Valve interior observation device with industrial endoscope having photographing and datum transmission functions

A data transmission and observation device technology, applied in the direction of valve devices, engine components, mechanical equipment, etc., can solve the problems of no patent publications, no real-time direct observation, and reduced work efficiency, so as to save time, manpower and material resources, and observe The effect of working in time and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

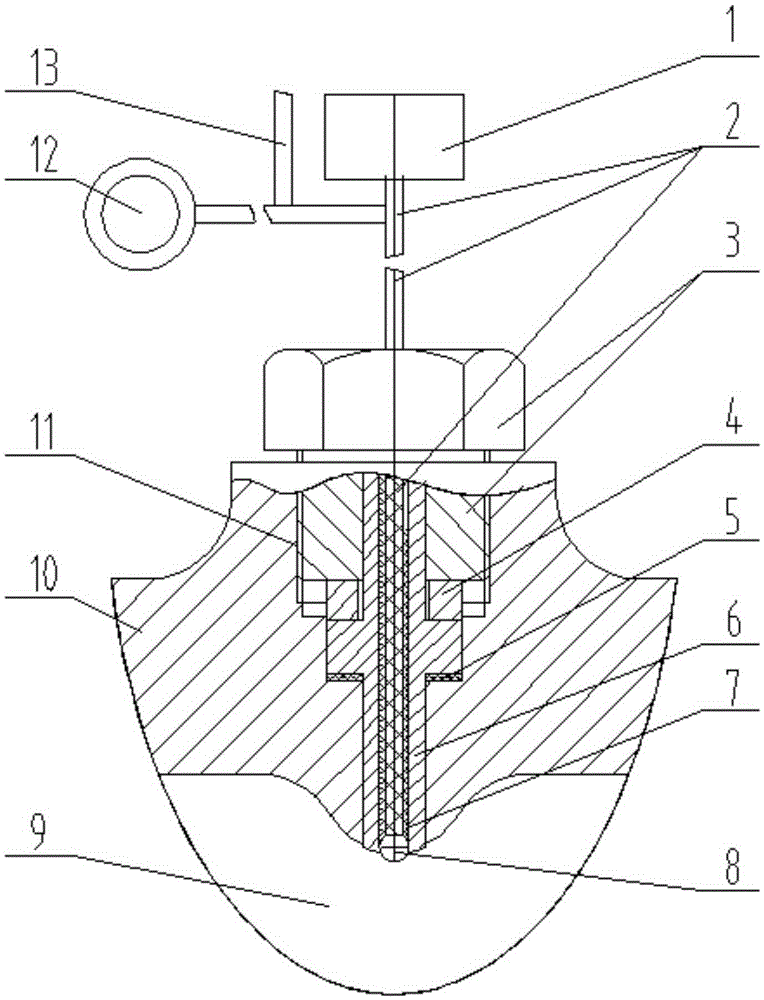

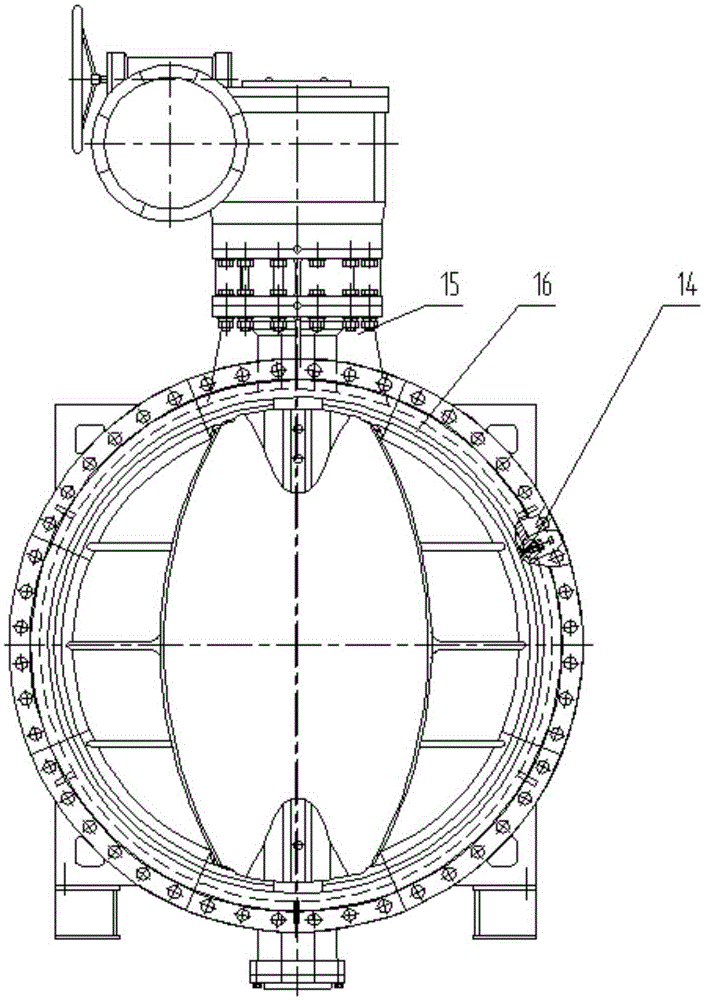

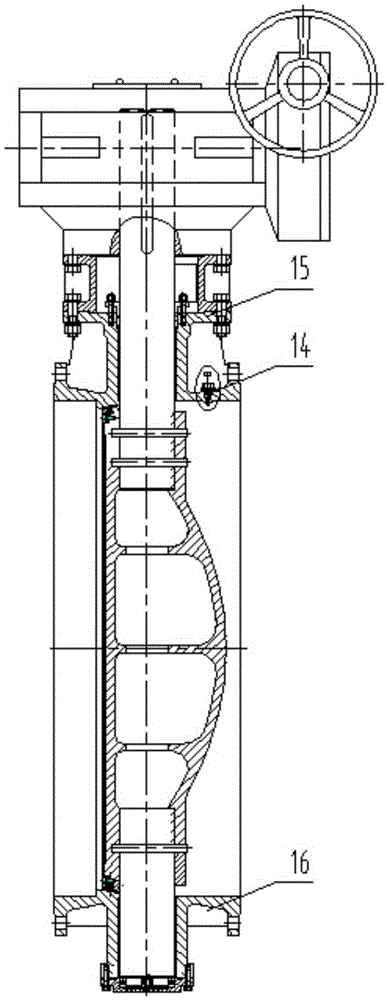

[0016] A valve internal observation device with an industrial endoscope with camera and data transmission functions, such as figure 1 As shown, the device includes a through hole 11 made in the valve body 10, an industrial endoscope tip 8 with functions of light emitting, photographing and data transmission, a conductive light guide 2, a resin sleeve 7, a catheter 6, and is arranged on the valve body. The working eyepiece part 1 outside the body, the shooting transmission part 12 arranged outside the valve body and the remote data line 13 arranged outside the valve body, one end of the through hole communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com