Design method for heptafluoropropane gas fire-extinguishing system

A fire extinguishing system and heptafluoropropane technology are applied in the design field of heptafluoropropane gas fire extinguishing system, and can solve the problem that there is no calculation method for the time length and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

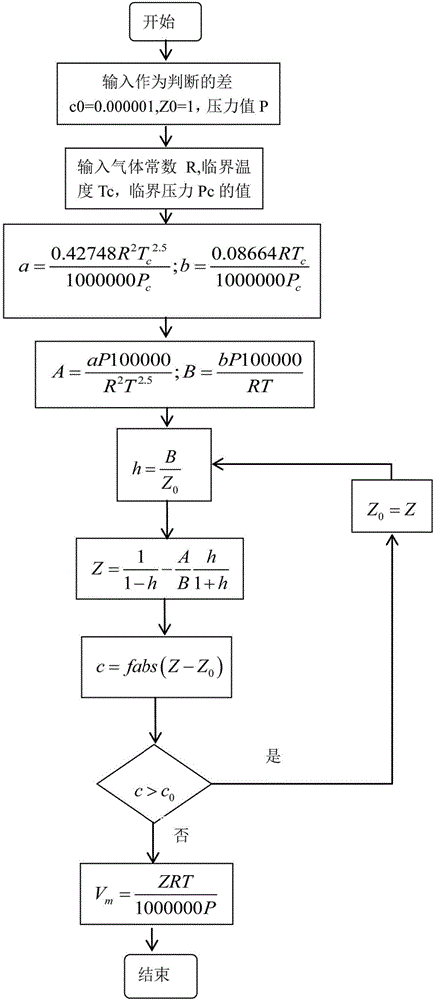

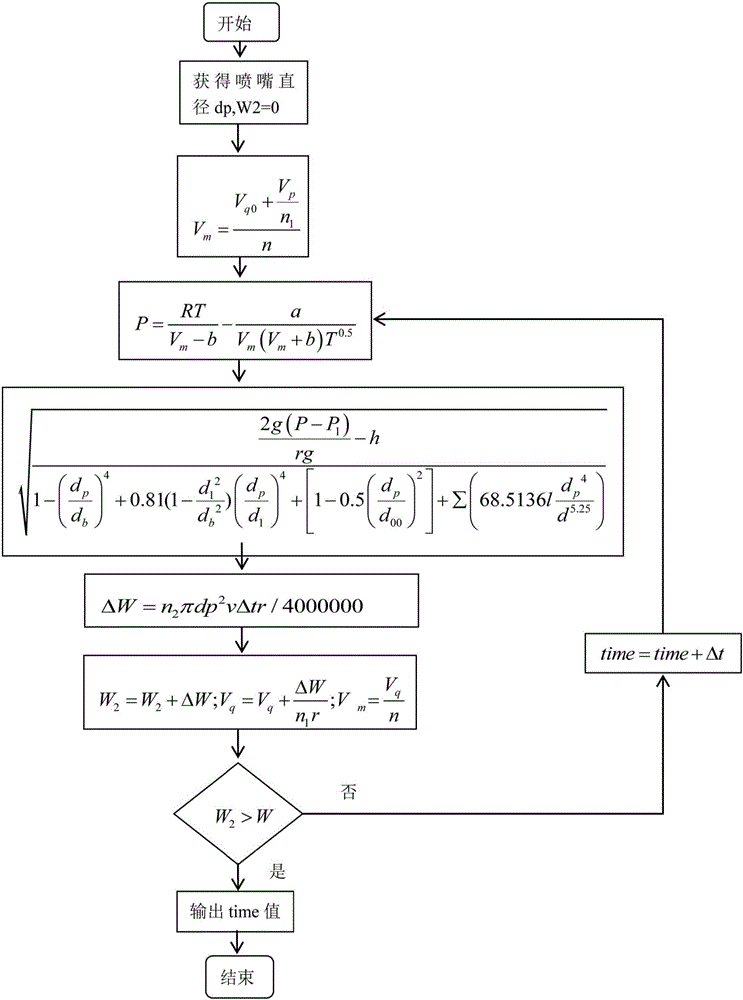

Method used

Image

Examples

Embodiment Construction

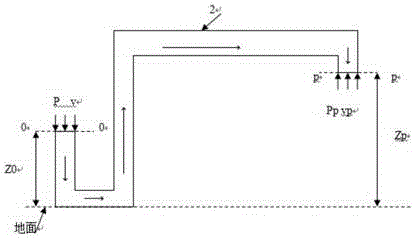

[0223] A design method of a heptafluoropropane gas fire extinguishing system, the fire extinguishing system is mainly composed of a high-pressure fire extinguishing agent storage bottle group 1, a fire extinguishing agent delivery pipe network 2, and a nozzle 3, and also includes a fire detection device, a pipeline control starting device and a starting bottle group, The spraying process is as follows: the fire detection device in the protection zone senses that the temperature on the spot rises or the concentration of smoke rises, and the signal is buried by the pipeline control starting device. After a period of delay, the circuit controls to open the bottle of the starting bottle group 1. Head valve, start the high-pressure nitrogen in the bottle group to open the container valve of the fire extinguishing agent storage bottle group 1, and the fire extinguishing agent flows through the riser 7 and the high-pressure hose 8 under the action of the high-pressure nitrogen in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com