Damper for lifting rod of automobile trunk

A trunk and lifting rod technology, which is applied in the field of dampers, can solve the problems that the lifting device cannot support the trunk door, the opening and closing force of the door is unreasonable, and the trunk is inconvenient to use, so as to achieve a compact internal structure design and open It is convenient and fast to close and close, and the overall structure design is reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical means and effects of the present invention to achieve the predetermined purpose, the specific implementation of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

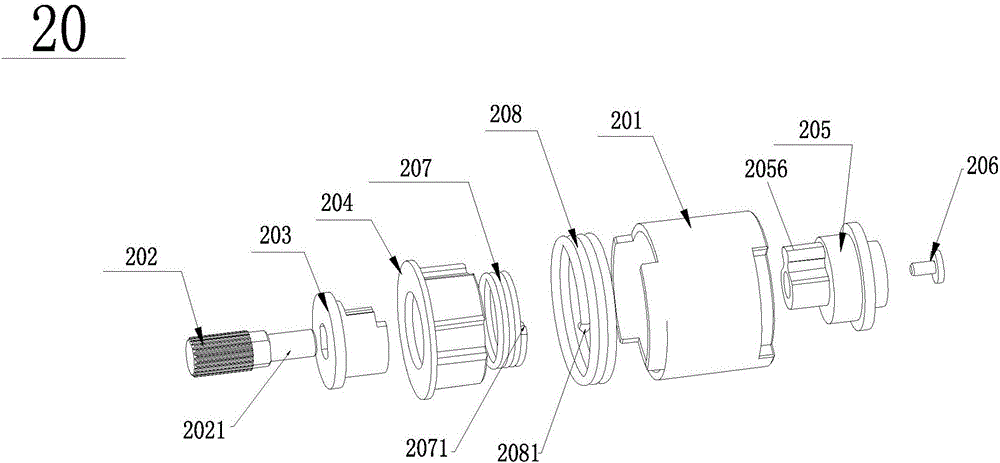

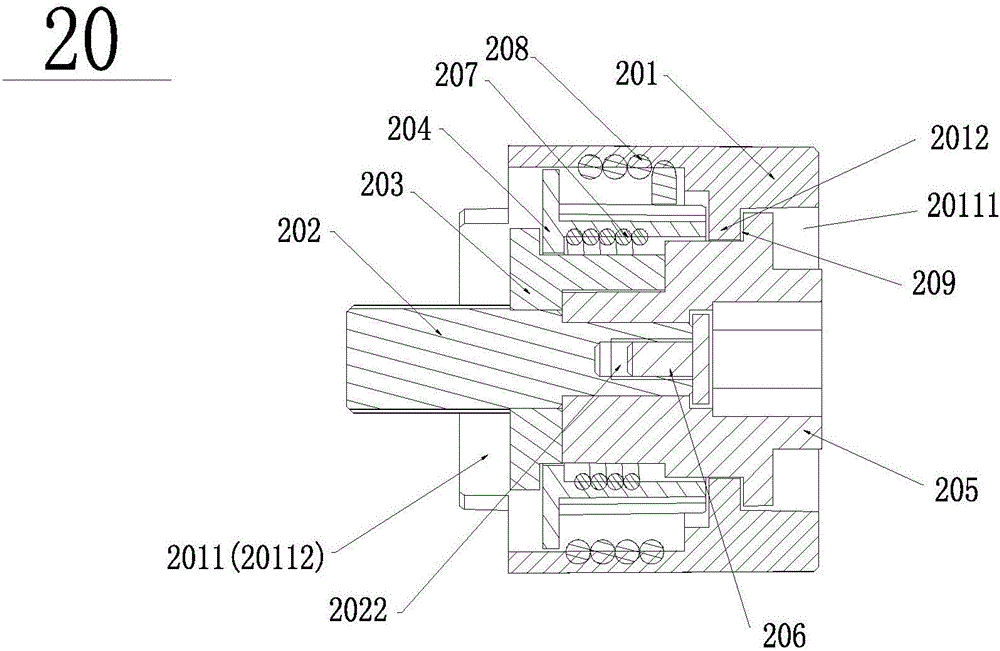

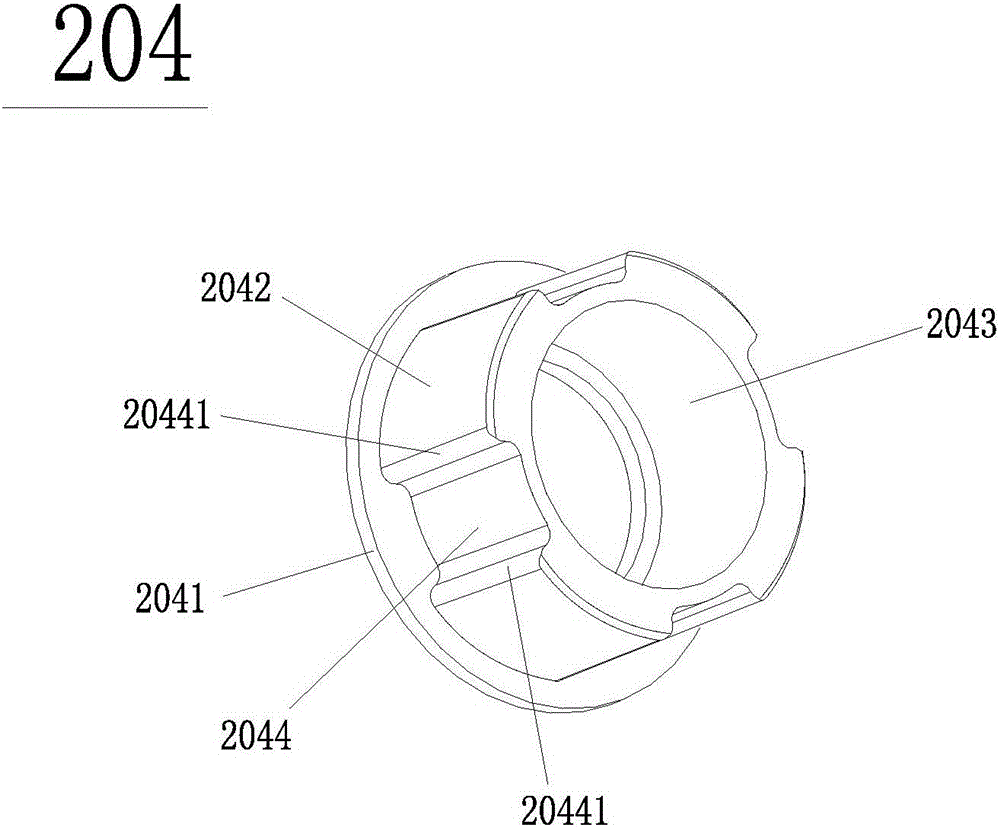

[0023] Please refer to Figure 1 to Figure 5 , The embodiment of the present invention provides a damper 20 for an automobile trunk lifting rod, including a housing 201 in which an input shaft 202, an inner core 203, an outer core 204, and an output shaft 205 are respectively arranged, wherein The upper end of the inner core 203 is inserted into the outer core 204, the lower end of the output shaft 205 is inserted into the outer core 204 and the inner core 203 in turn, the upper end of the input shaft 202 is inserted into the inner core 203 and the output shaft 205 in turn, the upper end of the input shaft 202 and The lower ends of the output shaft 205 are connected by a screw 206, and an inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com