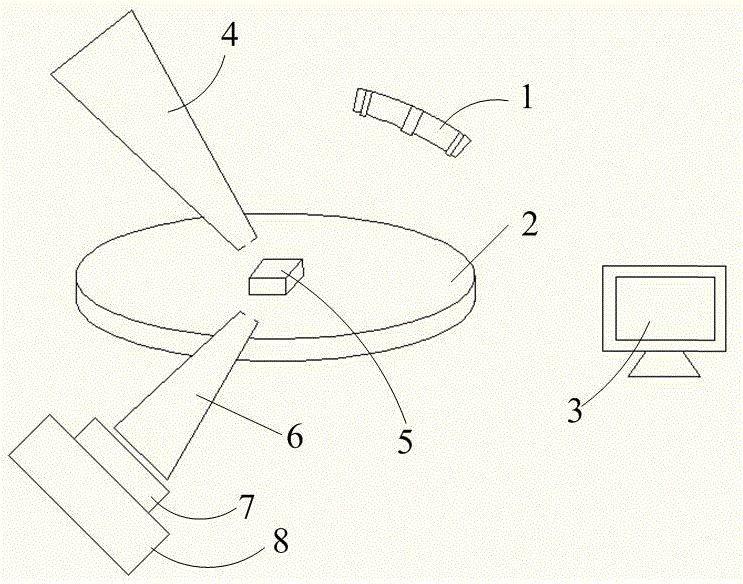

Three-dimensional calibrating measurement device for neutron diffraction stress analysis

A technology for stress analysis and measuring devices, applied in measuring devices, using wave/particle radiation for material analysis, analyzing materials, etc., can solve problems such as errors and achieve the effect of low space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

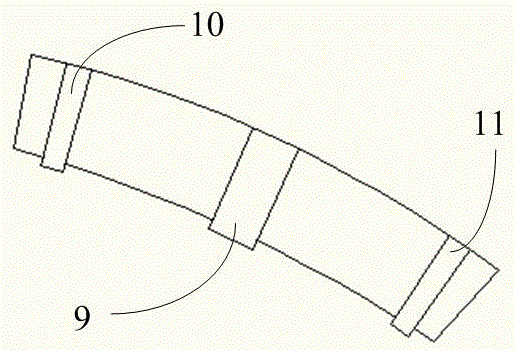

[0037] The working process of the three-dimensional calibration measurement device for neutron diffraction stress analysis of the present invention is as follows: firstly, the three-dimensional scanner is used to cooperate with the multi-degree-of-freedom movement of the sample stage, and the appearance information of the sample placed on the sample stage is collected into the computer , obtain the scanned image, and establish the three-dimensional model of the sample. Then perform meshing processing on the 3D model, and assign a unique identifier to each mesh. Next, select a target grid on the three-dimensional model by manual or automatic mode, and control the movement of the sample stage with the help of a motion control program installed in the computer, so that the incident slit is aligned with the target grid, and at the same time, the diffraction slit, collimation The collimator and neutron detector move to the position of the Bragg angle, turn on the neutron beam switch ...

Embodiment 2

[0041] The embodiment of this embodiment is basically the same as that of the embodiment 1, the main difference is that the sample 2, the rectangle 2, different equipment and equipment structure, can obtain the precision 2 within 100 μm.

Embodiment 3

[0043] The embodiment of this embodiment is basically the same as that of the embodiment 1, the main difference is that the sample 2, the rectangle 2, different equipment and equipment structure, can obtain the precision 2 within 100 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com