Adjustable sliding-rail type suspension girder operating platform for high-rise building

A technology for operating platforms and high-rise buildings, applied in the directions of buildings, building structures, housing structures, etc., which can solve the problems of leaning, poor comfort, and poor safety of the operating platform, and improve safety, which is not easy. The effect of shaking and reducing fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

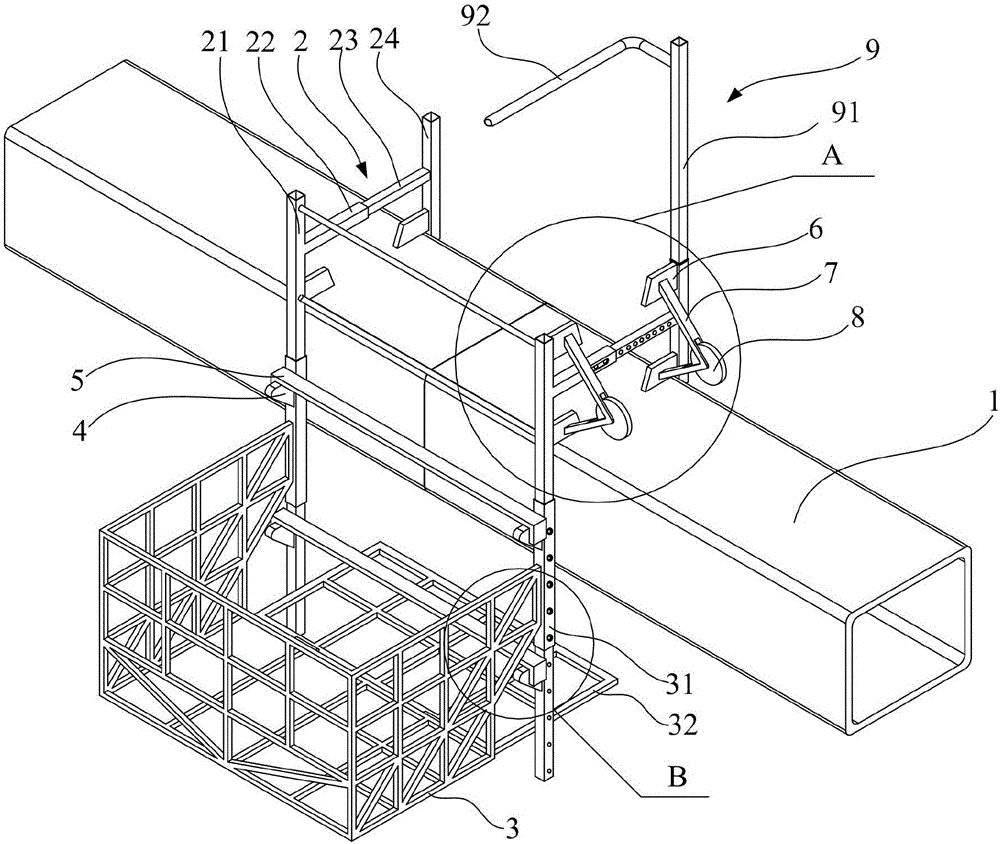

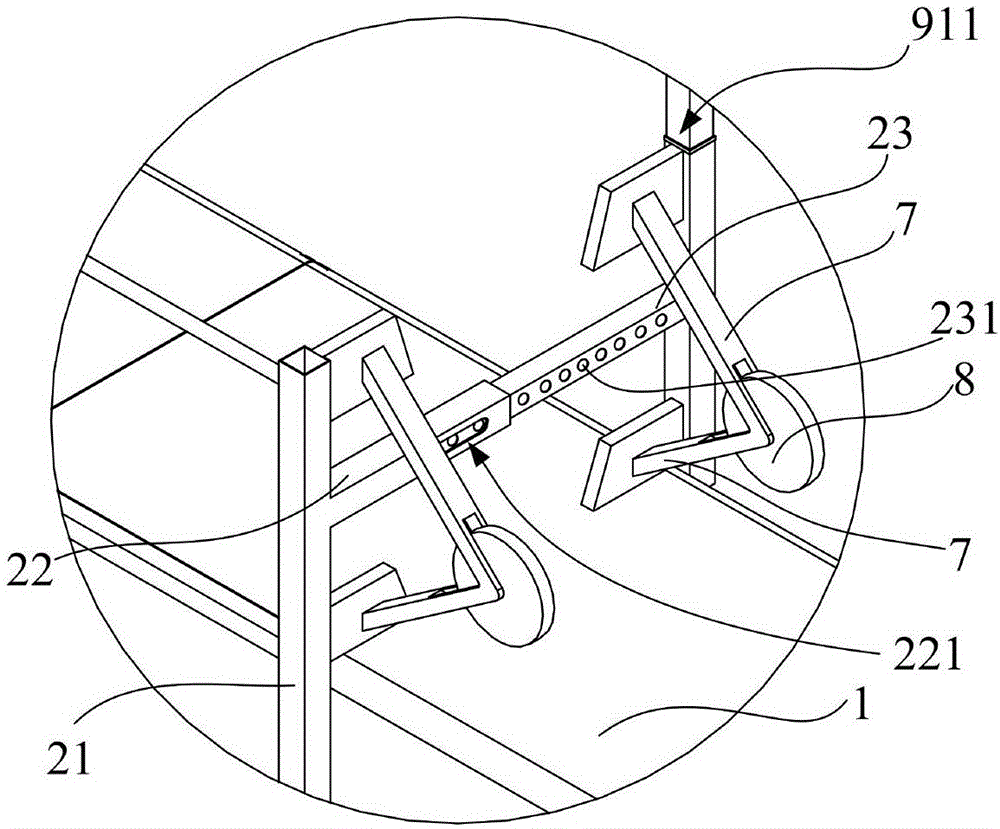

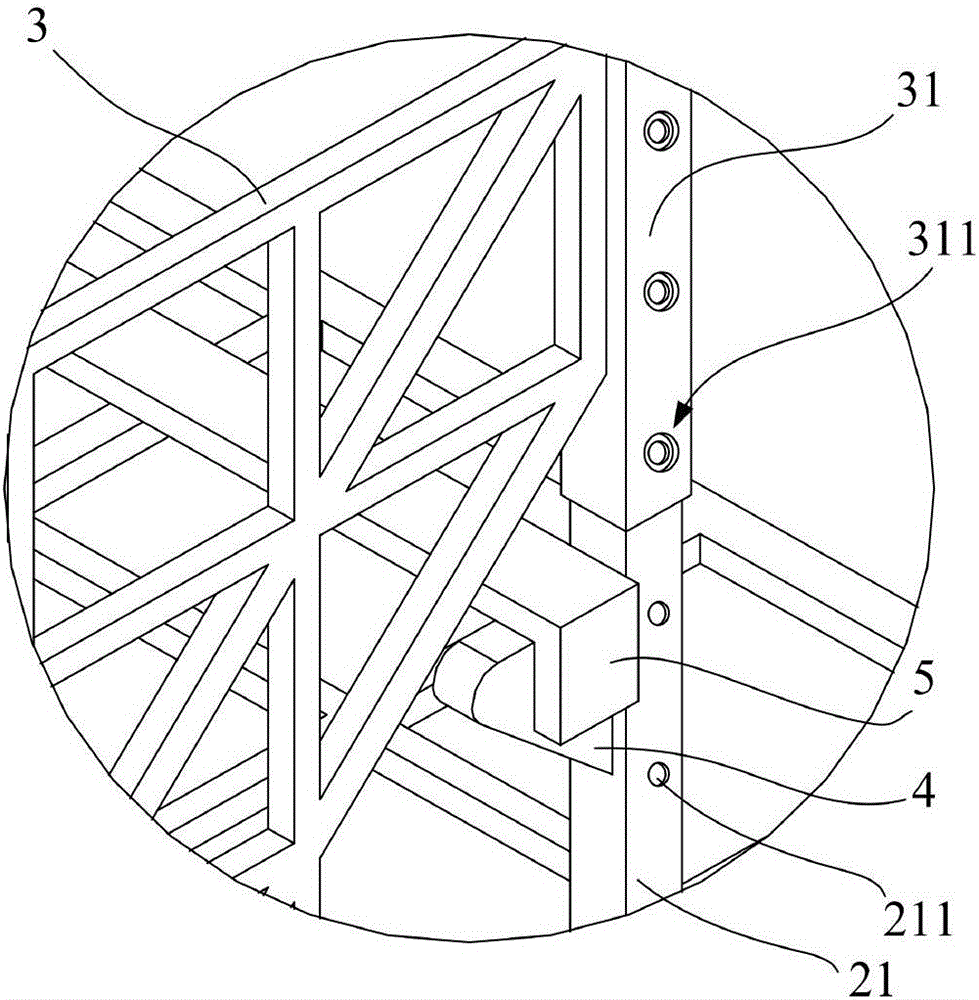

[0034] See Figure 1 to Figure 4 , the present invention proposes an adjustable slide rail type suspension beam operating platform for high-rise buildings, the operating platform includes a basket frame body 3 and a hook structure arranged on the left and right sides of the basket frame body 3 facing the suspension beam and can hang the operation platform on the suspension beam 1 2. The hook structure 2 includes a telescopic crossbeam that can be stretched and adjusted in length, and a front clamping arm 21 and a rear clamping arm 24 that are vertically and fixedly connected to the telescopic crossbeam. Among them, the telescopic crossbeam of this embodiment is a segmented structure, including a front crossbeam 22 and a rear crossbeam 23 that are connected to each other. The front crossbeam 22 and the rear crossbeam 23 are partially nested with each other and the telescopic crossbeam can be adjusted by the telescopic device. at the working length of the cantilever beam 1. The...

Embodiment 2

