Construction technology for deep soft foundation treatment

A construction technology and soft foundation treatment technology, which is applied in the direction of foundation structure engineering, soil protection, sheet pile walls, etc., can solve the problems of difficult to meet the post-construction settlement and bearing capacity requirements of deep soft foundation areas, high engineering cost, etc., to achieve Solve the problem of foundation bearing capacity, increase the bearing capacity of single pile and composite foundation, and improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

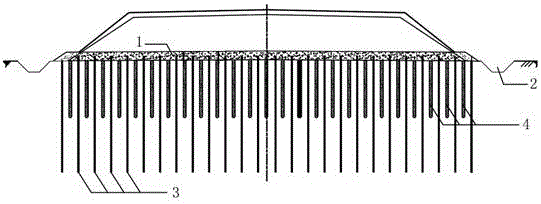

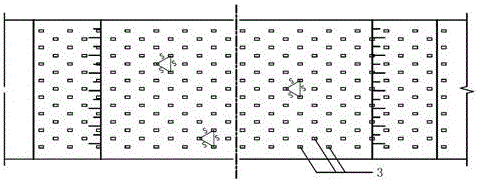

[0037] Such as figure 1 As shown, the present invention discloses a construction process for treating deep and thick soft foundations, which is characterized in that the construction process uses plastic drainage boards 3 for deep pretreatment, and then uses cement mixing piles 4 for secondary shallow reinforcement treatment. Specifically includes the following steps:

[0038] Calculation of ground treatment parameters:

[0039] In this process, the upper silt is reinforced with cement mixing pile 4, and the settlement control of deep silt is treated with plastic drainage board 3. The calculation model is divided into the upper soft soil layer using the composite foundation reinforcement area, and the lower soft soil layer as the drainage preloading treatment area. The foundation bearing capacity and settlement of different reinforced soil layers are calculated as follows:

[0040] Settlement Calculation:

[0041] The settlement of the foundation is based on the settlement ...

Embodiment 2

[0059] This embodiment is based on the construction process steps described in Embodiment 1, and takes the Gangbei Road (west section) project in Xiamen City as the construction object for implementation verification.

[0060] The road is an urban main road with a total length of 1.445km. The original landform unit of the road section is the bay tidal flat. There are generally deep soft foundations over 12m in depth, and the deepest silt is about 20m. The original design uses CFG piles to deal with the deep penetration of silt. , the plane layout adopts an equilateral triangle layout, the spacing is 1.4m, the average treatment depth is about 18m, and the average cost per square meter is about 630 yuan. After adopting the process of the present invention, the plastic drainage board 3 has an average treatment depth of 18m, and the plane layout adopts a spacing of 1.2m and an equilateral triangle arrangement. The cement mixing pile 4 carries out secondary treatment depth of 10m, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com