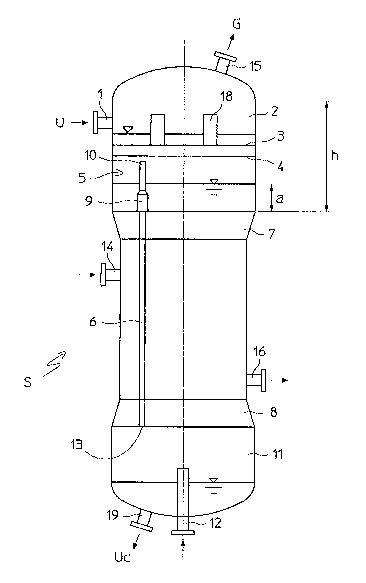

Falling-film stripper for carbamate decomposition

A technology of carbamate and stripper, applied in the direction of separation method, distillation separation, tube still, etc., can solve the problems such as unable to support the increased flow rate, and achieve the effect of effective quantity and size, and compact overall design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

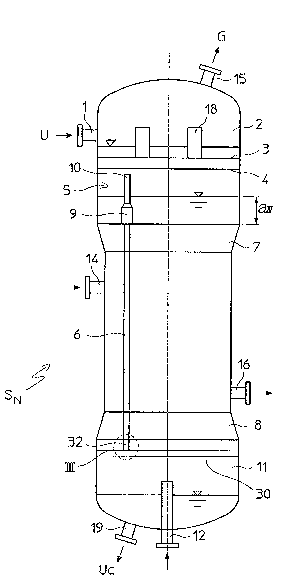

[0033] Such as figure 2 Shown is the stripper S of the present invention N . Those features that are common to the existing stripper diagram in Figure 1 are indicated by the same reference numerals and only new features are discussed here.

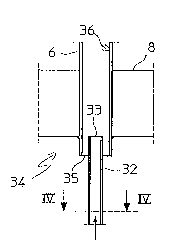

[0034] In the bottom liquid header box 11, the stripper S of the present invention N There is a perforated plate tray 30 with liquid drain holes 31 ( Figure 4) and carry a plurality of chimneys 32 . Each chimney 32 is a tube smaller than the main bundle tube 6 and has a bottom end connected to the tray 30 and a top portion 33 which enters the respective tube 6 and communicates with the chamber 11 , and above the bottom portion 34 of the tube 6 ( image 3 ).

[0035] according to Figure 5 In the embodiment, the gas riser 32 is supported by a tray 30a, and the tray 30a has no liquid drainage holes. The concentrated urea solution Uc gathers at the tray 30 a and overflows from the downcomer 37 .

[0036] At said bottom end portion 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com