[0044] This embodiment is the same as Embodiment 1 except for the following features: In this embodiment, the telescopic device used to adjust the working length of the telescopic beam hanging on the suspension beam includes a positioning bump that is arranged in the rear cross beam and can protrude elastically. The bottom of the block is also provided with a spring, and the front beam surface is provided with some positioning through holes to cooperate with the positioning projections to adjust the working length of the telescopic beam.

[0045] In this embodiment, in order to hang the operating platform on the suspension beam, it is necessary to first obtain the cross-sectional width of the suspension beam by means of measurement, etc., and then press the positioning protrusion to make it downward without interfering with the positioning through hole. When the positioning protrusion When the block will not interfere with the positioning through hole, move the front beam away ...

Embodiment 3

[0048] This embodiment is the same as Embodiment 1 except for the following features: the height adjustment device for adjusting the height of the basket frame includes a projection that is arranged inside the front clamping arm and can elastically protrude from the surface, and the bottom edge of the basket sliding sleeve is provided with The groove and the protrusion are positioned in cooperation.

[0049] In this embodiment, when the basket frame needs to be slid vertically, first press the protrusion to make it downward without interfering with the movement of the basket sliding sleeve, and then slide the basket sliding sleeve along the front clamping arm Move in the vertical direction, and when the operating platform is translated in place in the vertical direction, the protrusion will interfere with the groove provided on the bottom edge of the basket sliding sleeve, thereby determining the working height of the operating platform.

[0050] Compared with the operating pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com