3 are covered with electric heating wires 4, the steel wires 5 to be dried are worn inside the heat transfer pipes 2, and the two ends of the oven 1 are provided with support seats 6, A wire passing wheel 7 is placed on the support base 6, and the two ends of the steel wire 5 are sleeved on the wire passing wheel 7. A fan 8 is installed at the front end of the oven 1, and the fan 8 is connected to the front end surface of the oven 1. The air inlet 9 is connected; the tube wall of the heat transfer pipe 2 is provided with a number of heat inlet holes; the air inlet 9 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com