Unsymmetrical dimethylhydrazine decontamination apparatus and unsymmetrical dimethylhydrazine decontamination method

A technology of unsymmetrical dimethylhydrazine and decontamination, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as difficulty in decontamination, surrounding environmental pollution, and expansion of polluted areas, and achieve the degree of pollution prevention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

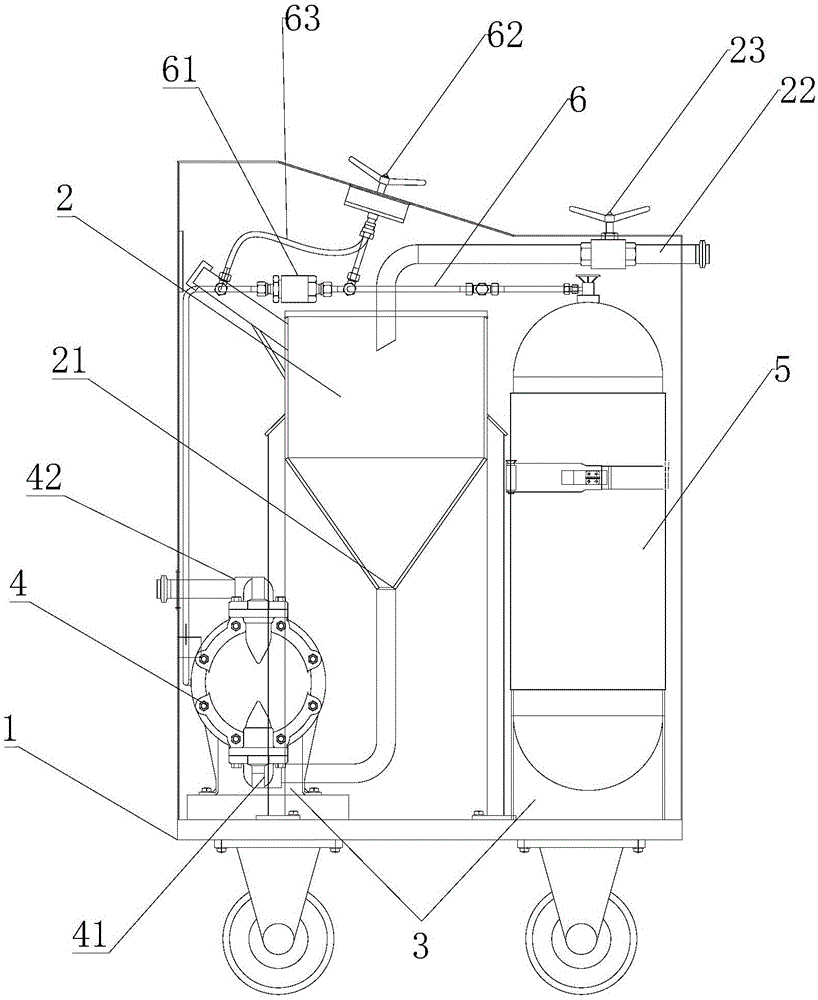

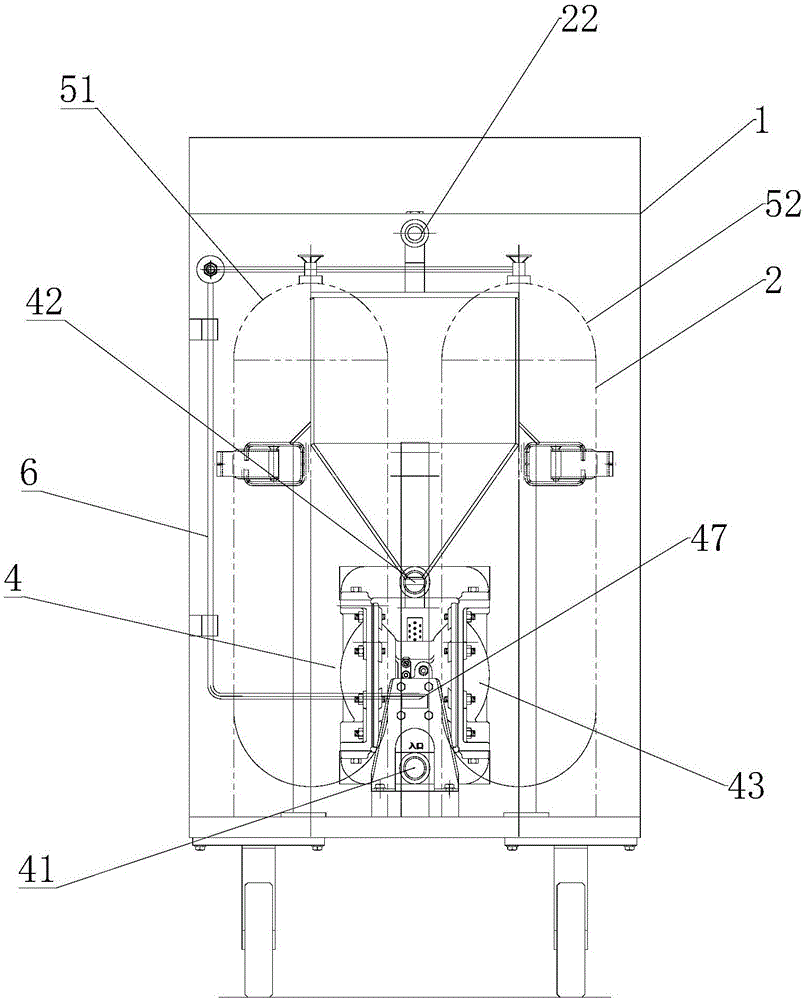

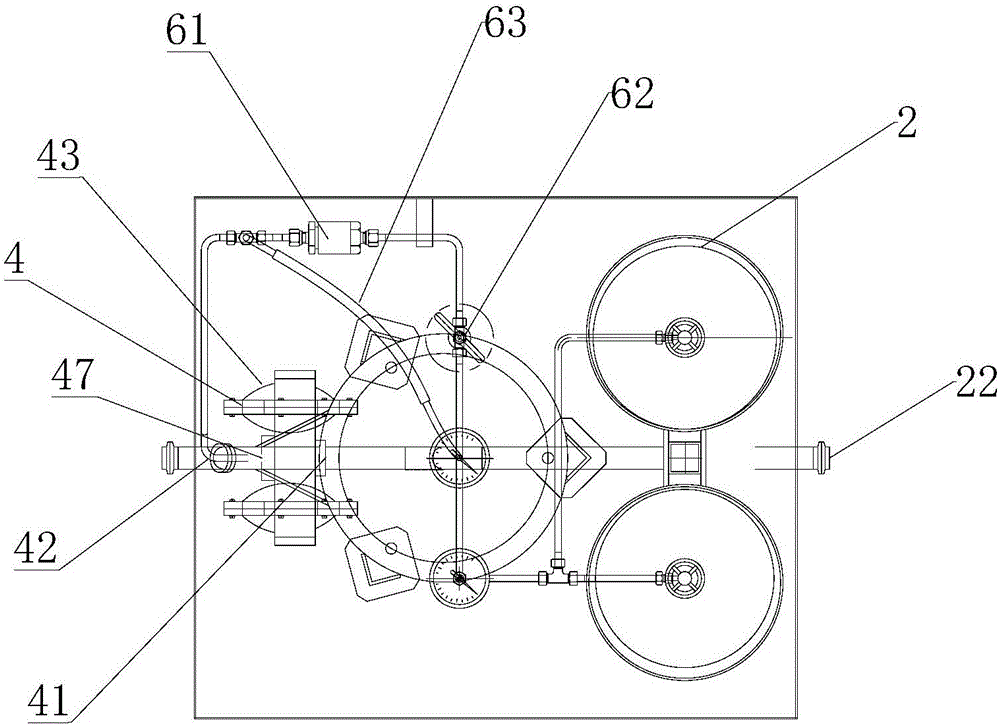

[0035] Such as figure 1 and 4 As shown, as a further preferred mode of the embodiment of the present invention, the pneumatic powder conveying device 4 has a feed port 41 and a discharge port 42. On the upper part of the outer wall 432 of the working chamber 43, the feed port 41 is connected with the powder decontamination agent storage tank 2, the feed port 41 has a negative pressure for sucking the decontamination agent under the action of high-pressure gas, and the discharge port 42 has a spray The positive pressure of the decontamination agent, the powder is sucked into the pump chamber under the action of negative pressure, and then output in a positive pressure state at the discharge port.

[0036] Such as Figure 4 As shown, preferably, the pneumatic powder conveying device 4 is a pneumatic elastic diaphragm pump. The pneumatic elastic diaphragm pump includes two symmetrical working chambers 43, and check valves are provided at the inlet 41 and the outlet 42 of the wo...

