A method for checking electrical equipment

A technology for electrical equipment and inspection methods, applied in mechanical equipment, televisions, electrical components, etc., can solve the problems of high risk, high labor intensity, low efficiency, etc., to reduce the number of climbing poles, ensure personal safety, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments.

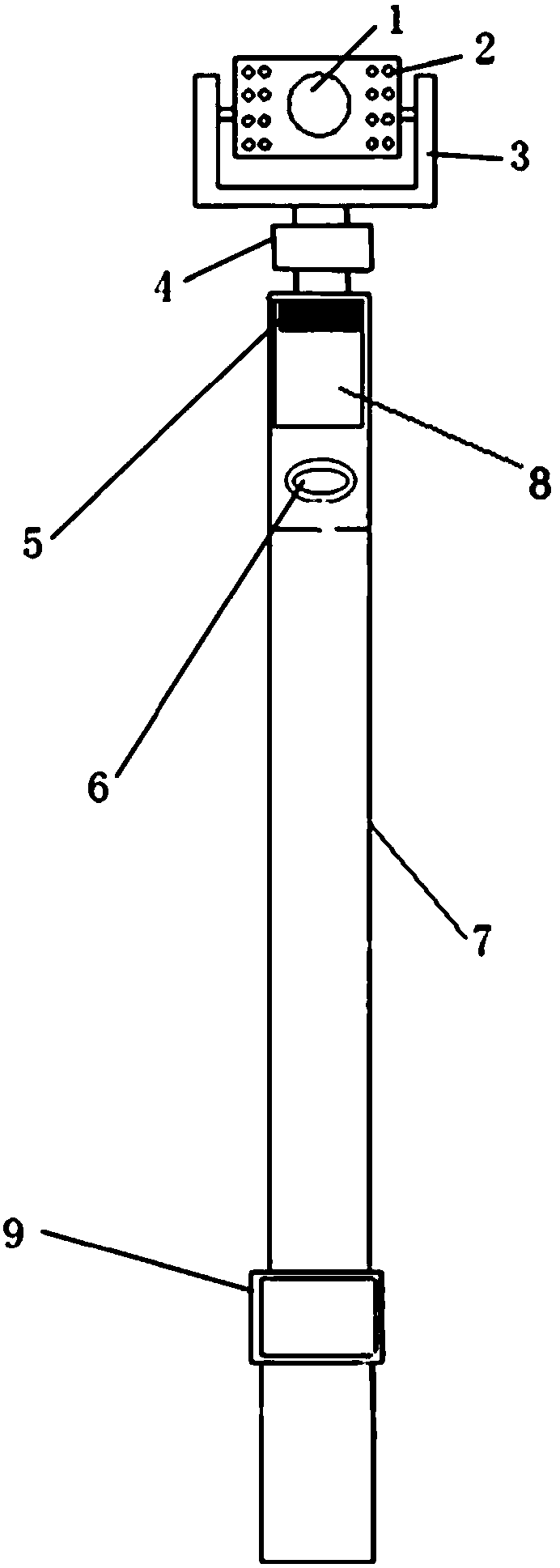

[0031] Such as figure 1 The electrical equipment inspection device shown includes a telescopic rod 7, a bracket 3 fixed on the top of the telescopic rod 7 through a universal head 4, a supplementary light 2 and a camera 1 are fixed on the bracket 3, and the telescopic rod 7 is close to the position of the bracket 3 A cleaning brush 5 is provided, a blower 6 is arranged below the cleaning brush 5, and a display screen 9 is arranged at the bottom of the telescopic rod 7 for real-time display of images taken by the camera. The position where the telescopic tube 7 is adjacent to the cleaning brush 5 is provided with a groove 8, and the telescopic tube 7 and the cleaning brush 5 are connected by a hinge on the edge of the groove 8 so that the cleaning brush 5 can enter and be accommodated when rotating around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com