A safety system for raising and lowering joints of a tower crane

A system-wide, safety-reducing technology, applied to cranes and other directions, to achieve the effect of reducing the incidence of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

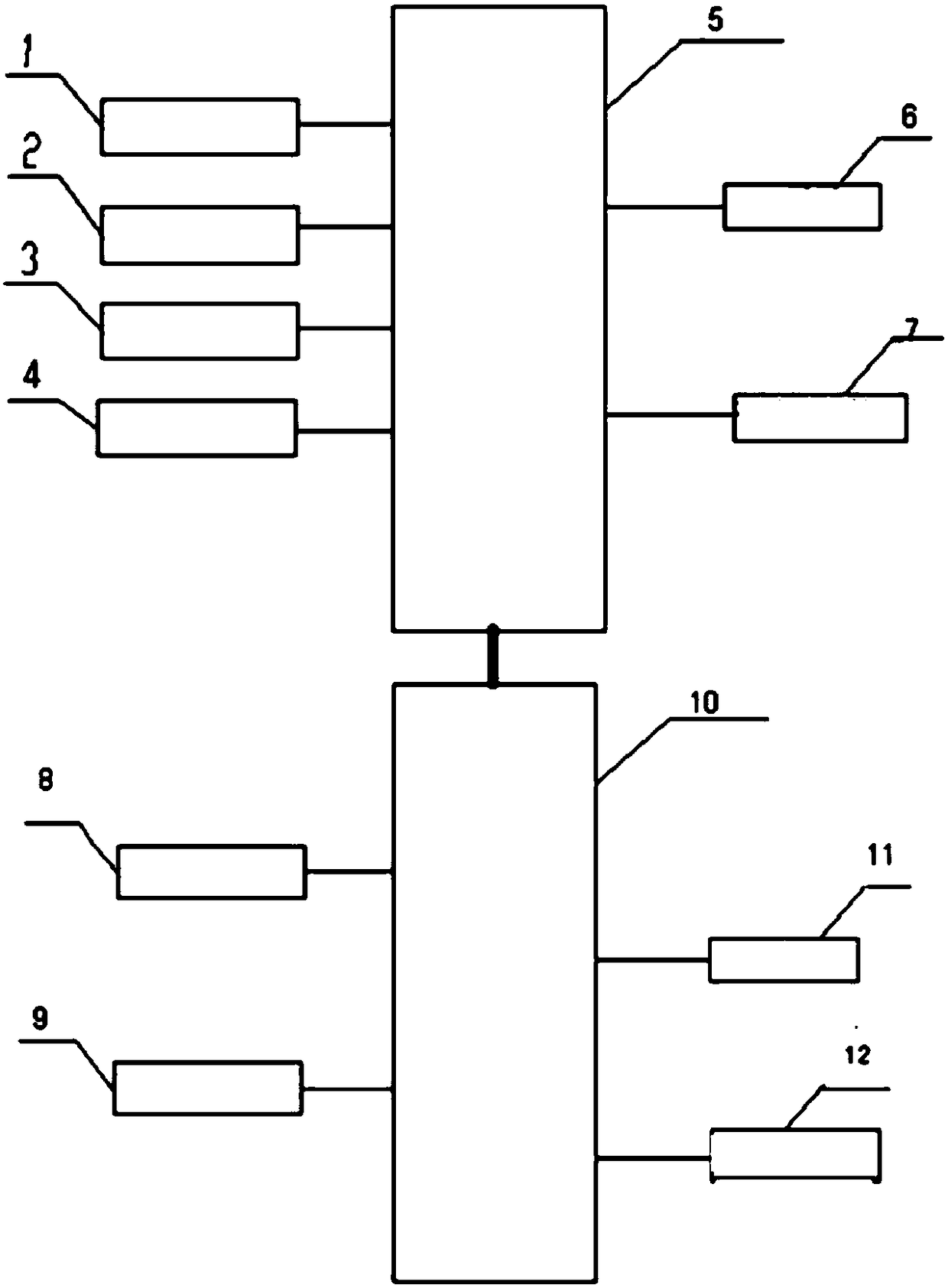

[0017] Such as figure 1 As shown, a safety system for raising and lowering joints of a tower crane includes a connected main control unit 5 and a hydraulic cylinder control unit 10;

[0018] A first acceleration sensor 1, a wind speed sensor 2, an inclination sensor 3, a first driver's card reader 4, a first display screen 6 and a strong current control unit 7 connected to the main control unit 10;

[0019] A second acceleration sensor 8 , a second driver card reader 9 , a second display screen 11 and a height sensor 12 connected to the hydraulic cylinder control unit 10 .

[0020] The first acceleration sensor is installed on the hoisting handle of the tower crane, and is used to collect the gear position information of the lifting handle; the wind speed sensor is installed on the boom of the tower crane, and is used to collect the wind speed of the working environment of the tower crane; the inclination measurement The device is installed on the main limb transition joint o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com