High-speed turnout rail hot forging forming rotary rail auxiliary feeding device

An auxiliary feeding and rotary technology, applied in forging/pressing/hammer devices, vehicle parts, transportation and packaging, etc., can solve the problems of reducing the rotational resistance of rail parts, and achieve stable structure, reasonable structure, and convenient installation and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical scheme of the present invention will be further explained below in conjunction with the drawings.

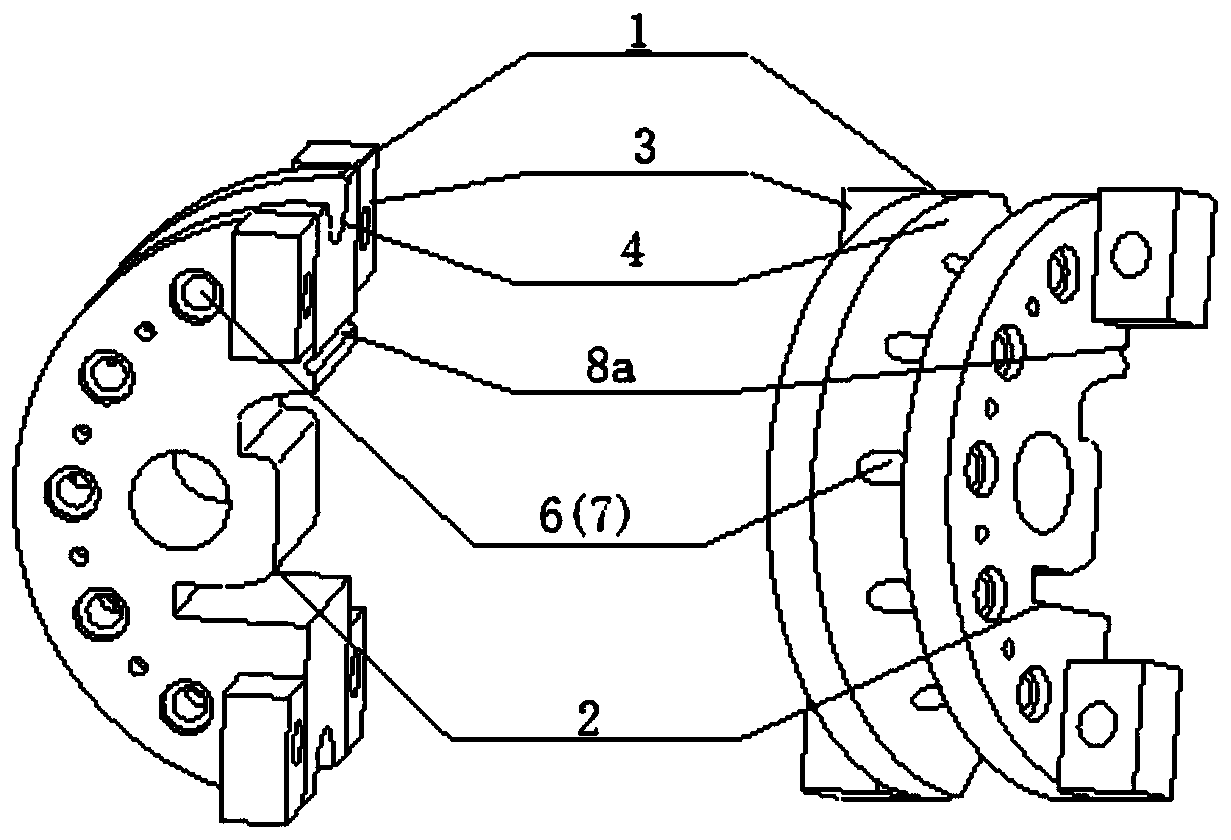

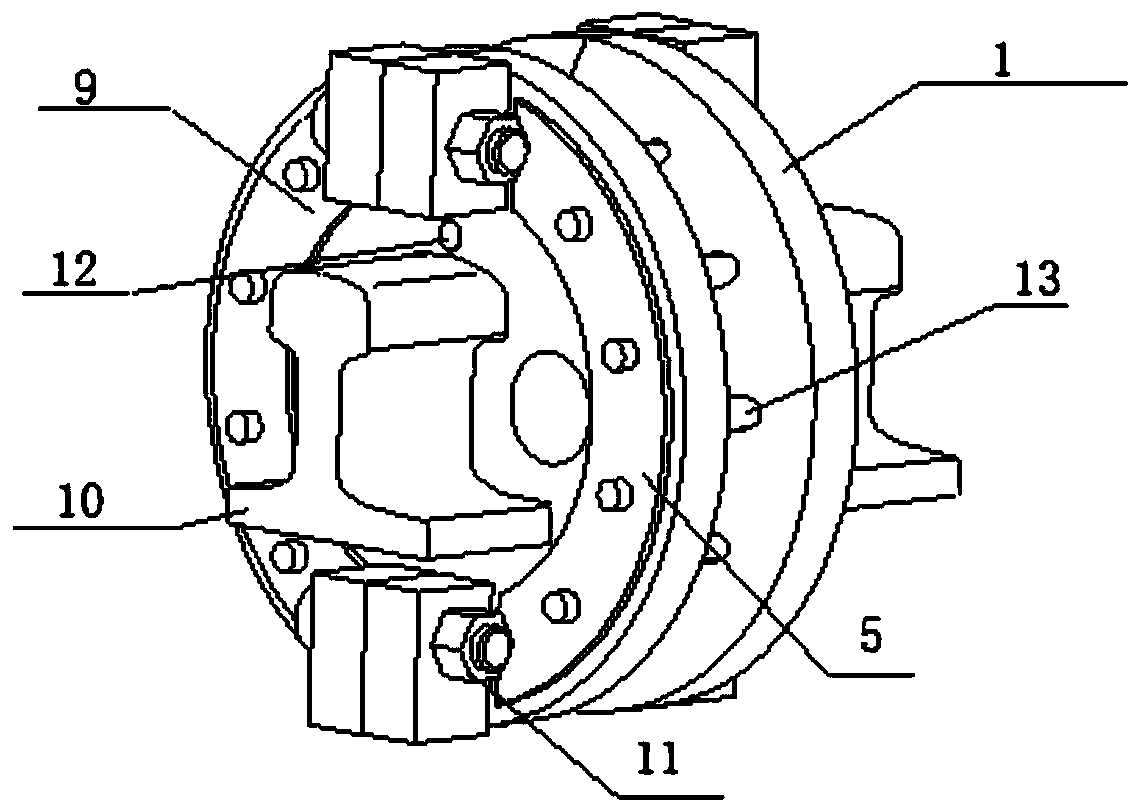

[0028] Such as figure 1 As shown, the long-leg hoisting rotating clamp 1, the long-leg hoisting rotating clamp 1 has a semi-circular arc shape, and the long-leg hoisting rotating clamp 1 is the profiling contour of the long-leg side of the rail member. 1 The two ends of the semicircular diameter part are provided with fastening bolt blocks 3, and the long-limb lifting and rotating clamp is provided with rope groove installation parts 4; the end surface of the long-limb lifting and rotating clamp is provided with a rolling bearing end cover 5, The shaft 6 is installed in the rolling bearing end cover 5 and in the bearing installation hole 7 of the long-limb lifting and rotating clamp 1. The long-limb hoisting rotary clamp 1 is provided with a semi-circular sewing pin hole 8a at the combined interface. When the long-limb hoisting rotary clamp 1 and the short-limb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com