Braking system for operating mechanism of crane and control method of braking system

A technology of operating mechanism and braking system, applied in the directions of transportation and packaging, hoisting device, load hanging element, etc., can solve the problems of inconvenient operation, causing accidents, non-compliance, etc., so as to improve safety, reliability and reliability. Braking ability, avoid the effect of excessive braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

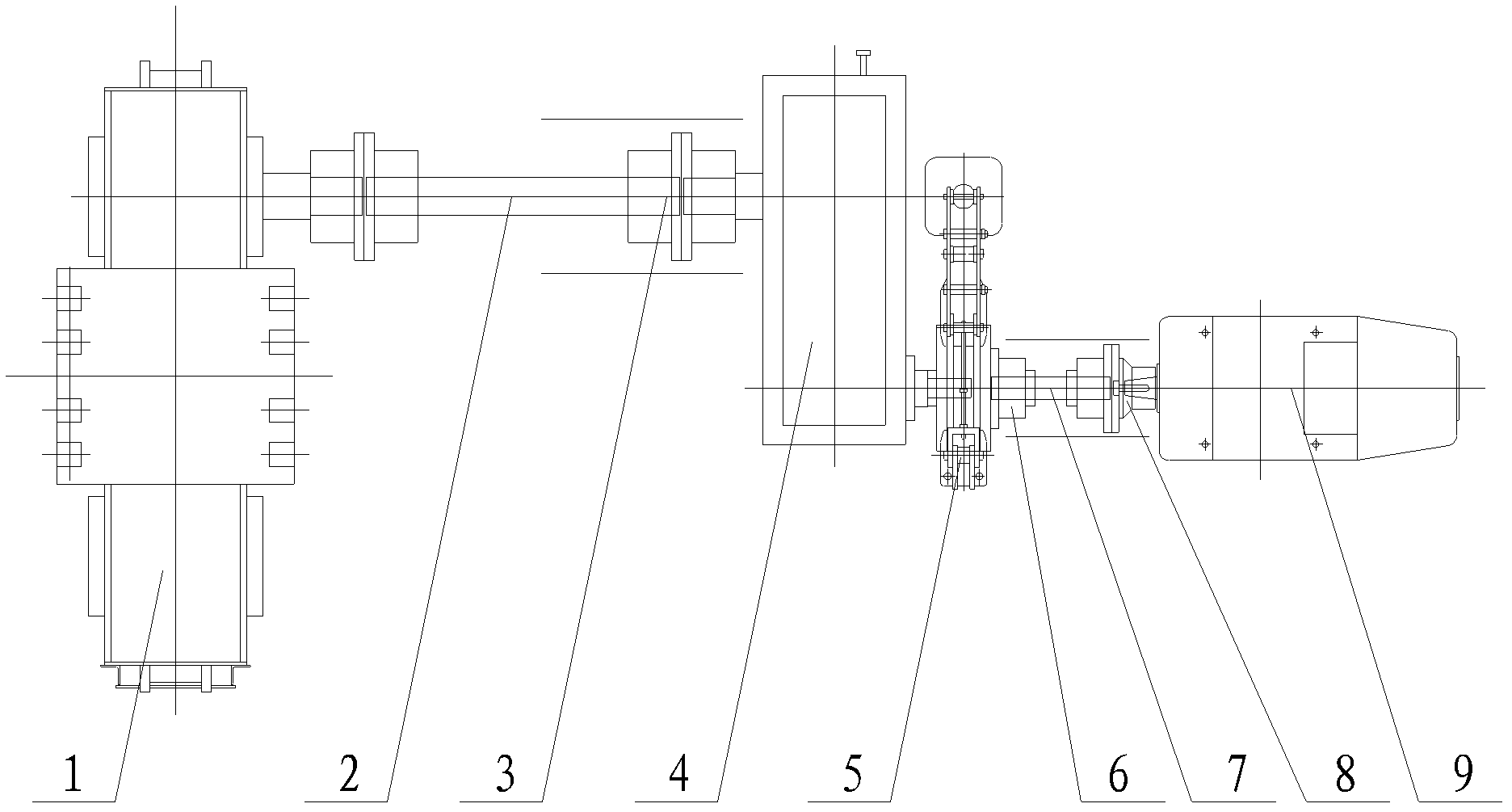

[0031] Embodiment 1 is an embodiment in which the working brake 11 and the safety brake 12 are arranged on the floating shaft 7 between the reducer 4 and the motor 9, wherein the working brake 11 is arranged near the end of the reducer 4, and the safety brake 12 is arranged near the motor 9 one end, such as image 3 shown.

