Slurry lifting device of multi-functional dough skin machine and the dough skin machine

A multi-functional, pastry machine technology, applied in food science and other directions, can solve the problems of falling to the ground, unable to form a round dough, waste of raw materials, etc., to avoid waste, and to achieve the effect of good shape of the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

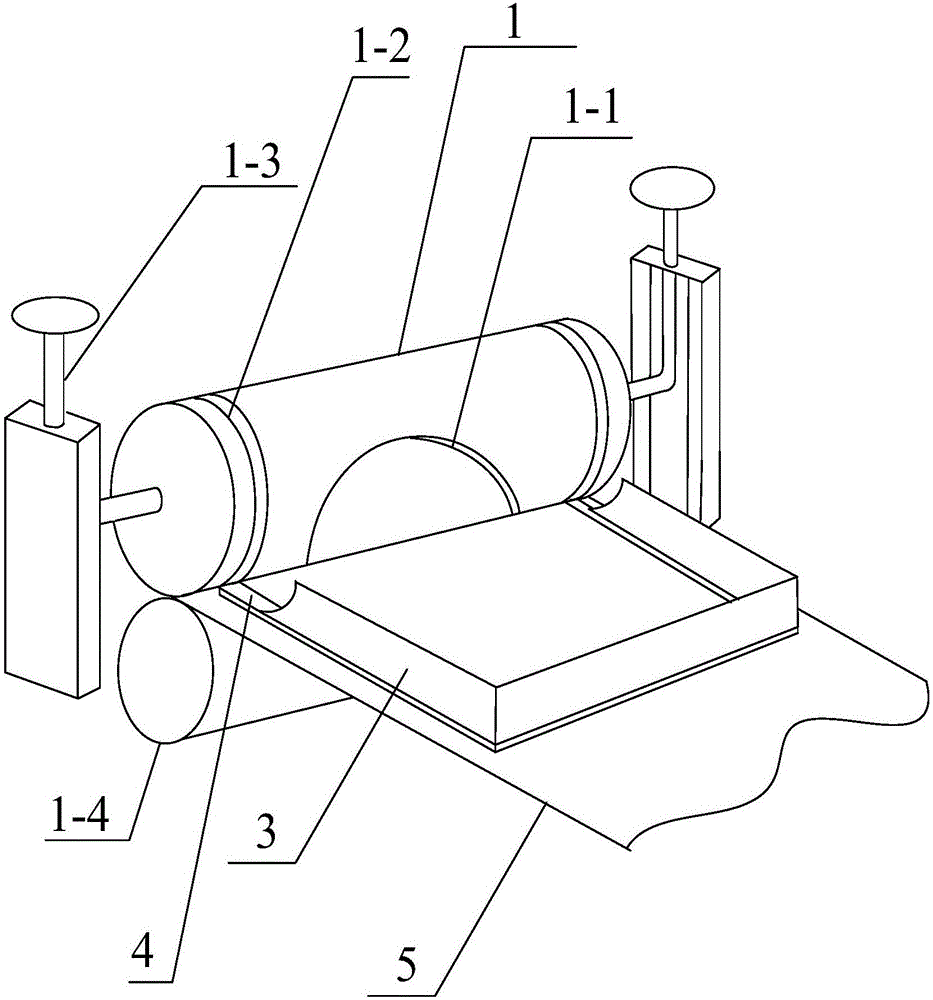

[0027] like figure 1 , 2 As shown, the present invention provides a kind of multi-functional dough machine pulp extraction device, comprises pulp extraction roller 1, pressure roller 1-4, and is arranged on the pulp collecting frame 3 below pulp barrel 2; Said pulp extraction roller 1 The pressure rollers 1-4 are distributed on the upper and lower sides of the conveyor belt 5, and are arranged correspondingly. The middle part of the pulp extraction roller 1 is provided with a circular forming groove 1-1, and the two ends of the pulp extraction roller 1 are connected with pull-up The connecting rod 1-3; the slurry collection frame 3 includes two parallel sides and a baffle connected to the two parallel sides, and the slurry collection frame 3 is in sealing contact with the conveyor belt 5, and the two slurry collection frames 3 The side adjacent to the parallel side and pulp extracting roller 1 is an arc structure, and the bottom edge of the pulp collecting frame 3 is tightene...

