Modular box type plate-girder structure and bridge body erection method based on box type plate-girder structure

A box-type slab and beam structure technology, applied in the field of steel bridge structure, can solve the problems of many Bailey bridge components, low efficiency, slow construction speed of manpower erection, etc., and achieve the effect of fast erection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

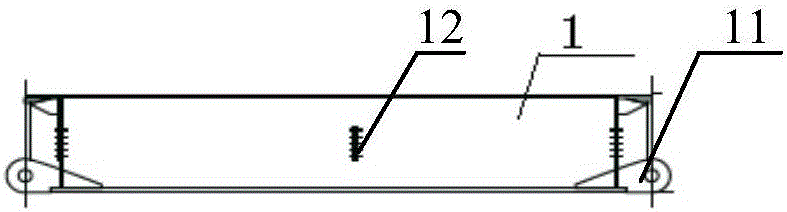

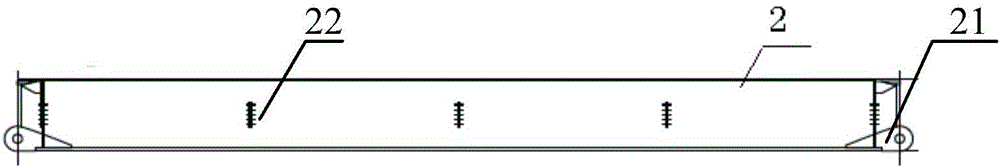

[0021] Embodiment 1: Referring to the accompanying drawings, a modular box-type plate girder structure includes: a main girder, a beam 5, and a longitudinal girder 6 with a bridge deck;

[0022] The main girder is a box girder section, with a set of lugs 11, 21 for connecting pins to other girders at the lower part of each end, and a plurality of stiffening webs 12, 22 on both sides, and the stiffening webs 12, 22 are provided with bolt holes , used to connect the crossbeam 5 by friction-type high-strength bolts, and the main beam is manufactured by welding;

[0023] The crossbeam 5 is a rolled channel steel, with bolt holes matching the bolt holes on the stiffening webs 12 and 22 at both ends of the elevation, and bolt holes for connecting the longitudinal beam 6 with the bridge deck on the top surface;

[0024] The longitudinal girder 6 with the bridge deck includes: a steel bridge deck and a plurality of I-beams 61 fixedly connected under the steel bridge deck. The I-beams ...

Embodiment 2

[0026] Embodiment 2: On the basis of the modular box-shaped plate girder structure of Embodiment 1, add: railing column 3, railing crosspiece 4, railing column 7 with crossbeam, sidewalk bridge deck 8, sidewalk railing 9;

[0027] The railing column 3 is a rolled section steel, and its lower part is provided with bolt holes matching the bolt holes on the stiffening webs 12, 22 for connecting the main beam; its inner side is provided with bolt holes for connecting the railing crosspiece 4;

[0028] The railing crosspiece 4 is a rolled section steel, which is provided with bolt holes for connecting the railing column 3;

[0029] The railing column 7 with crossbeam is a rolled section steel, and its lower part is provided with bolt holes matching the bolt holes on the stiffening webs 12, 22 for connecting the main beam; its inner side is provided with bolts for connecting the railing crosspiece 4 Hole, the horizontal crossbeam 71 that its outer side is fixedly connected triangula...

Embodiment 3

[0032] Embodiment 3: the bridge body erection method based on the modular box-type slab girder structure, it uses the modular box-type slab girder structure as described in embodiment 1, comprises the following steps:

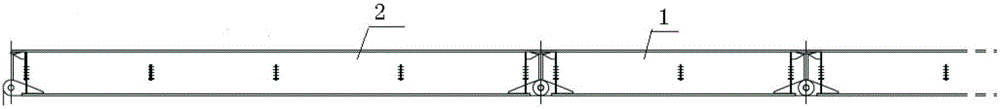

[0033] A. Select an appropriate number of short-span standard section main girders 1 and long-span standard section main girders 2 according to the length of the bridge body and the number of lanes to be erected, and connect them into several main girder combinations through pins; Figure 5 As shown, when erecting a single lane, two main girders are required; Figure 6 As shown, the combination of three main girders is required when erecting a double lane; Figure 7 As shown, when erecting three lanes, four main girders are required;

[0034] B. Place the connected main girder combination on the bridge support that has been installed by means of crane hoisting or horizontal push;

[0035] C. Between the adjacent main girder combinations in place, use friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com