Time delay sampling liquid sampler and sampling method

A liquid sampling and sampling port technology, applied in the direction of sampling devices, etc., can solve the problems of sampling, inconvenient sampling, and inability to sample and analyze samples at different depths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

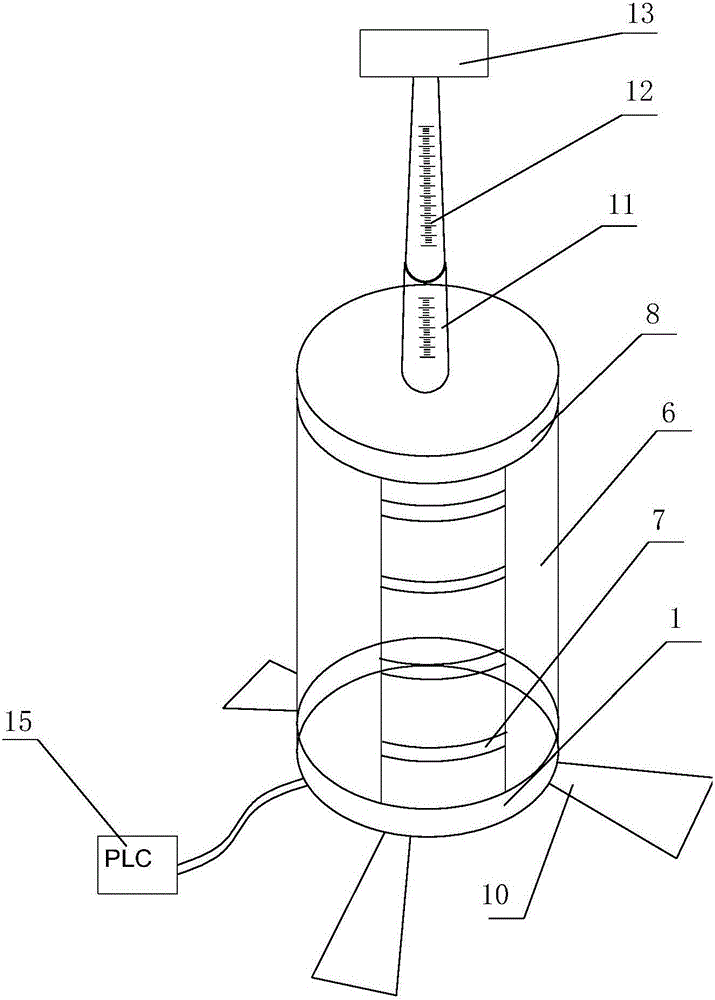

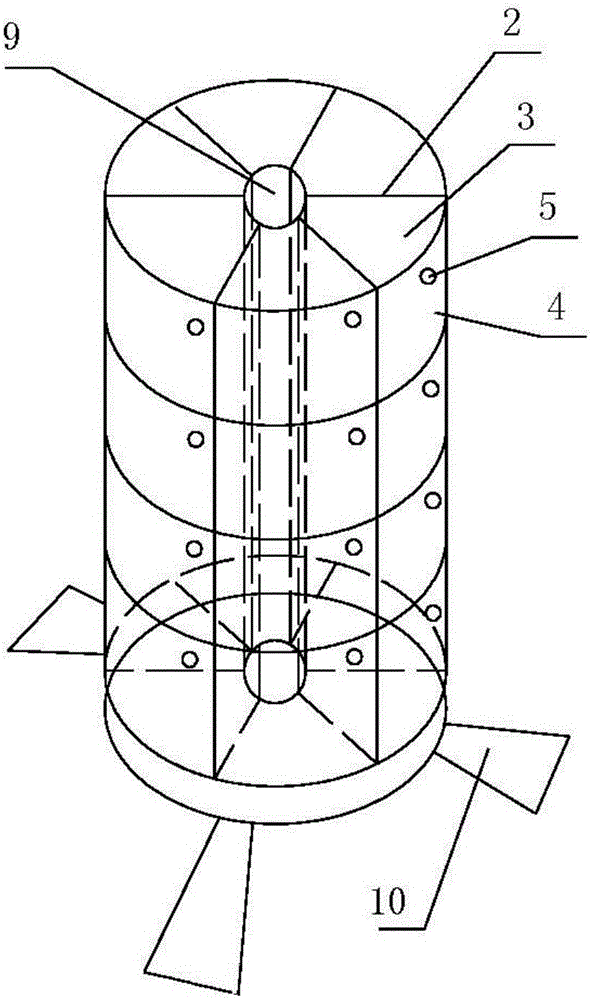

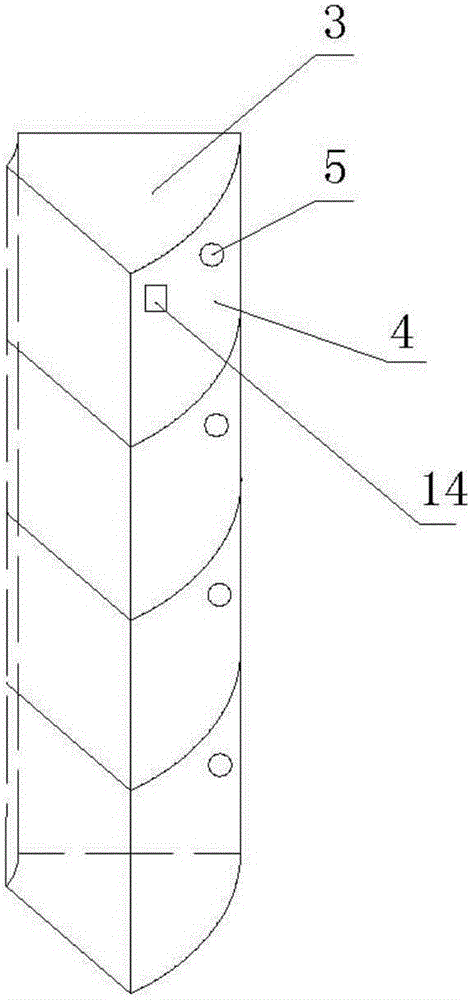

[0019] like Figure 1-3 Shown, a kind of time-delay sample dividing liquid sampler of the present invention comprises rotating chassis 1, test tube clamping groove 2, test tube 3, sample storage tube 4, columnar switch 6 and PLC controller 15, several test tube clamping grooves 2 ( The present embodiment adopts 6 test tube slots) to be evenly distributed on the rotating chassis 1 along the circumferential direction, as figure 2 As shown, a test tube 3 is arranged in each test tube slot 2, and several sample depositors 4 are uniformly arranged in the test tube 3 along the length direction (4 sample depositors are adopted in the figure). A sampling port 5 corresponding to the sample storage device 4 is provided; a columnar switch 6 is provided on the outside of the test tube slot 2, and the columnar switch 6 covers all the test tube slots 2 therein. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com