Embodiment 2

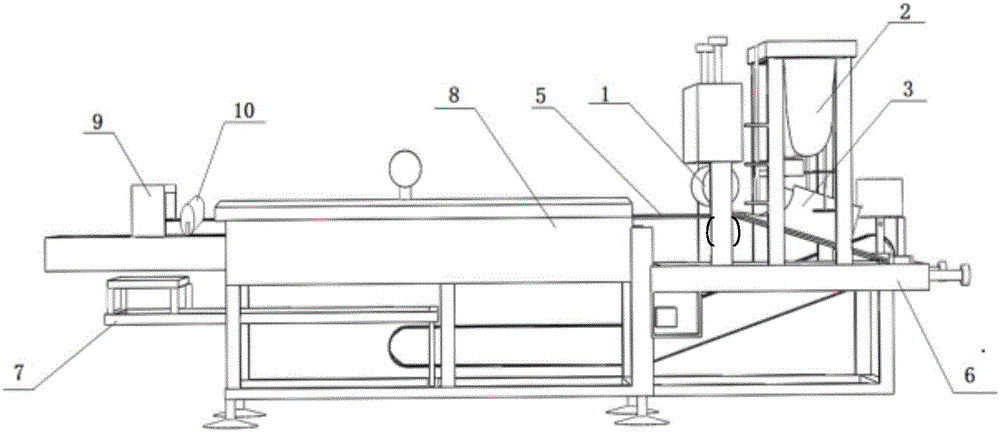

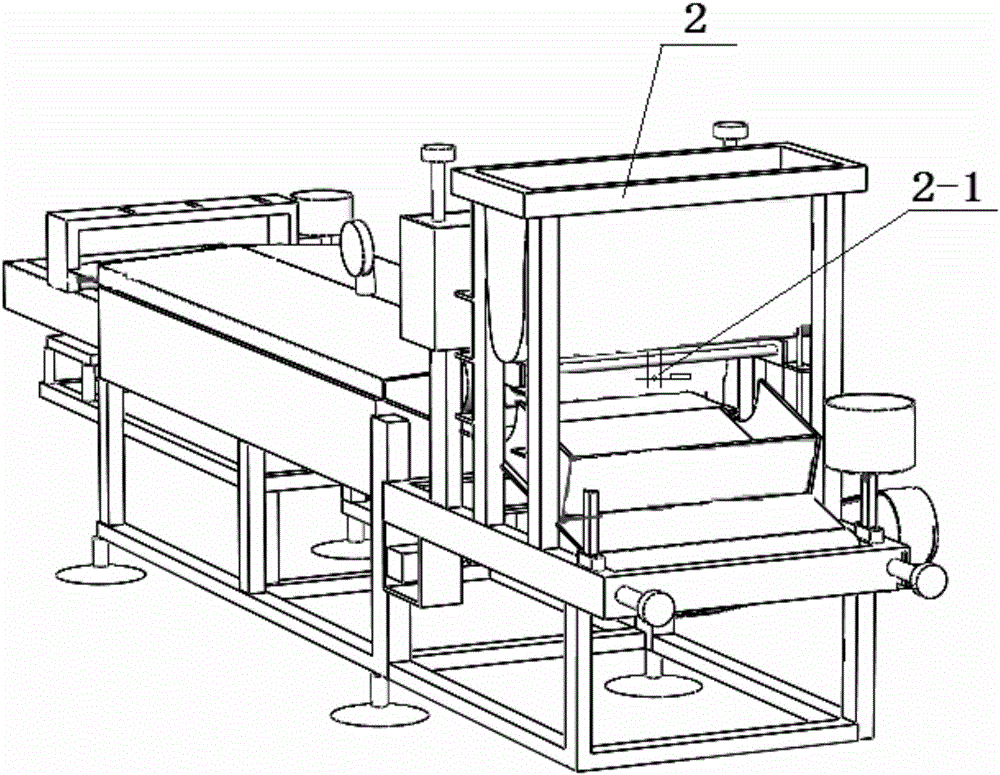

[0032] like figure 1 , 2 , shown in 3, the present invention provides a kind of multifunctional dough machine, comprise frame 6, conveying mechanism is installed on the described frame 6, one end of frame 6 is equipped with pulping bucket 2, from pulping bucket 2 one end A slurry extraction device, a curing box 8, and a cooling device 9 are installed in sequence, the conveyor belt 5 of the transmission mechanism passes through the aging box 8, and a material receiving device 7 is arranged below the end of the transmission mechanism; the slurry extraction device includes a slurry extraction Roller 1, pressure rollers 1-4, and pulp collecting frame 3 arranged under the pulp barrel 2; the pulp extraction roller 1 and pressure rollers 1-4 are located on the upper and lower sides of the conveyor belt 5, and are arranged correspondingly, The middle part of the pulp extraction roller 1 is provided with a circular forming groove 1-1, and the two ends of the pulp extraction roller 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com