Embodiment 2

[0039] The difference between this embodiment and the above-mentioned embodiment is that the pneumatic elastic diaphragm pump is replaced by a Venturi tube structure as the pneumatic powder conveying device. The high-pressure gas enters the air inlet to generate negative pressure at the feed inlet, and the powder is sucked into the tube body, and finally the powder in the tube is discharged through the high-pressure gas to carry out the decontamination operation.

Embodiment 3

[0041] Such as figure 1 and 2 As shown, as a further preferred mode of the embodiment of the present invention, a pressure reducer 61 is installed on the gas pipeline 6 between the high-pressure gas cylinder 5 and the pneumatic powder conveying device 5, and a pressure reducer 61 is installed between the high-pressure gas cylinder 5 and the pressure reducer 61. A control valve 62 for controlling the flow of gas in the high-pressure gas cylinder 5 is provided, and the pressure of the gas delivered by the high-pressure gas cylinder 5 is reduced to the working pressure of the pneumatic powder conveying device through the pressure reducer 61, so that the output is more stable.

[0042] Such as figure 1 and 2 An air guide tube 63 is installed on the gas delivery pipeline 6 between the pressure reducer 61 and the pneumatic powder delivery device 4 , and one end of the air guide tube 63 is connected to the delivery pipeline 6 between the pressure reducer 61 and the pneumatic powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com