Brake system having a blending capability

A technology of braking equipment and braking circuit, applied in the direction of braking control system, braking safety system, braking transmission device, etc., can solve problems such as reducing braking power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

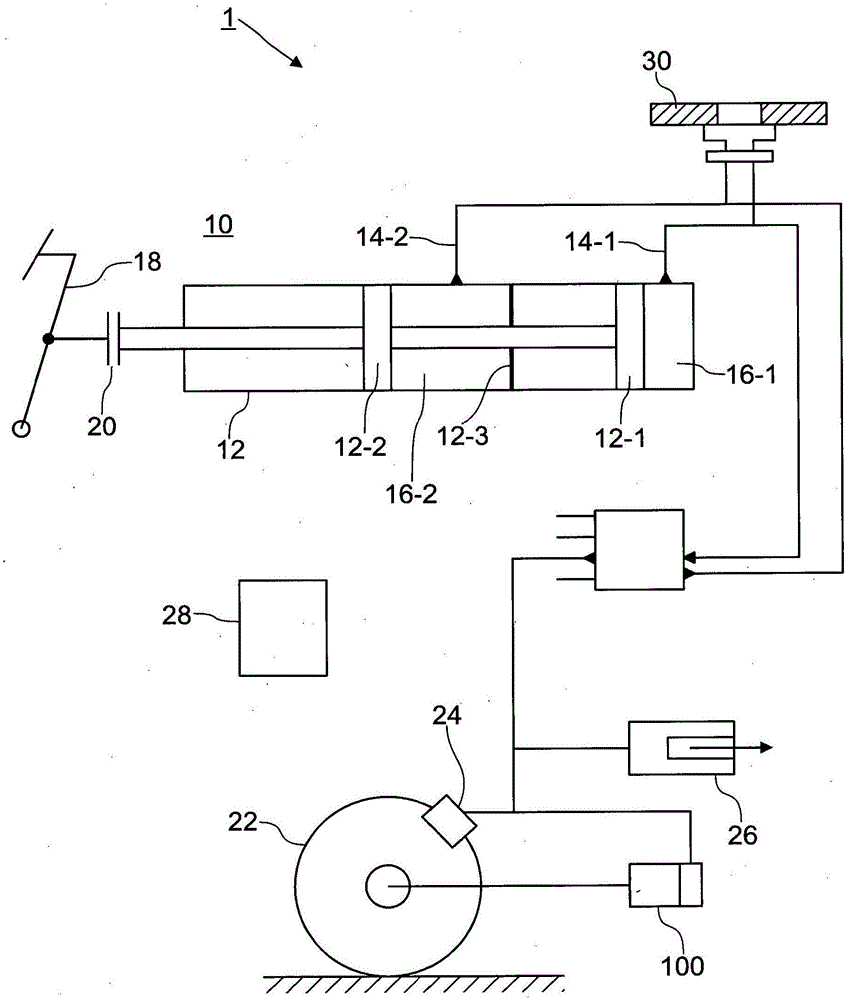

[0023] figure 1 A braking system for a motor vehicle is shown, which is generally designated with reference number 1 .

[0024] The brake system 1 has a hydraulic brake, generally designated by the reference number 10 , and an electric machine 100 , which can be used as a regenerator, for example on the rear axle of a motor vehicle.

[0025] The total braking power generated by the brake system 1 therefore includes the mechanical braking power of the hydraulic brake 10 and the regenerative torque of the electric machine 100 in the event of a braking request from the driver.

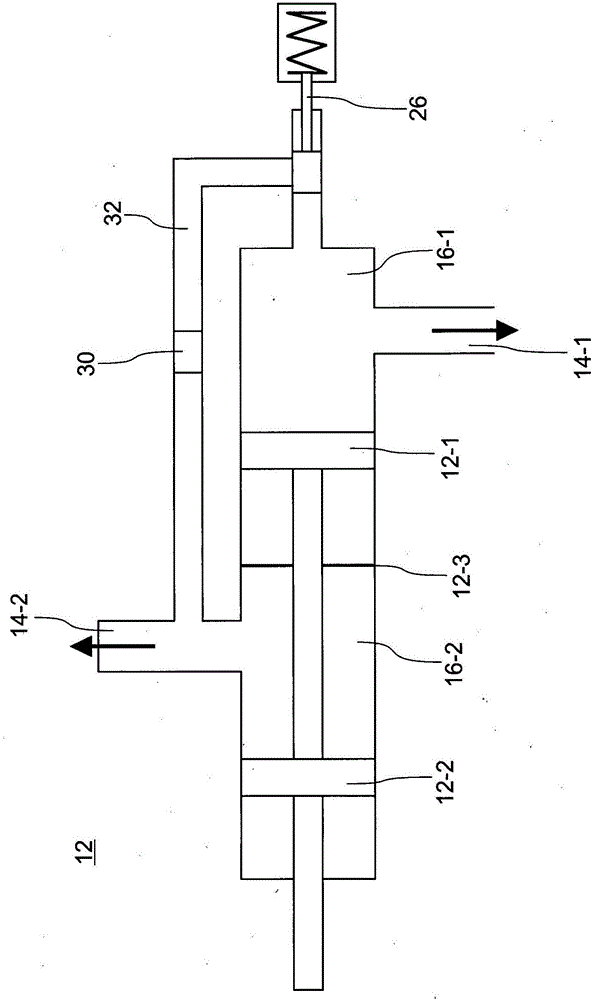

[0026] The hydraulic brake 10 includes a brake master cylinder 12, the first brake piston 12-1 of which supplies hydraulic brake pressure to the first brake circuit 14-1, and the second brake piston 12-2 of which supplies hydraulic brake pressure to the first brake circuit 14-1. A second brake circuit 14-2 separate from circuit 14-1 supplies hydraulic brake pressure.

[0027] For example from figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com