Anti-CO poisoning rotary chimney head based on flow rate differential pressure

A technology with poor flow velocity and chimney head, applied in the field of anti-CO poisoning rotary chimney head, can solve the problems of single function, no anti-CO poisoning, poor rainproof performance, etc., and achieve the effect of simple principle structure, prevention of CO poisoning, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

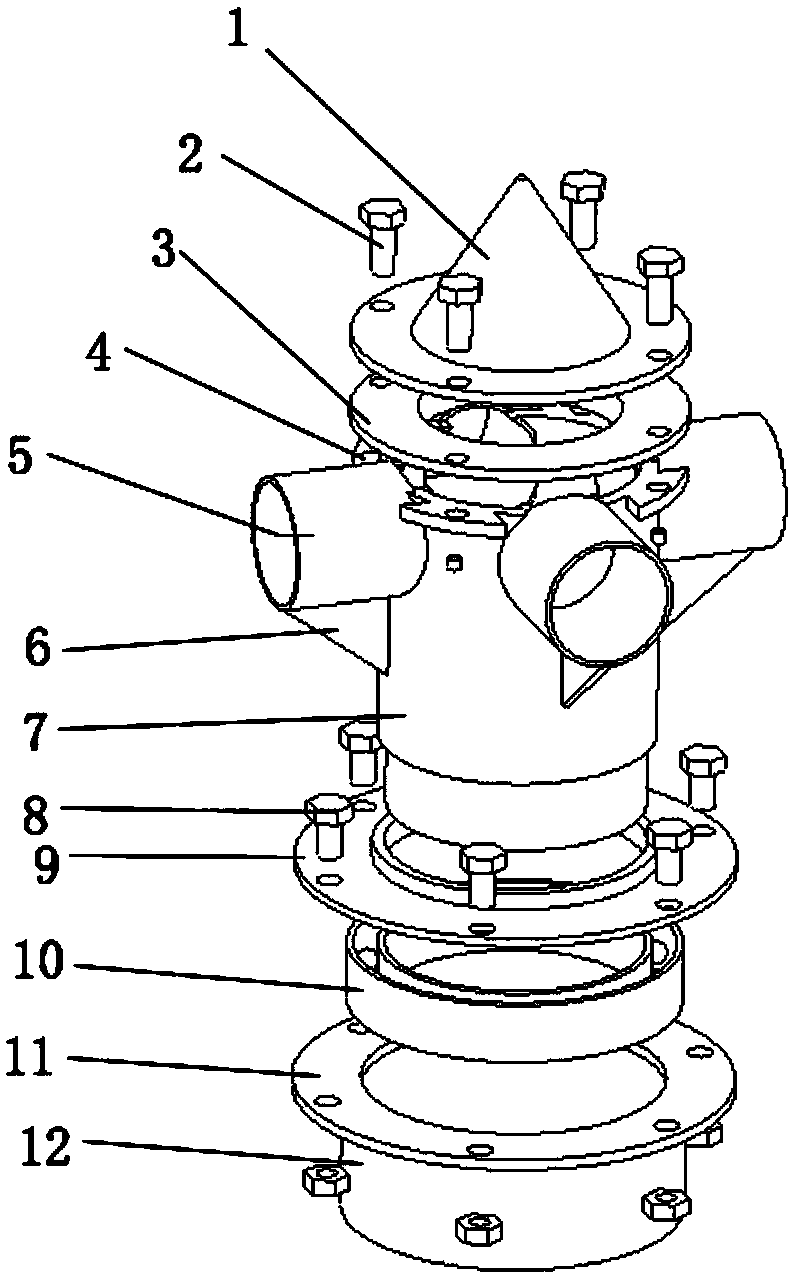

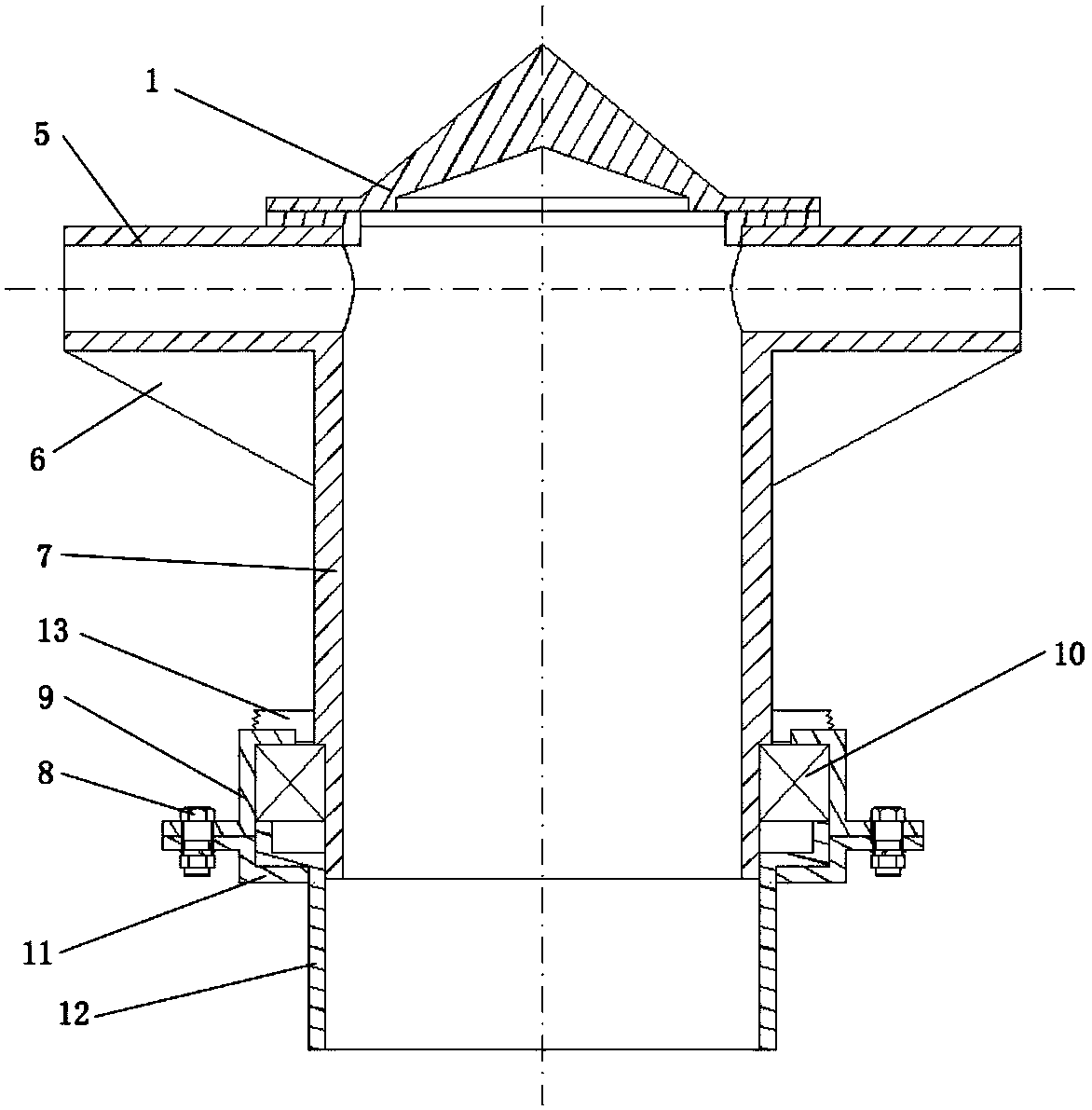

[0020] see figure 1 , 2 The anti-CO poisoning rotary chimney head based on the flow rate differential pressure of the present invention includes a top cover 1, and the lower end of the top cover 1 is fixed along the first bolt group 2 through the sealing ring 3 and the upper extension end 4 of the main cylinder 7; Ventilation pipe 5 is welded between the four extending ends of cylinder 7; support plate 6 is welded at the lower end of ventilation pipe 5; The upper part passes through the upper fixed plate 9, and the outer side of the barrel connects with the inner ring of the bearing 10, and then passes through the lower fixed plate 11 and fits in the slot of the installation cylinder 12; the bearing 10 is set on the upper fixed plate 9, and the outer ring is engaged with the The upper end of the lower fixed plate 11 is in the groove; the upper fixed plate 9 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com