Power connector, two-body all-terrain vehicle

An all-terrain vehicle and double-body technology, which is applied to fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve problems such as easy damage, leakage, and easy loosening of connecting pipe joints, so as to avoid The effect of the leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

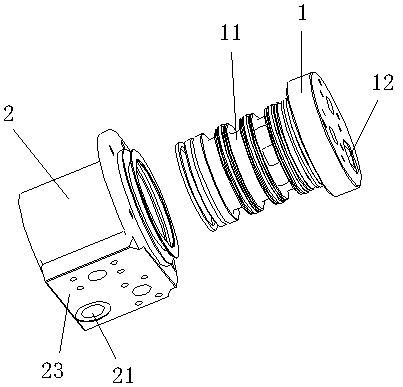

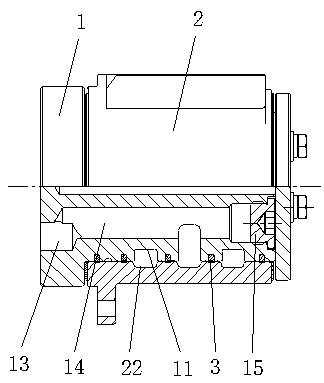

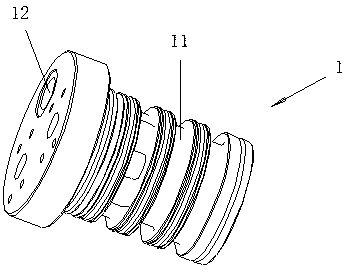

[0035] Please refer to figure 1 and figure 2 , figure 1 An exploded view of a specific embodiment of the power connector of the dual-body all-terrain vehicle provided by the present invention; figure 2 for figure 1 Half cutaway view of the power connector shown.

[0036] In a specific embodiment, the present invention provides a power connector, including a rotating inner core 1 and a fixed housing 2; three annular oil passages 11 are provided on the circumference of the rotating inner core 1, and three annular oil passages 11 are provided on one end of the rotating inner core 1. The end face oil port 12, the three end face oil ports 12 are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com