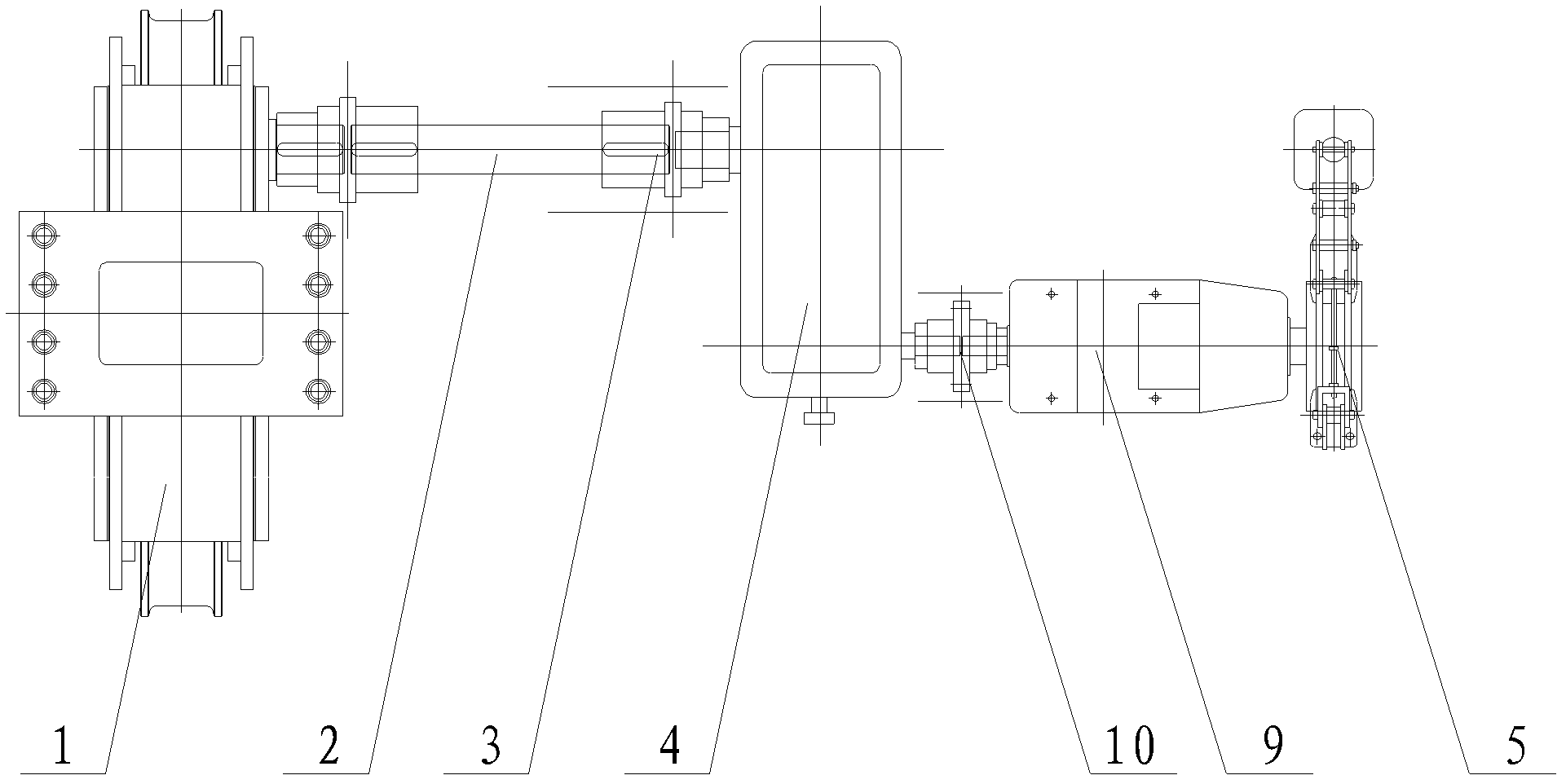

[0032] Figure 4 The arrangement form of embodiment 2 is given. In embodiment 2, the working brake 11 and the safety brake 12 are arranged on both sides of the reducer 4, wherein the working brake 11 is arranged on the input shaft on the output side of the reducer 4, and the safety brake 12 is arranged on the On the floating shaft on the input side of reducer 4. A floating shaft 7 is provided between the reducer 4 and the motor 9 .

