Small compression spring static pressure method and device thereof

A compression spring, small technology, applied in the direction of manufacturing springs, other household appliances, household appliances, etc. from wires, can solve the problems of low production efficiency, spring torsion deformation, and complicated static pressure operation of small compression springs, and achieves high work efficiency. The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

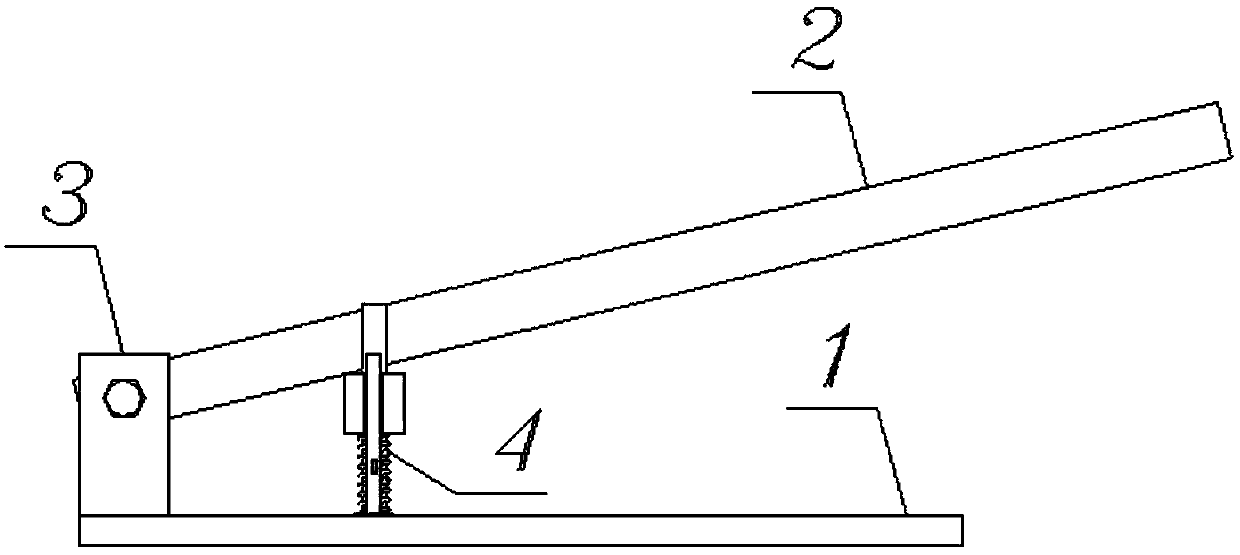

[0022] figure 1 It is a structural schematic diagram of a small-sized compression spring static pressure method and its device according to the present invention. The device includes:

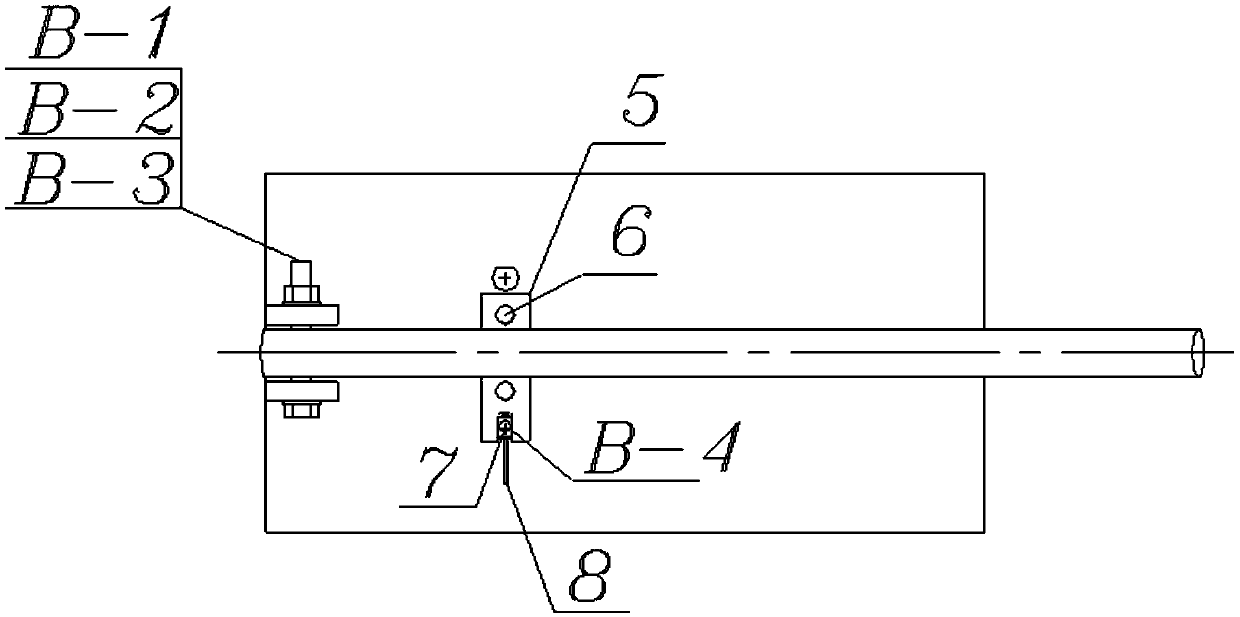

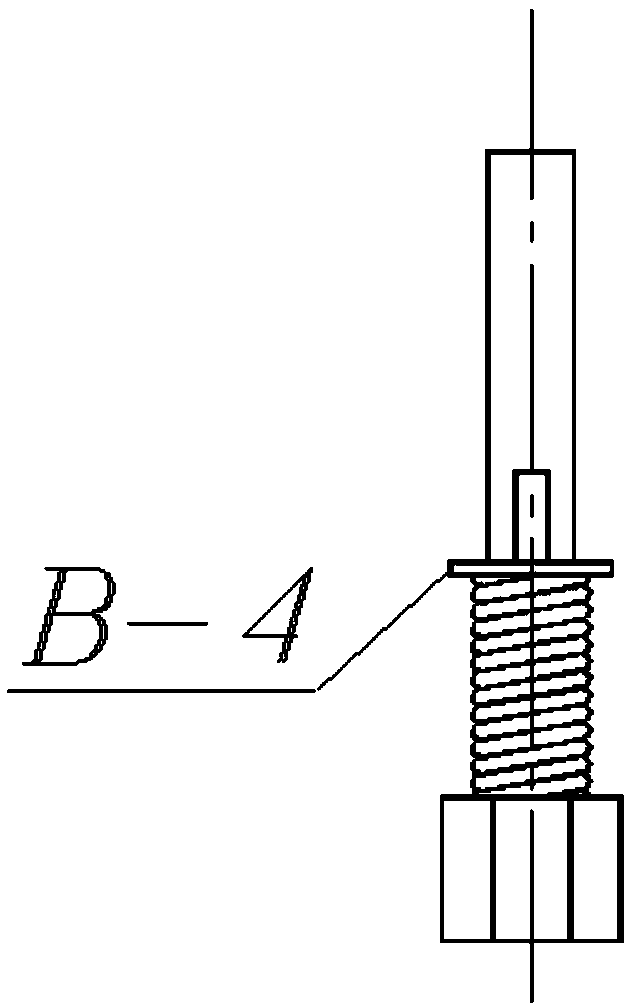

[0023] Rectangular block base plate 1 is used to install spring compression parts, including rectangular block support 3, cylindrical guide rod 6, support 3 is welded to base plate 1, guide rod 6 and base plate 1 are connected by thread, replaceable, guide rod 6 Two cylindrical positioning grooves with plane notches are symmetrically distributed on both sides.

[0024] The compression rod 2 is a round rod structure, connected with the support 3 through the standard hexagon head bolts, flat washers, hexagon nuts B-1, B-2, B-3, the compression rod 2 takes the hexagon head bolt B-1 as the axis, Rotational movement is possible.

[0025] The strong pressing block 5 is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com