Thermal circuit model-based method for obtaining coiling hot point temperature of transformer

A technology of hot spot temperature and thermal circuit model, which is applied in the field of electric power equipment, can solve problems such as doubling of insulation aging rate, failure to consider, and failure of effective use of equipment, etc., to achieve the effect of accurate temperature value of winding hot spot and overcome the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

[0042] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0043] The present invention will be further described below with reference to the drawings and specific embodiments, but it is not a limitation of the present invention.

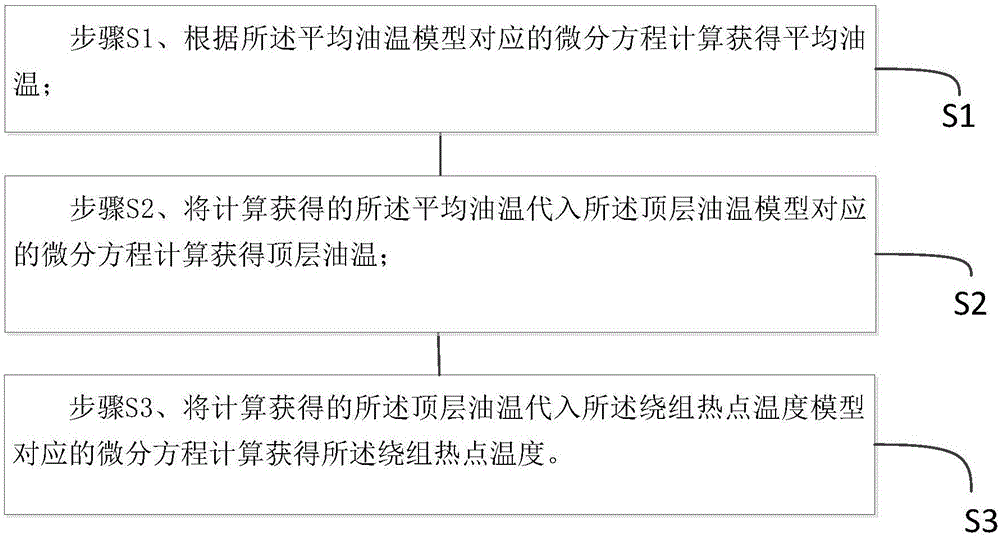

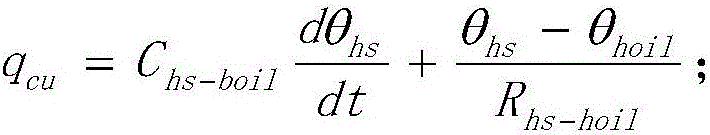

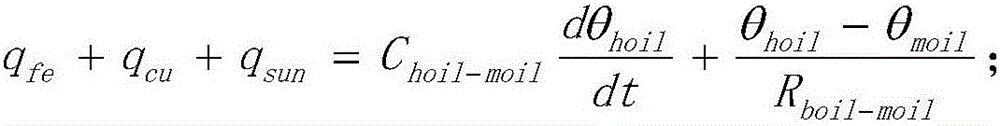

[0044] The technical scheme of the present invention includes a method for obtaining the winding hot spot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap