Underwater docking mechanism with large redundancy

An underwater docking and redundancy technology, which is applied to underwater operation equipment, transportation and packaging, ships, etc., can solve the problems that there are not many, and the relative position between the main body and the target of underwater movement cannot be accurately determined or maintained. To achieve the effect of overcoming relative position and attitude errors and precise docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

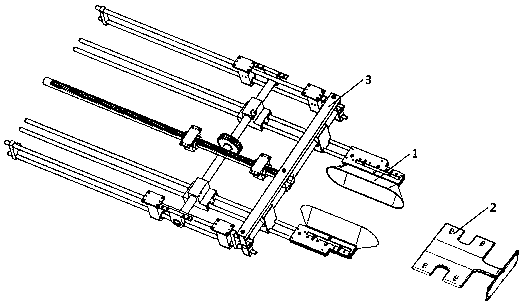

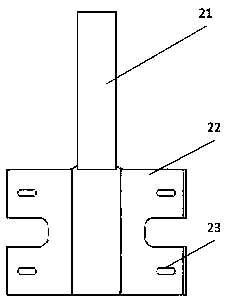

[0015] Such as figure 1 As shown, the underwater docking mechanism with large redundancy includes at least two docking sleeves 1 and a driving mechanism 3, the two docking sleeves 1 and the driving mechanism 3 are connected by connecting rods, and the driving mechanism 3 moves with the underwater moving body When approaching the docking handle 2, the driving mechanism 3 drives the openings of the two docking sleeves 1 to form a closed posture to capture the docking handle 2.

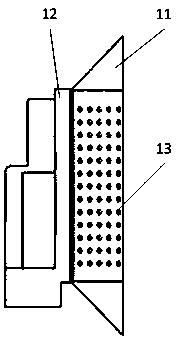

[0016] Such as figure 2 As shown, the butt joint sleeve 1 at least includes: a sleeve mouth 11, a sleeve seat 12, and a hydrophobic hole 13. The sleeve mouth 11 is in the form of an oblate bell mouth, with smooth arc structures at both ends, and distributed hydrophobic holes on the upper and lower slopes. hole 13 (see figure 1 ), the hydrophobic hole 13 facilitates the passage of water during underwater actions and reduces fluid resistance. The socket 11 is connected to the socket 12 by bolts, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com