Assembling structure for decoration strip and handle of refrigerator door frame

A technology for assembling structures and decorative strips, applied in door/window fittings, wing handles, building structures, etc., can solve the problems of obvious touch, prolapse, and low product quality, and achieve the effect of rich line sense and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

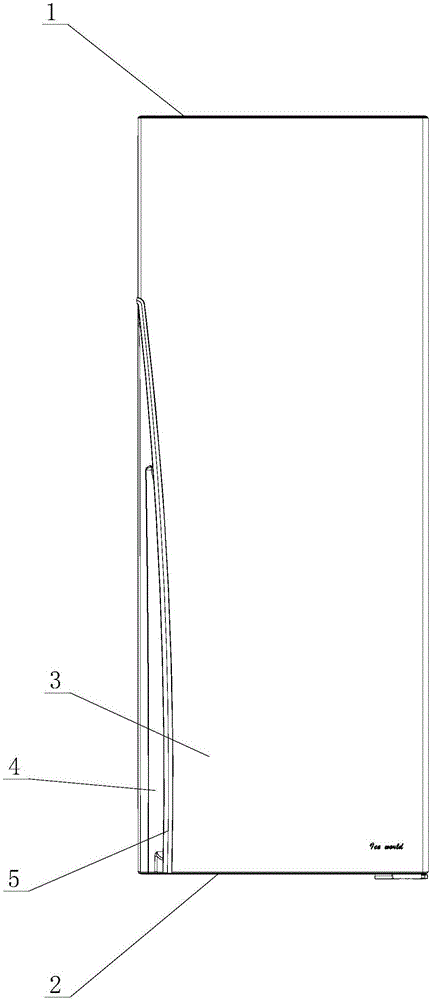

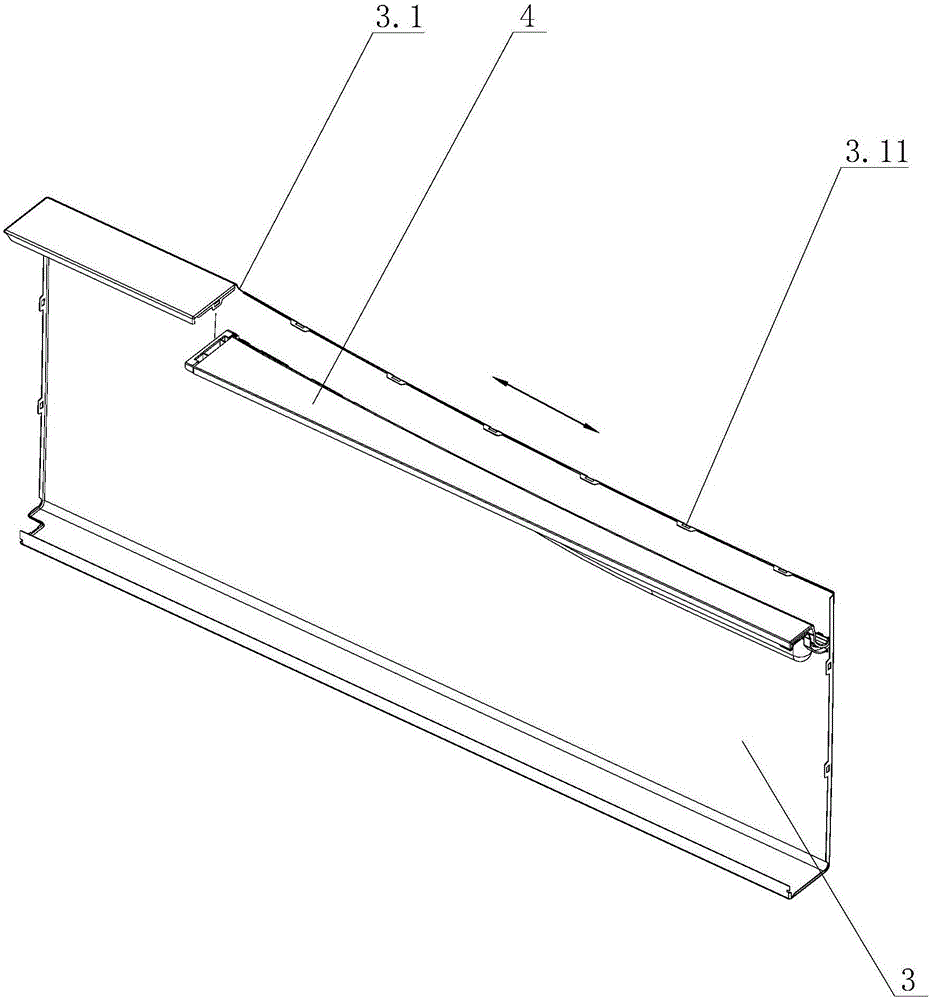

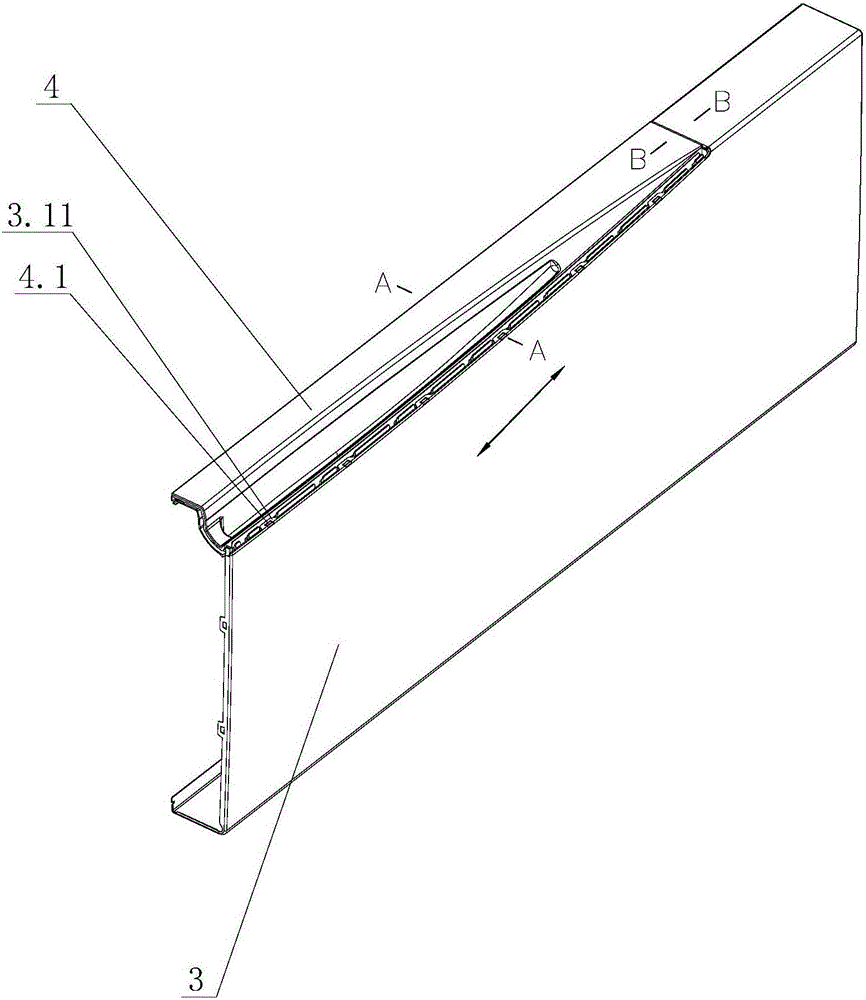

[0028] see Figure 1-Figure 9 , an assembly structure of a refrigerator door frame decorative strip and a handle, comprising an upper end cover 1, a lower end cover 2 and a door panel 3; the door panel 3 is provided with a handle 4 and a decorative strip 5, and the door panel 3 is provided with an assembly position 3.1; the assembly position 3.1 is matched with the handle 4; the decorative strip 5 is provided with an assembly groove 5.1; the assembly groove 5.1 is inserted into the handle 4 and the door panel 3.

[0029] Furthermore, the assembly position 3.1 is a notch matching the shape of the handle 4; the handle 4 is snapped into the assembly position 3.1. There are card positions 3.11 evenly distributed vertically in the assembly position 3.1; a buckle 4.1 corresponding to the card position 3.11 is provided on the side of the handle 4 in contact w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com