Sterilizing liquid supply method of surface cleaning apparatus

A surface cleaning device and disinfection liquid technology, applied in chemistry and other fields, can solve problems such as user inconvenience, and achieve the effect of convenient installation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

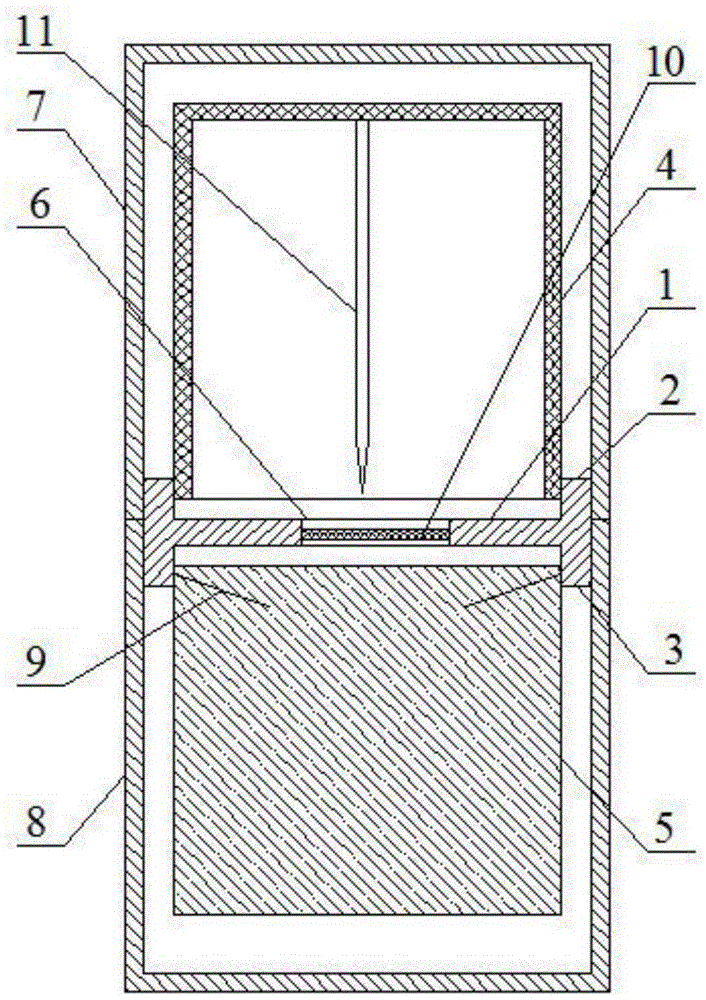

[0027] Such as figure 1 As shown, a method for supplying disinfection liquid to a surface cleaning device, the surface cleaning device includes a partition disc 1, an upper connection ring 2, a lower connection ring 3, a hollow rubber column 4 with an open bottom, a sponge column 5 and a puncture Pin 11; the upper connecting ring 2 and the lower connecting ring 3 are respectively arranged on the upper and lower surfaces of the separating circular plate 1, and the outer circular surfaces of the upper connecting ring 2 and the lower connecting circular ring 3 are all connected with the outer circular surface of the separating circular plate 1 flush; the bottom of the hollow rubber column 4 is fixed on the inner surface of the upper connection ring 2, the top of the sponge column 5 is fixed on the inner surface of the lower connection ring 3, and the bottom of the sponge column 5 is lower than the lower surface of the lower connection ring 3 , the center of the separating circula...

Embodiment 2

[0032] Such as figure 1 As shown, on the basis of Embodiment 1 in this embodiment, the surface cleaning device also includes an upper sealing cover 7 and a lower sealing cover 8, and the bottom inner surface of the upper sealing cover 7 and the top inner surface of the lower sealing cover 8 are provided with Internal threads, the upper connecting ring 2 and the outer circular surface of the lower connecting ring 3 are provided with external threads; the upper sealing cover 7 completely covers the hollow rubber column 4 and is threadedly connected with the upper connecting ring 2; the lower sealing cover 8 completely covers The sponge column 5 is also threaded with the lower connecting ring 3;

[0033] In the disinfection liquid supply method, before pressing the top of the hollow rubber column 4, the step of removing the upper sealing cover 7 and the lower sealing cover 8 is also included.

[0034] The upper sealing cover 7 is provided to prevent the hollow rubber column 4 fr...

Embodiment 3

[0036] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1 or 2, the surface cleaning device further includes a plurality of fixed pins 9 arranged on the inner surface of the lower connecting ring 3 , and the fixed pins 9 are inserted into the sponge column 5 .

[0037] The fixing pin 9 is provided to make the connection between the sponge column 5 and the lower connection ring 3 more reliable, and to prevent the sponge column 5 from falling off during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com