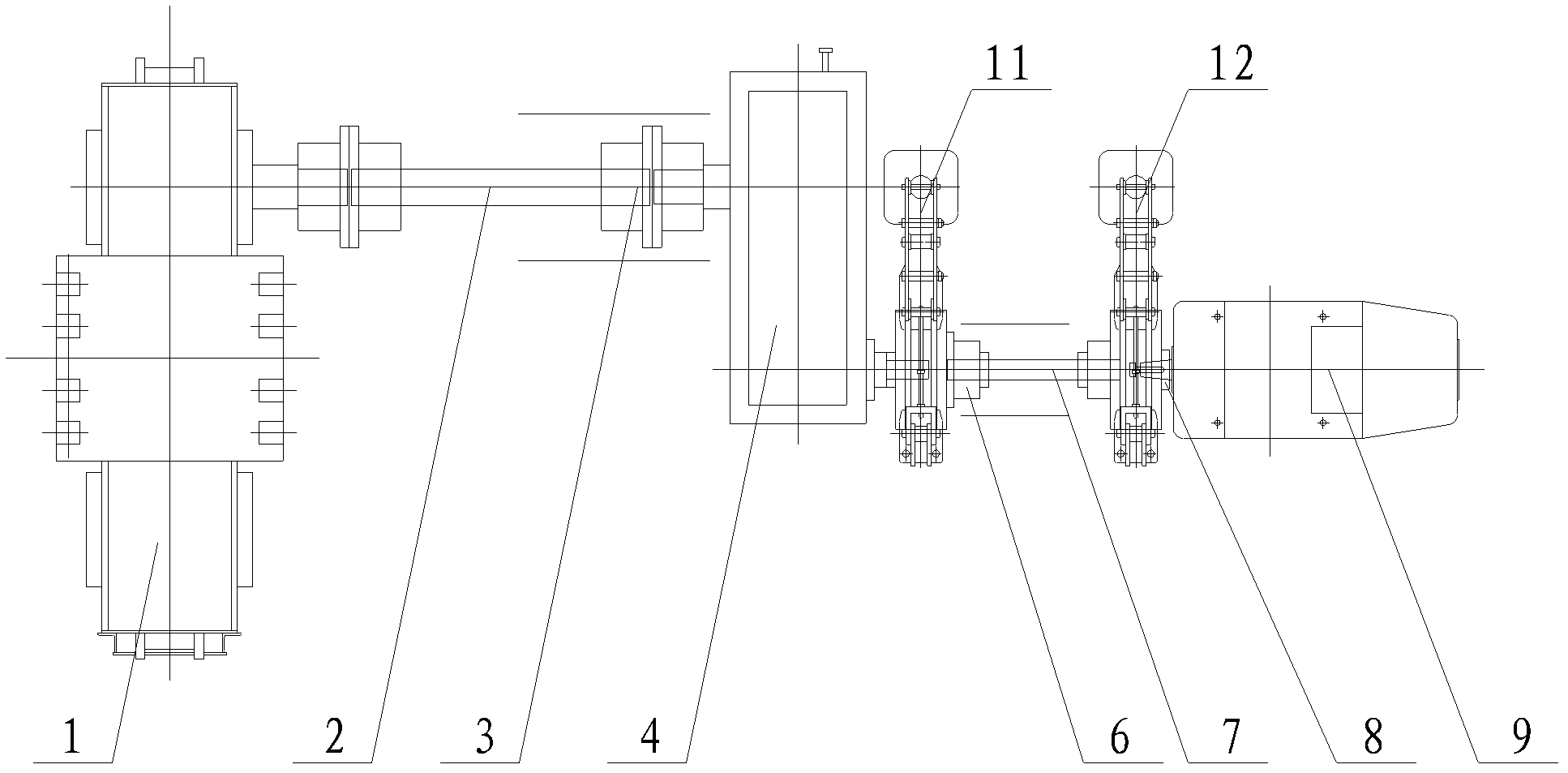

[0033] Figure 5 The arrangement form of embodiment 3 is given. In embodiment 3, the working brake 11 and the safety brake 12 are arranged on both sides of the reducer 4, wherein the working brake 11 is arranged on the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com