A kind of gray dye, dye composition and application thereof

A dye composition and dye technology, which is applied in the field of dye composition and gray dyes, can solve the problems of unstable process, low level dyeing property and difficult washing, and achieve easy washing, high level dyeing property and good color fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

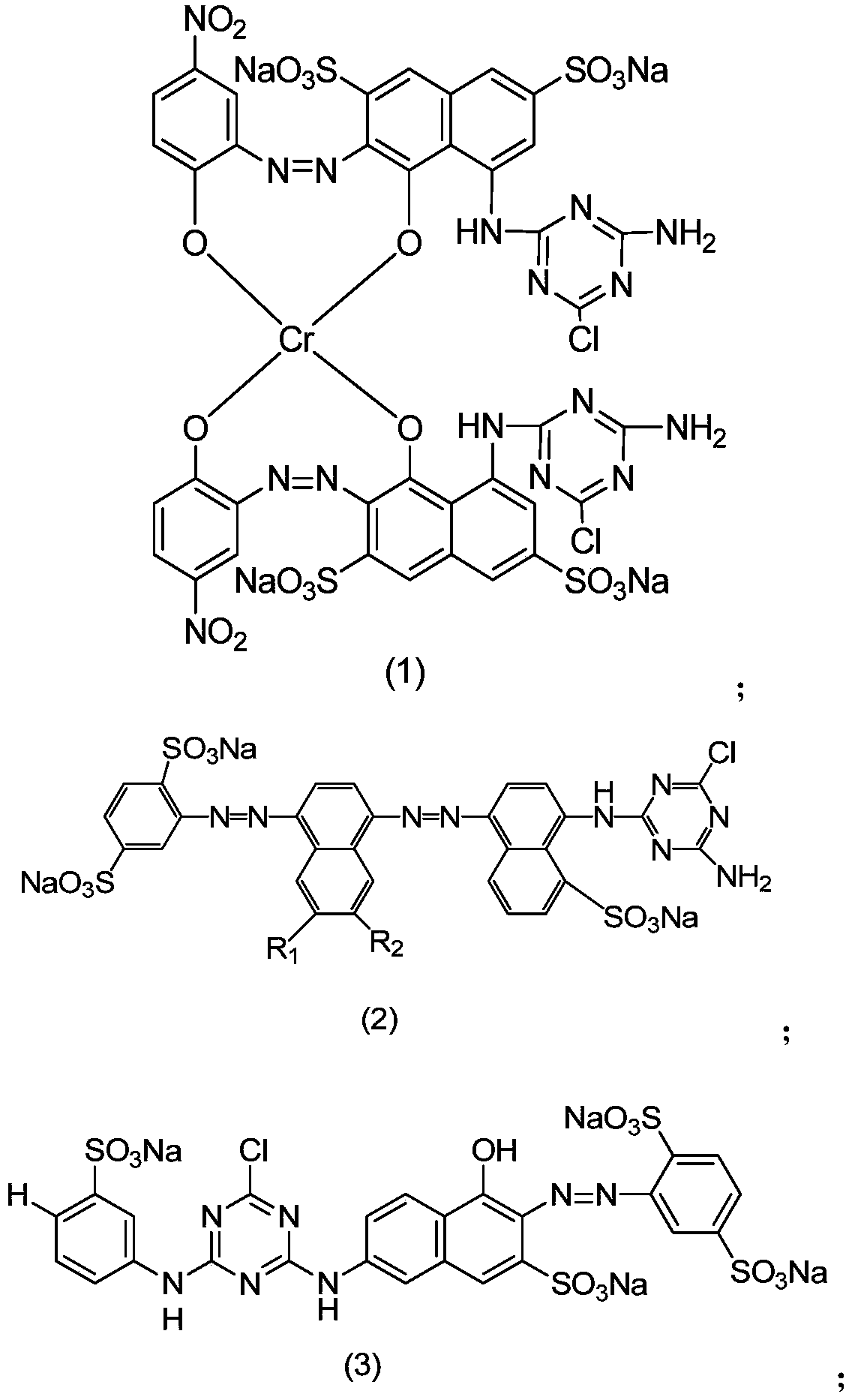

Method used

Image

Examples

Embodiment 1~9

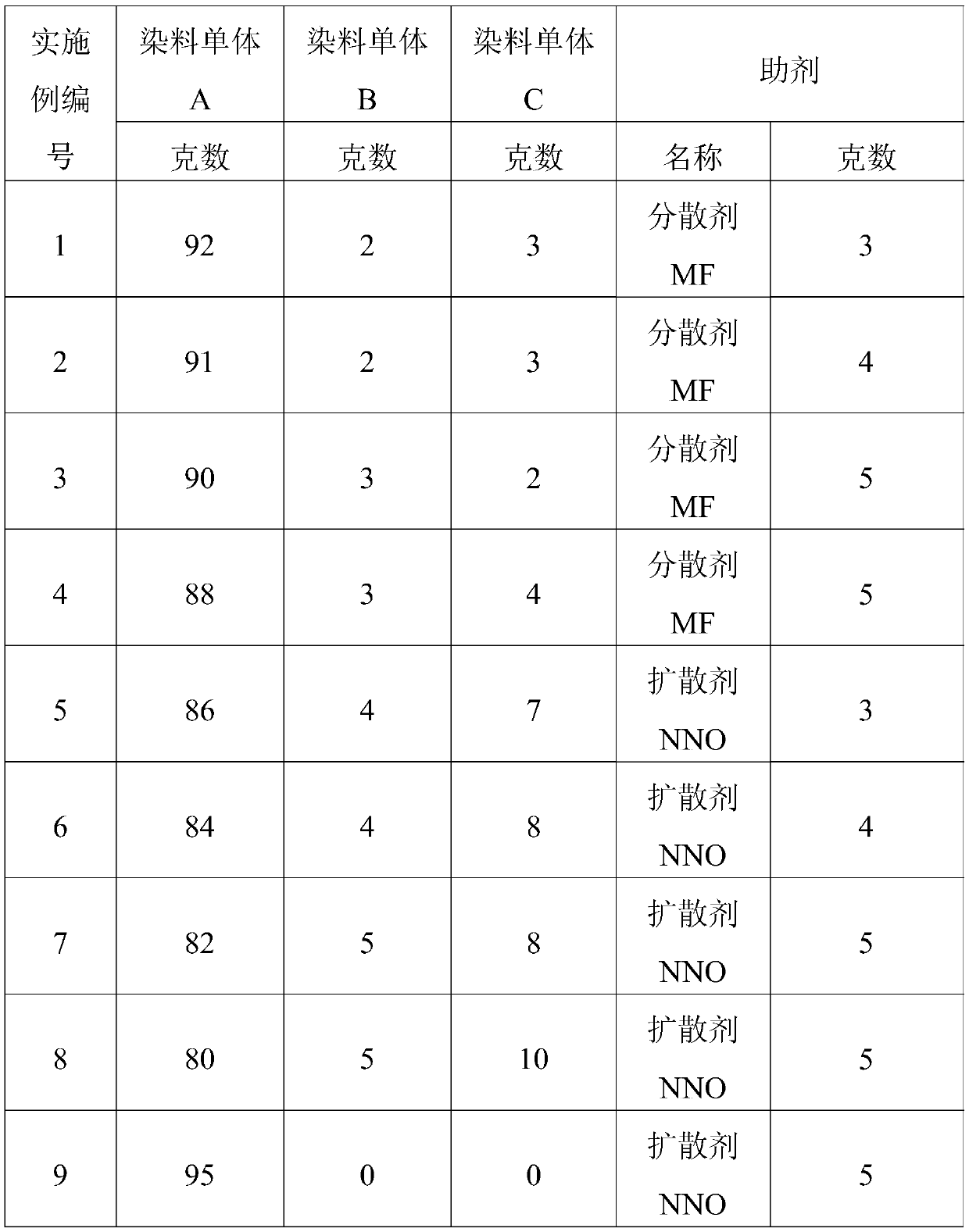

[0026] According to the ratio method in Table 1, the dye monomer A, dye monomer B, dye monomer C and co-solvent can be mixed. The monomer powder blending method commonly used in this industry can be used, and powder blending needs to be guaranteed The bottom material is returned to the top three times, and the total mixing time is 3 hours. The above mixing methods are all sampled and tested from the top, middle and bottom of the container, and the depth difference is required to not exceed 2%;

[0027] Table 1

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com