A weft feeding mechanism of a rapier loom

A loom and weft feeding technology, which is applied in the field of weaving, can solve the problems of long time consumption and insufficient fabric quality, and achieve the effect of ensuring the strength of the weft thread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

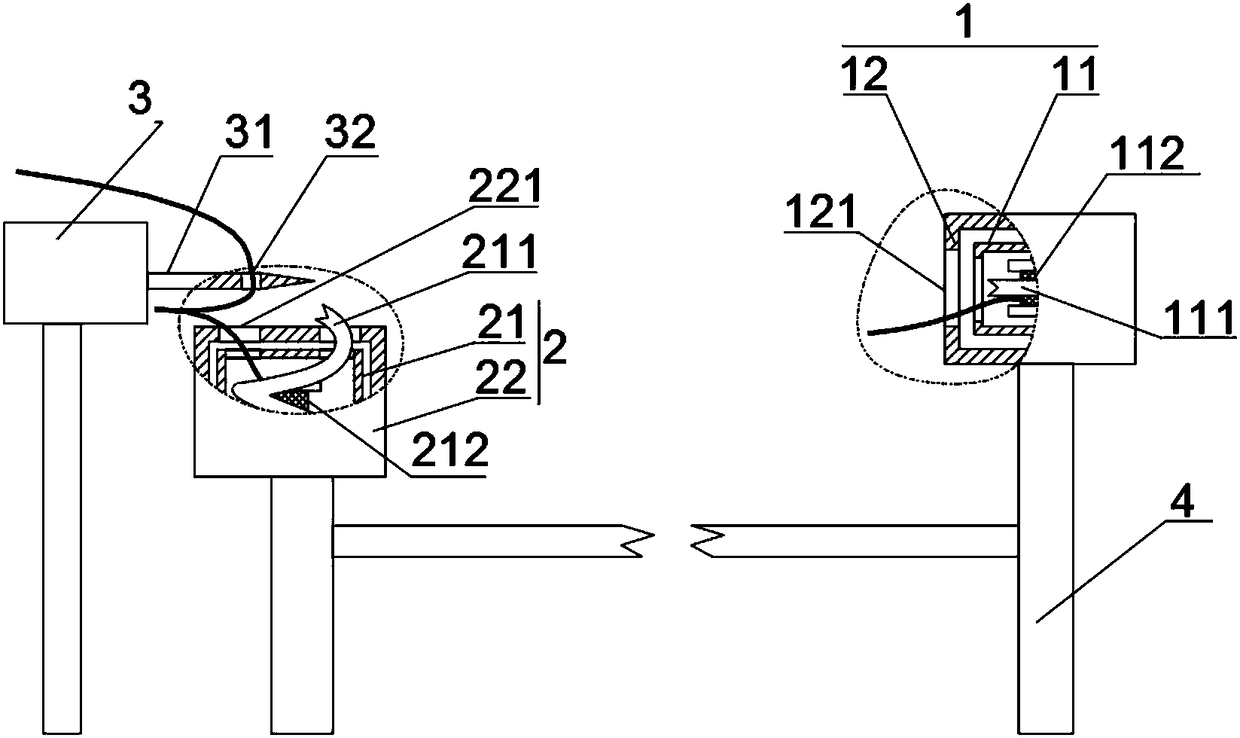

[0017] as follows figure 1 As shown, the present invention includes a weft feeding sword 3, a first weft receiving device 1, and a second weft receiving device 2; the first weft receiving device 1 and the second weft receiving device 2 are installed on the loom frame 4 The two ends are corresponding; the weft feeding sword is installed on the frame, and is located between the first weft receiving device 1 and the second weft receiving device 2 , and corresponds to the first weft receiving device 1 . By returning the weft sending sword 3 after contacting the first weft receiving device 1, the purpose of sending weft and drawing two weft threads at one time by the weft sending sword 3 is realized.

[0018] As an improvement of this embodiment, a round hole 32 is provided on the sword head of the weft feeding sword; the sword head of the weft feeding sword is pointed. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com