Intraocular lens injector control system

A technology for intraocular lenses and syringes, which can be used in subcutaneous injection devices, intraocular lenses, prostheses, etc., and can solve problems such as annoying surgical preparation steps and failure to ensure good airtightness of the hydraulic transmission system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

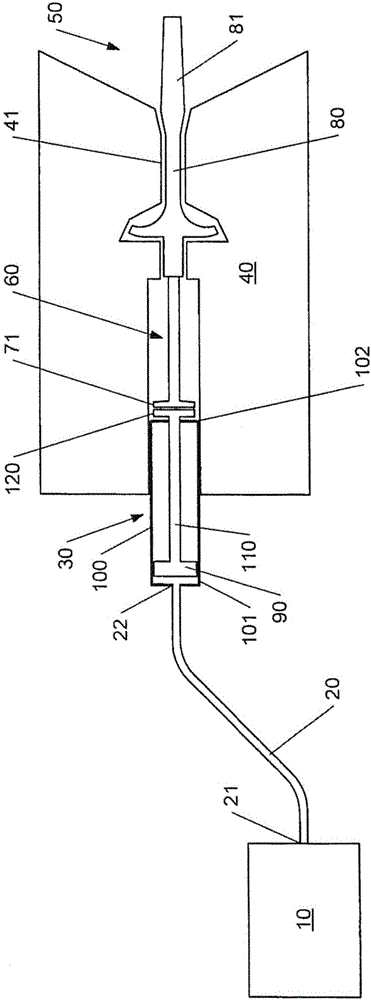

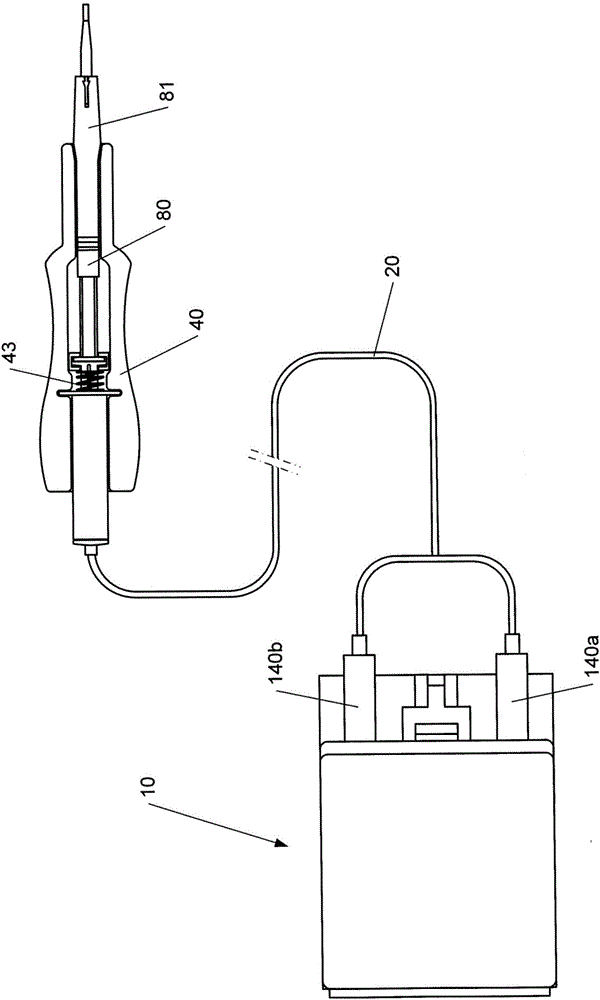

[0088] In this figure, identical or similar elements have the same reference numerals.

[0089] figure 1 A control device 1 for an intraocular lens injector 50 according to the invention is schematically shown.

[0090] Device 1 includes:

[0091] - a control module 10, which may for example be a control pedal;

[0092] - a support 40 arranged to accommodate an intraocular lens injector 50;

[0093] - the actuator 30 of the support 40, which is connected to the control module 10 by means of an airtight fluid transfer system 20, which actuator is arranged to communicate with an injector which may be an actuating device such as a moving piston system housed in a cylinder Part of 50 fits.

[0094] Optionally, the delivery system comprises several parts arranged to be interconnected and thereby form an airtight fluid hydraulic delivery system.

[0095] figure 2 is a schematic illustration of a variant of the control device 1 according to the invention, wherein the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com