Glass-bending device and glass-bending method using a fan

A bending device and bending technology, applied in glass production, glass molding, glass manufacturing equipment, etc., can solve the problems of high energy consumption, complex cost, dense, etc., and achieve the effects of saving energy, simplifying the technical structure, and avoiding air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

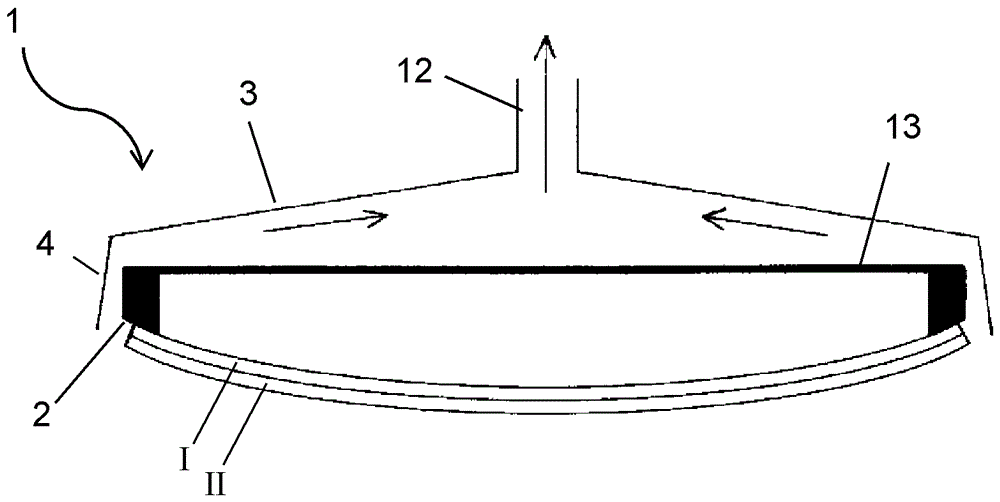

[0051] figure 1 A known tool 1 (holding tool) for holding at least one glass pane by suction is shown. The tool 1 is an upper mold, which is suitable for holding two superimposed glass panes I, II against the influence of gravity by means of suction on a frame-shaped convex contact surface 2 . The contact surface 2 is arranged on a so-called frame 13 . To generate the suction effect, the tool 1 includes a suction duct 12 through which air is sucked out. The tool additionally has a cover plate 3 , the end of which is equipped with a surrounding wind deflector 4 . The wind deflector 4 surrounds the contact surface 2 circumferentially. By bending the frame 13 and the cover 3 with the wind deflector 4 , the air flow generated by the suction duct 12 is guided such that it brushes over the edge of the glass pane. As a result, the glass pane pair I, II is held securely at the contact surface 2 .

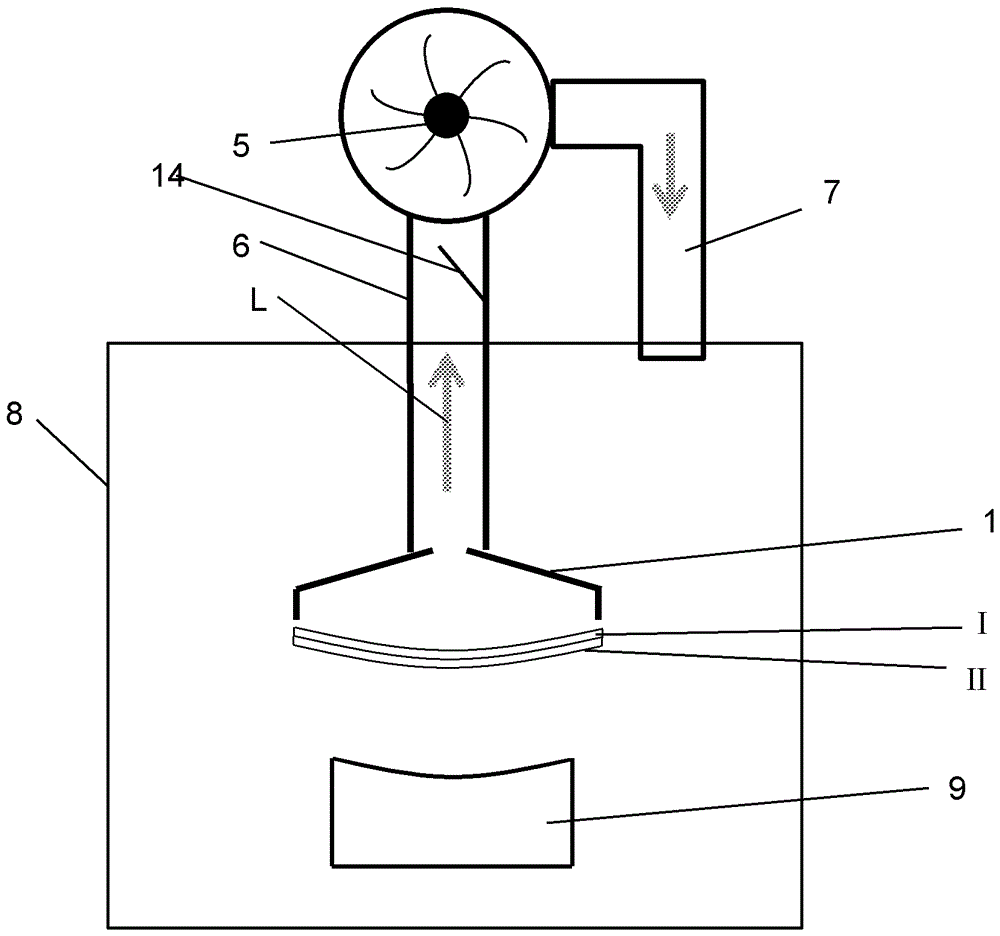

[0052] The glass sheets I, II are prebent, for example by gravity bending in the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com