Containing tool dedicated for optical fiber of transformer substation

A technology for optical fibers and substations, applied in the directions of light guides, optics, optical components, etc., it can solve the problems of falling to the ground, affecting the work progress, and being easily damaged, reducing the bending angle, improving the convenience, and avoiding the effect of breaking free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

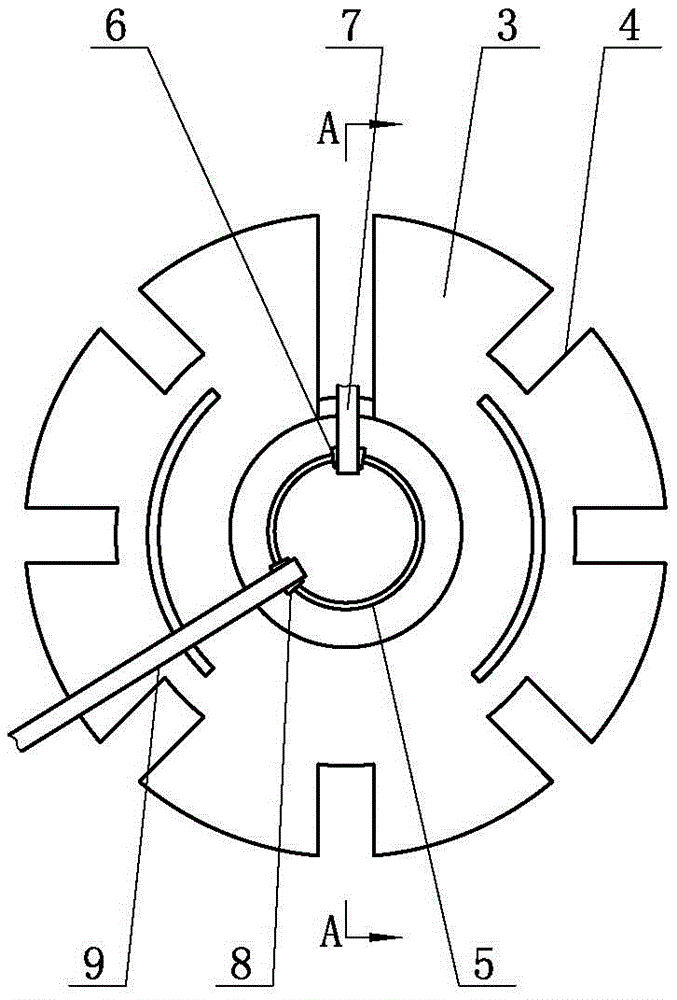

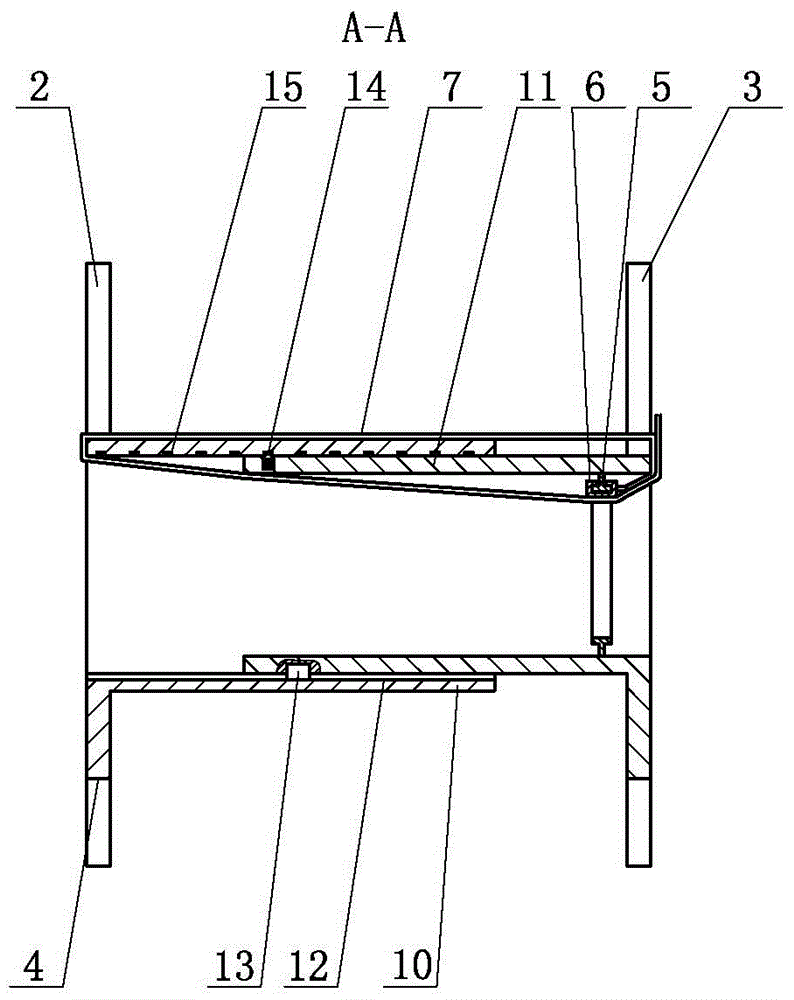

[0008] A special storage tool for substation optical fiber according to the present invention includes a cylindrical roller, the outer peripheral walls of the two ends of the cylindrical roller are respectively provided with a first baffle 2 and a second baffle 3, the first baffle 2 and the second baffle A plurality of notches 4 are provided in the 3 circles, and each notch 4 is evenly distributed along the 3 circles of the first baffle 2 or the second baffle, and the positions of the notches 4 on the first baffle 2 and the notches 4 on the second baffle 3 are One-to-one correspondence, the inner wall of the cylinder roller is provided with a ring guide rail 5, and the first slider 6 is installed on the ring guide rail 5, the first slider 6 can move along the ring guide rail 5, and the first slider 6 is connected to one end of the first strapping belt 7 , the front and back sides of the first strapping 7 are respectively provided with a hook surface and a suede surface of a vel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com