A method for slipping into place of a large-scale soil-covered bullet tank

A bullet and slip technology, which is applied to building types, large-capacity bulk material storages, buildings, etc., can solve the problems of large sand bed size, large self-weight and structural size of soil-covering tanks, and difficulty in hoisting and placing by cranes. Cost saving and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

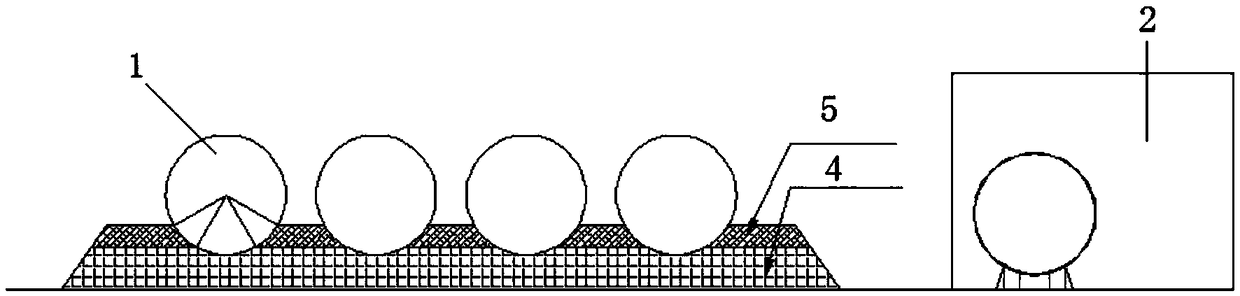

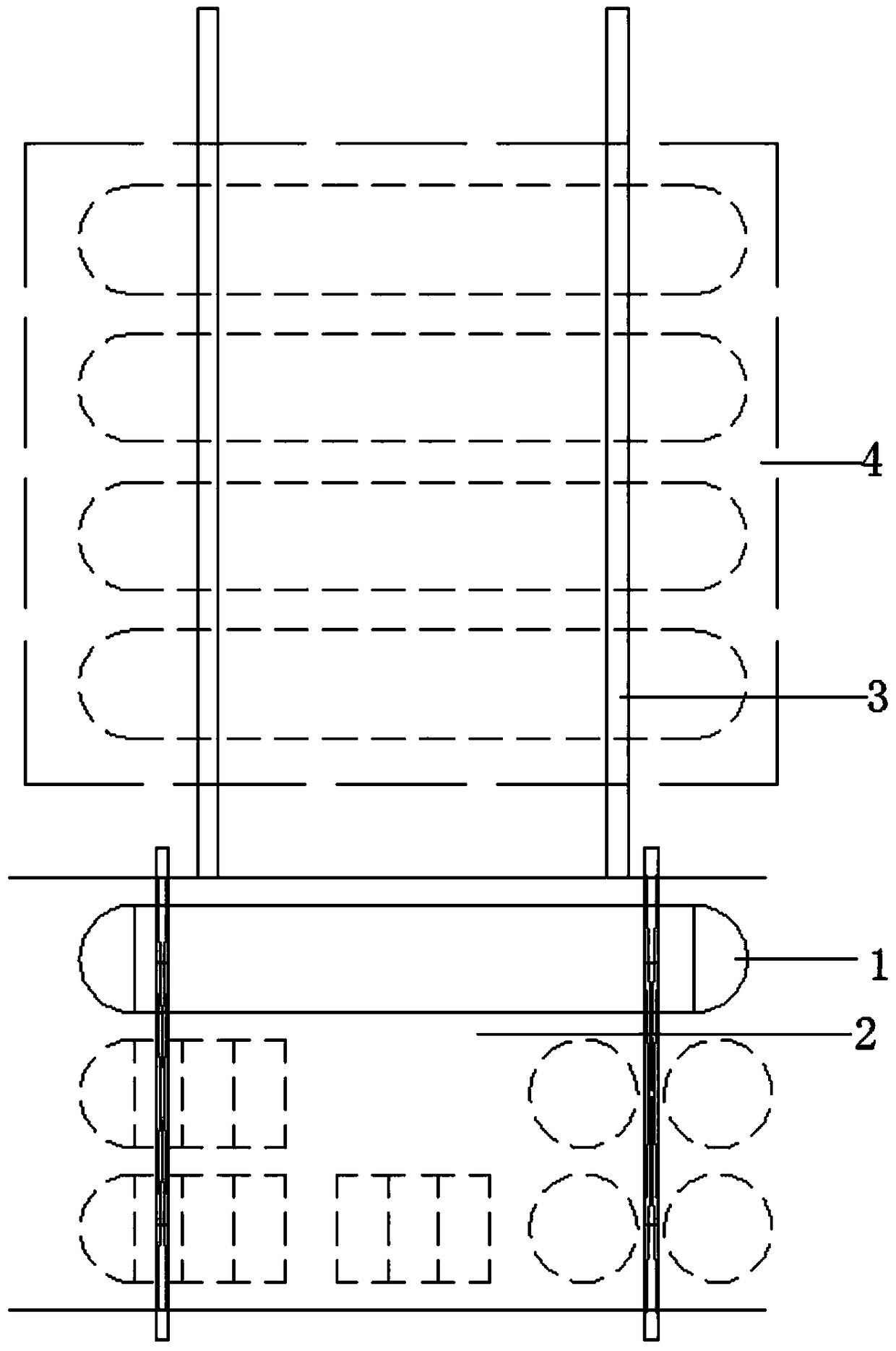

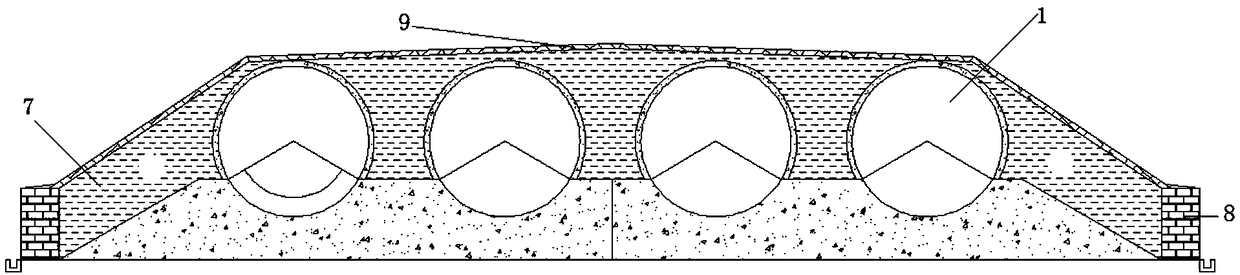

[0038] The technical solutions of the present invention are further described in detail below through the examples and in conjunction with the accompanying drawings, such as Figure 1-14 As shown, a large-scale soil-covered bullet tank sliding into place method is characterized in that: comprising the following steps:

[0039] Step 1. According to the planning and design of the sand bed 4, calculate the elevation difference between the elevation of the on-site welding area 2 and the elevation drop of the bullet tank 1 after the bullet tank 1 is in place on the sand bed 4, such as Figure 4 As shown in the figure, it is assumed that the passable height of the sand bed 4 itself is 3.0m from the ground. Before sliding, the bullet tank 1 should be lifted to a height of 3.0m above the ground, so that it can slide into the sand bed smoothly.

[0040] Step 2. Lifting operation: use the lifting bracket 13 to lift the soil-covered bullet tank 1 to the design height in the on-site weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com