High reliability generator air gap baffle plate quick dismounting device

A generator and reliability technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of narrow space available for operators, discounted generator maintenance effect, small gap between stator and rotor of generator, etc. Achieve the effect of reducing final downtime, light weight, and avoiding the risk of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] A high-reliability generator air-gap baffle quick disassembly device, used to disassemble and install the generator air-gap baffle, the air-gap baffle is equipped with bolts 3 and nuts 4, such as Figure 4 As shown, the bolt 3 is a double-headed hollow bolt with internal threads.

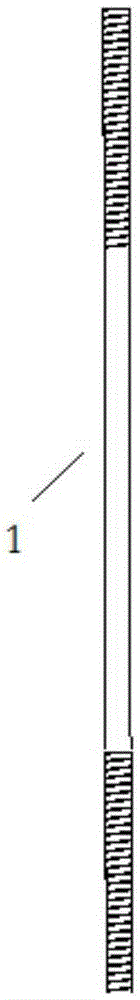

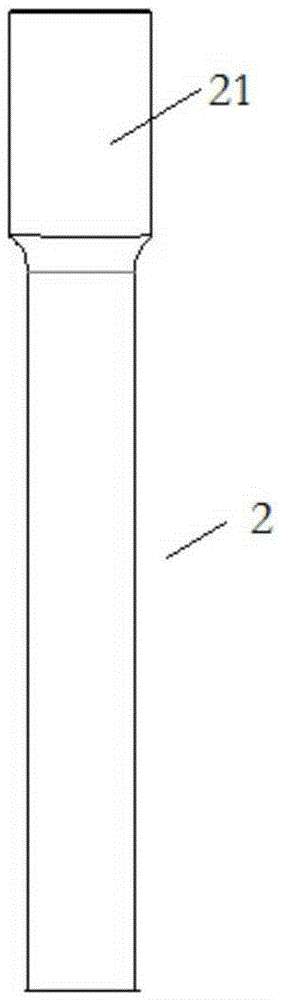

[0028] Such as Figure 1~4 As shown, the tool includes a fixed rod 1 and a sleeve 2. One end of the fixed rod 1 is provided with an external thread 11, and the external thread 11 is matched with the internal thread of the bolt 3. There are multiple fixed rods 1, and each fixed rod 1 is long or short. Different to adapt to different disassembly environments. A nut sleeve 21 is arranged on the sleeve 2, and the shape of the inner wall of the nut sleeve 21 matches the outer wall of the nut 4. For example, the cross-section of the inner wall can be made into a hexagon, and the length of the nut sleeve 21 is greater than the length of the thread of the nut 4, so the nut can be completely wrapped....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com