Heat preservation strengthening member applied to building window in severe cold area

A technology for strengthening components and areas, applied in building components, building structures, buildings, etc., can solve the problems of inconvenient disassembly and assembly, complex thermal insulation structure, etc., and achieve the effect of increasing service life and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

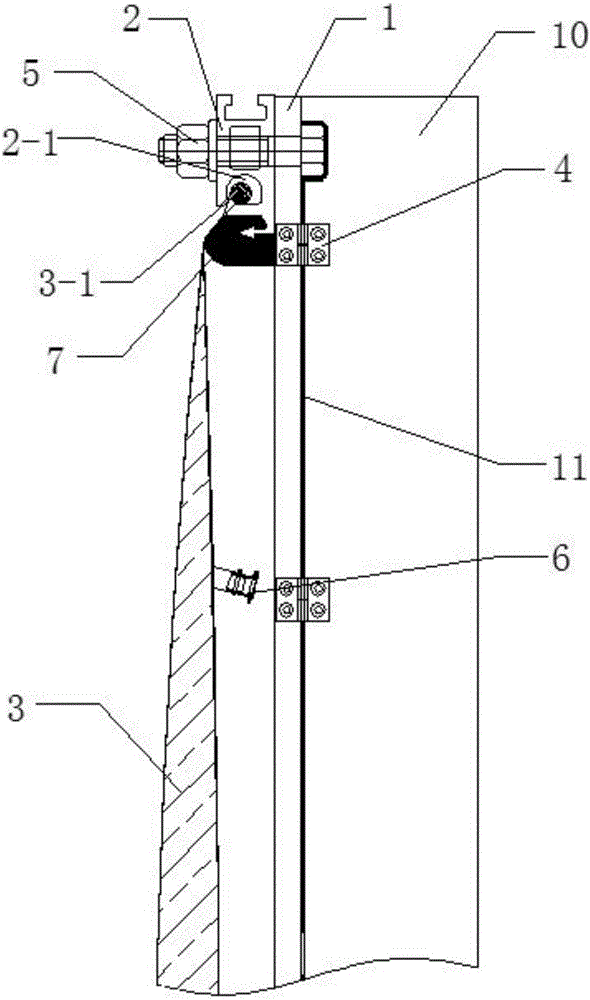

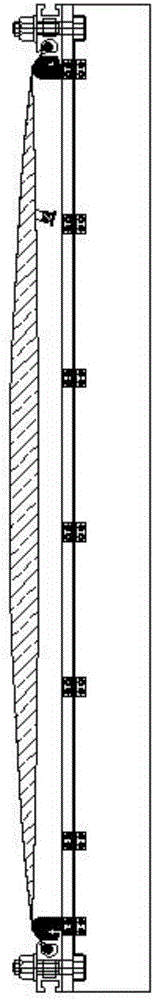

[0012] Specific Embodiment 1: This embodiment is applied to building windows in severe cold areas. The thermal insulation reinforcement components include a backing plate frame 1, an ETFE air pillow 3 and two air pillow box profiles 2. The backing plate frame 1 is arranged outside the window frame 10 through a hinge 4. On the window frame surface, two air pillow box profiles 2 are respectively arranged on the upper frame and the lower frame of the backing plate frame 1 through fixing bolts 5, and the upper pillow edge and the lower pillow edge of the ETFE air pillow 3 are respectively provided with pillow shafts 3-1 , the air pillow box profile 2 has a cavity 2-1 for accommodating the air pillow shaft 3-1, and the pillow shaft 3-1 of the ETFE air pillow 3 is located in the cavity 2 for accommodating the air pillow shaft 3-1 in the air pillow box profile 2 In -1, the ETFE air pillow 3 is hung on the front part of the outer window.

[0013] The ETFE air pillow described in this ...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the thermal insulation reinforcement component applied to building windows in severe cold regions also includes an inflatable device.

[0020] In this embodiment, gas is filled into the ETFE air pillow through an inflator.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the ETFE air pillow 3 is filled with air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com