Excessive vibration preventing roller washing machine

A drum washing machine and washing machine technology, applied in the field of washing machines, can solve problems such as shortage, insufficient precision of anti-vibration technology of washing machines, etc., and achieve the effect of avoiding excessive vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described now in conjunction with accompanying drawing.

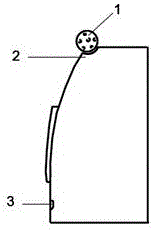

[0030] An anti-excessive-vibration drum washing machine, the anti-excessive-vibration drum washing machine has a washing machine body, the washing machine body has a shell, and an outer tub with an open front end arranged transversely is arranged in the outer tub, and the outer tub is rotatably arranged There is a washing drum with a front opening, and the casing has a door for closing the front opening of the outer tub, and a control panel for controlling the operation of the anti-excessive vibration drum washing machine is provided on the upper part of the casing; The body also has a drainpipe connected to the outer tub, and it is characterized in that the anti-excessive vibration drum washing machine has a vibration monitoring component.

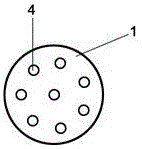

[0031] Preferably, the vibration monitoring component has a plurality of shelving slots 2 arranged on the housing, and a shutdown remot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com