Thread laying drive, especially for working station of textile machine

A motor drive, drive technology, applied in the direction of thin material handling, delivery of filamentous materials, transportation and packaging, etc., can solve problems such as unresolved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

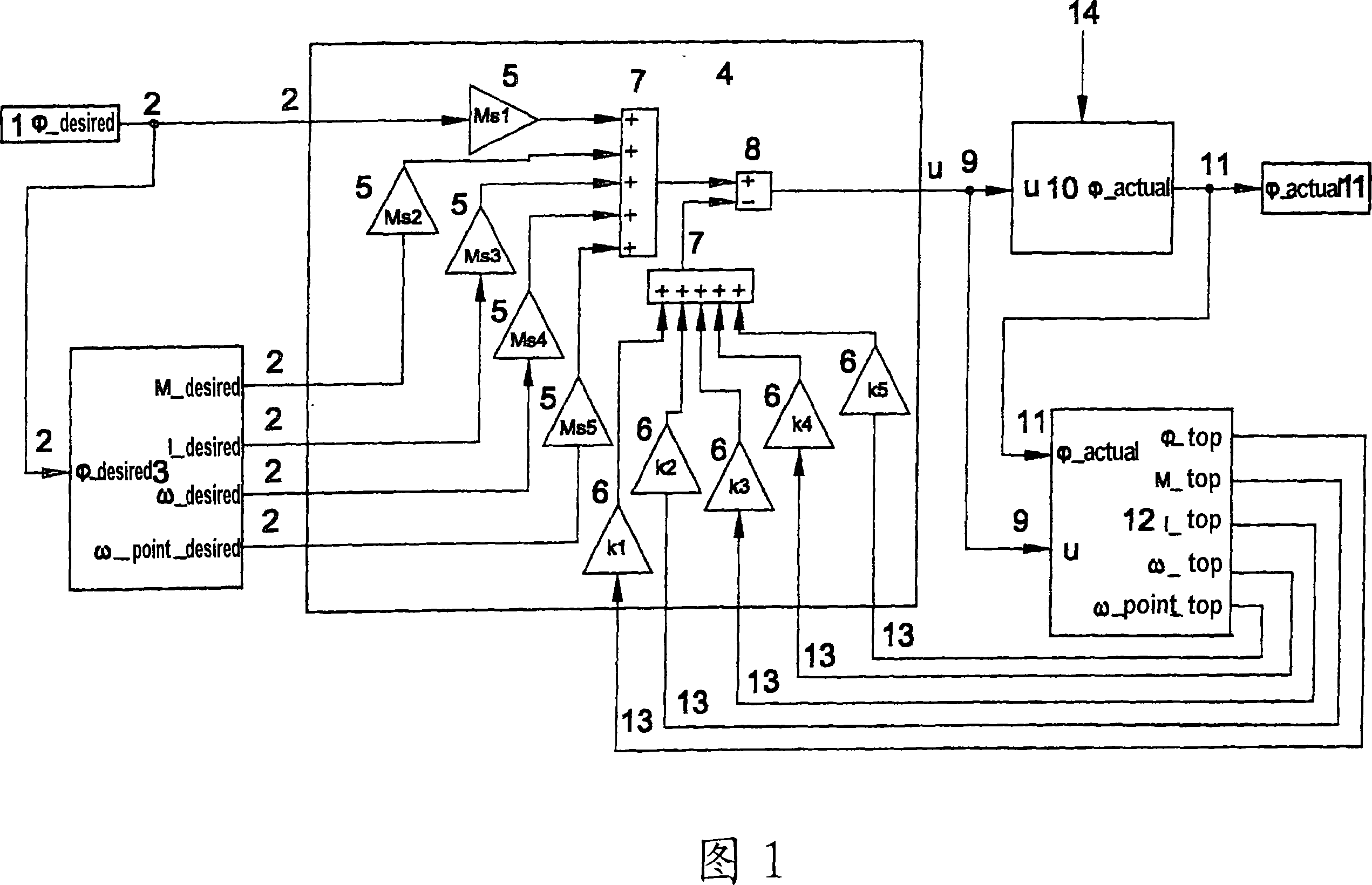

[0026] FIG. 1 shows a block diagram for a control structure of a yarn displacement drive with a state observer 12 . In this case, the predetermined angular position ([phi]_desired) enters the controller 4 directly from the desired value sensor 1 as the desired variable 2 . This angular position ([phi]_desired) is also used as an input variable in part Model 3. Using the partial model 3, the real control section 10 including the yarn guide drives and other electromechanical yarn displacement drives is described as an ideal control section. Therefore, further desired variables 2, namely the corresponding torque (M_desired), the required displacement current (I_desired), the corresponding angular velocity (ω_desired) and the corresponding angular acceleration (ω_point_desired) of the yarn guide, can be generated as parameters of the controller 4 Other input variables. Within the controller 4 , each input desired variable 2 can be individually weighted by means of a respective w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com