Use an industrial endoscope to observe the structure of the internal condition of the valve

An endoscope and industrial technology, which is applied in the field of channel structures reserved for observing the internal conditions of valves with industrial endoscopes, can solve the problems of reducing work efficiency, wasting media, and missing work and time, so as to achieve timely observation and save time. and human and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

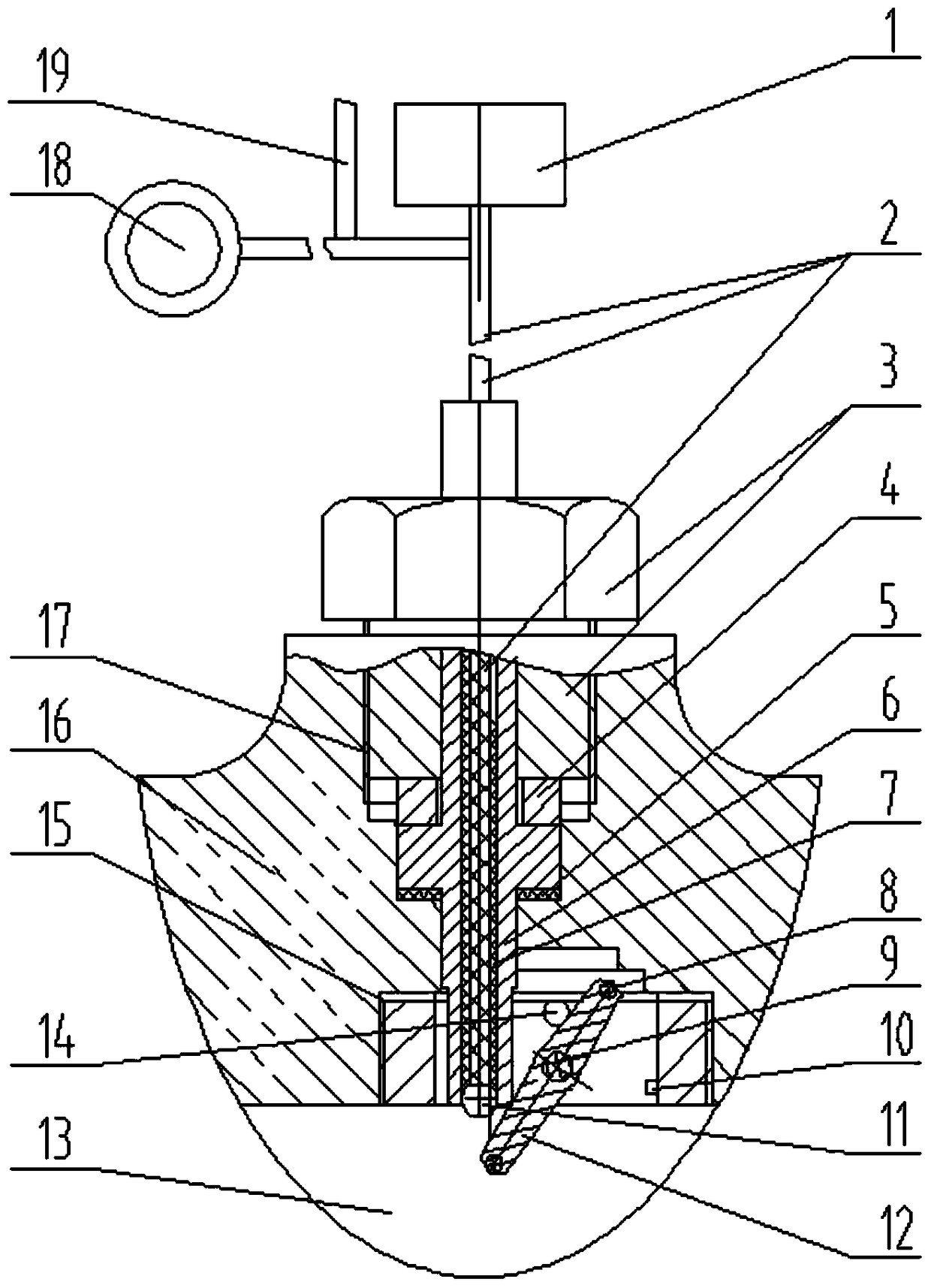

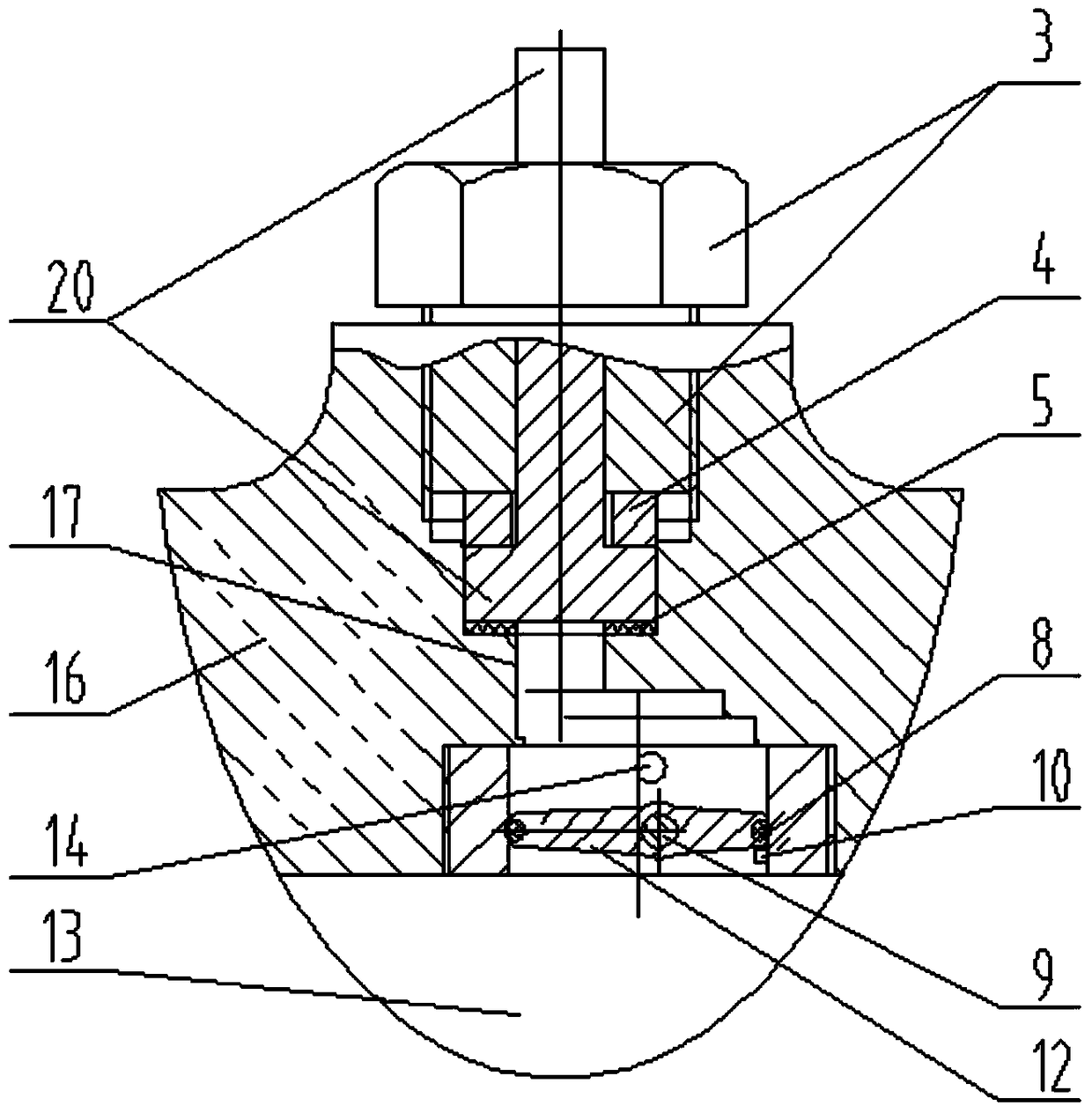

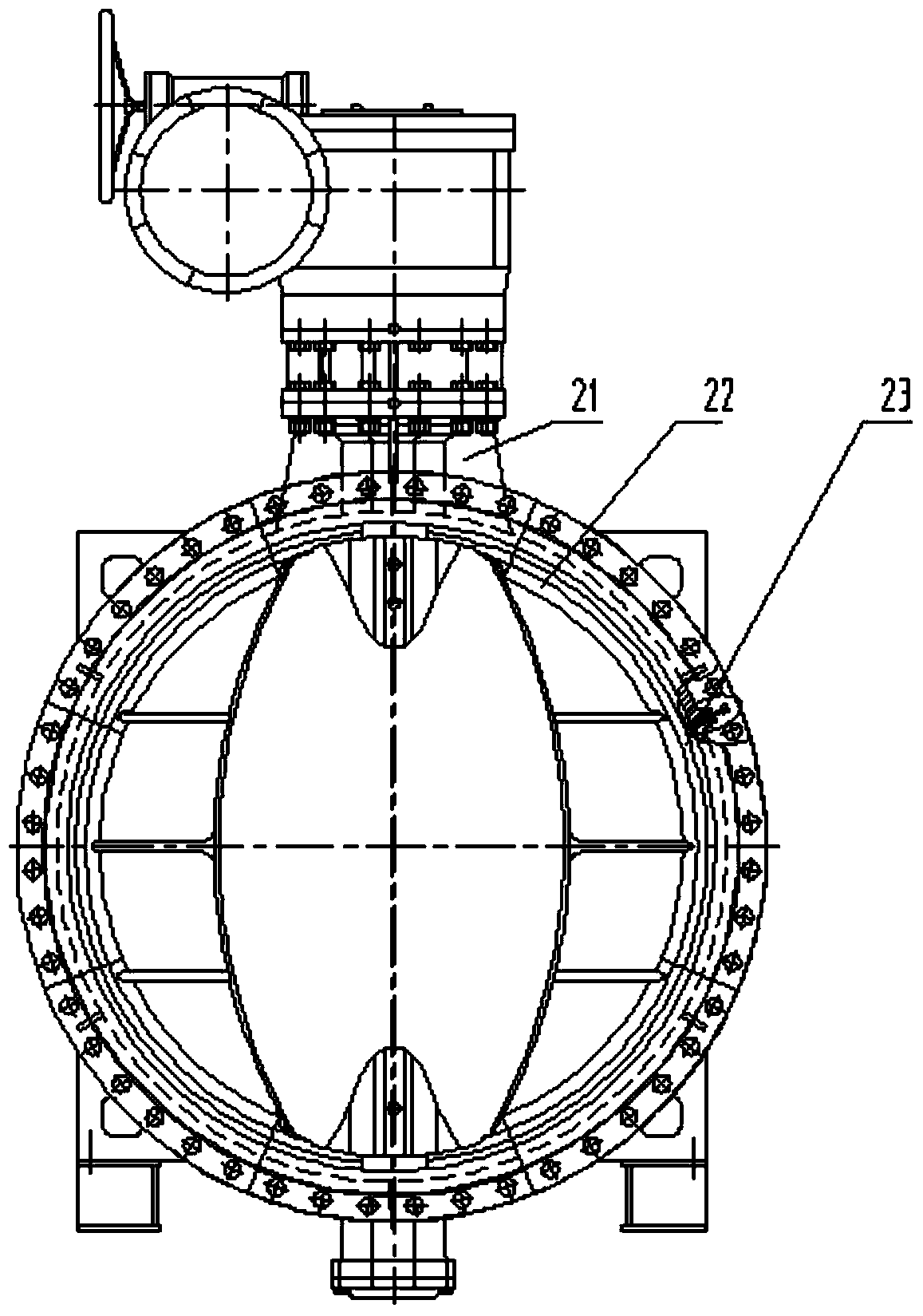

[0022] A channel structure reserved for using an industrial endoscope to observe the internal conditions of the valve, such as figure 1 As shown, the structure includes a through hole 17 made in the valve body 16, an industrial endoscope tip 11 with the functions of light emitting, photographing and data transmission, a conductive light guide 2, a resin sleeve 7, a catheter 6, and is arranged on the valve body. The working eyepiece part 1 outside the body, the shooting transmission part 18 set outside the valve body, the remote data line 19 set outside the valve body and the eccentric butterfly check valve 15, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com