New core make-up tank to mitigate sloshing effects

A core make-up tank, a new type of technology, applied in the directions of reactors, greenhouse gas reduction, climate sustainability, etc., can solve problems such as jeopardizing the structural integrity of the core make-up tank, inaccurate reflection of water level signals, and influence of water level measurement signals, etc. It is easy to implement and popularize, reduce the inaccuracy of liquid level measurement, and suppress the sloshing phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

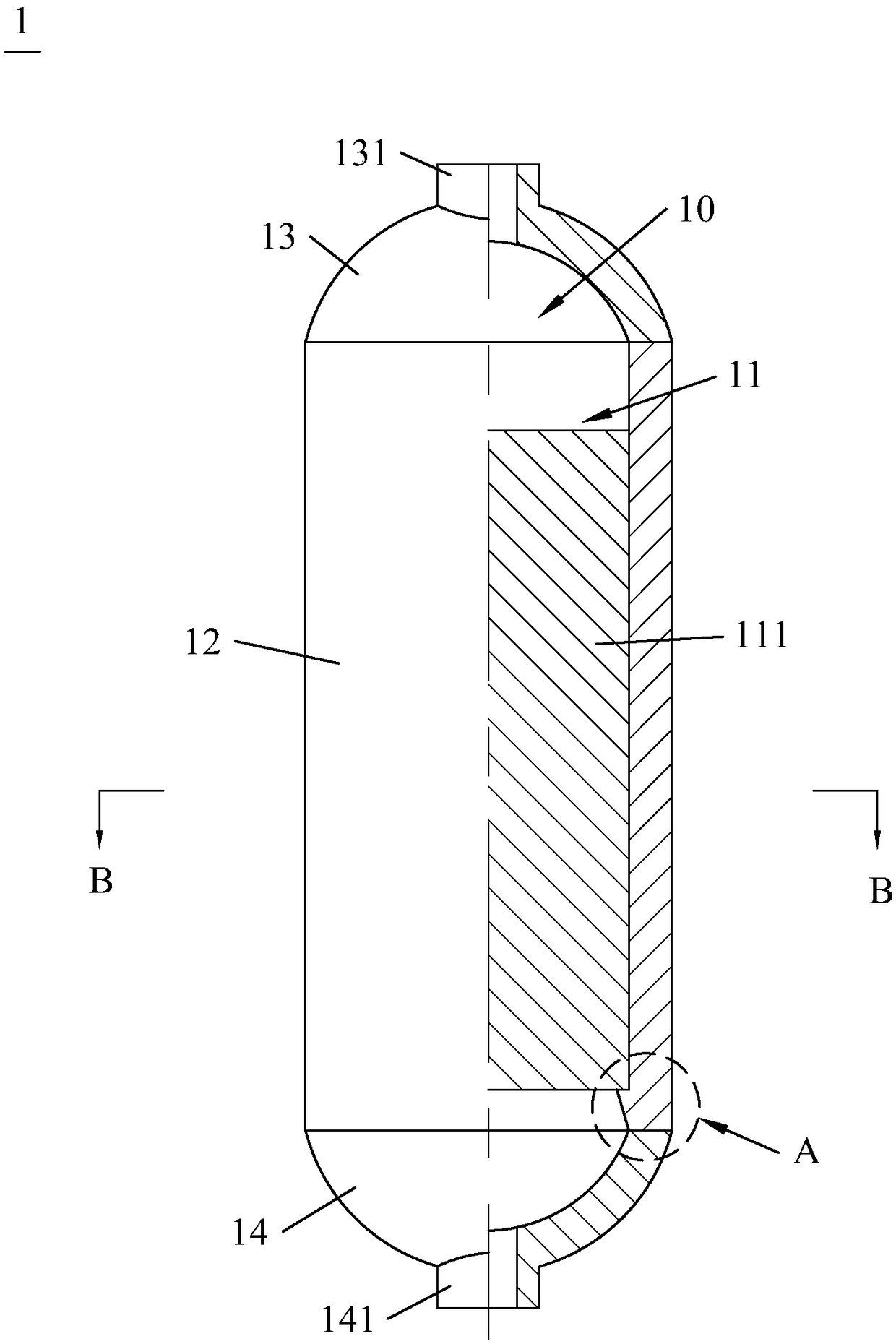

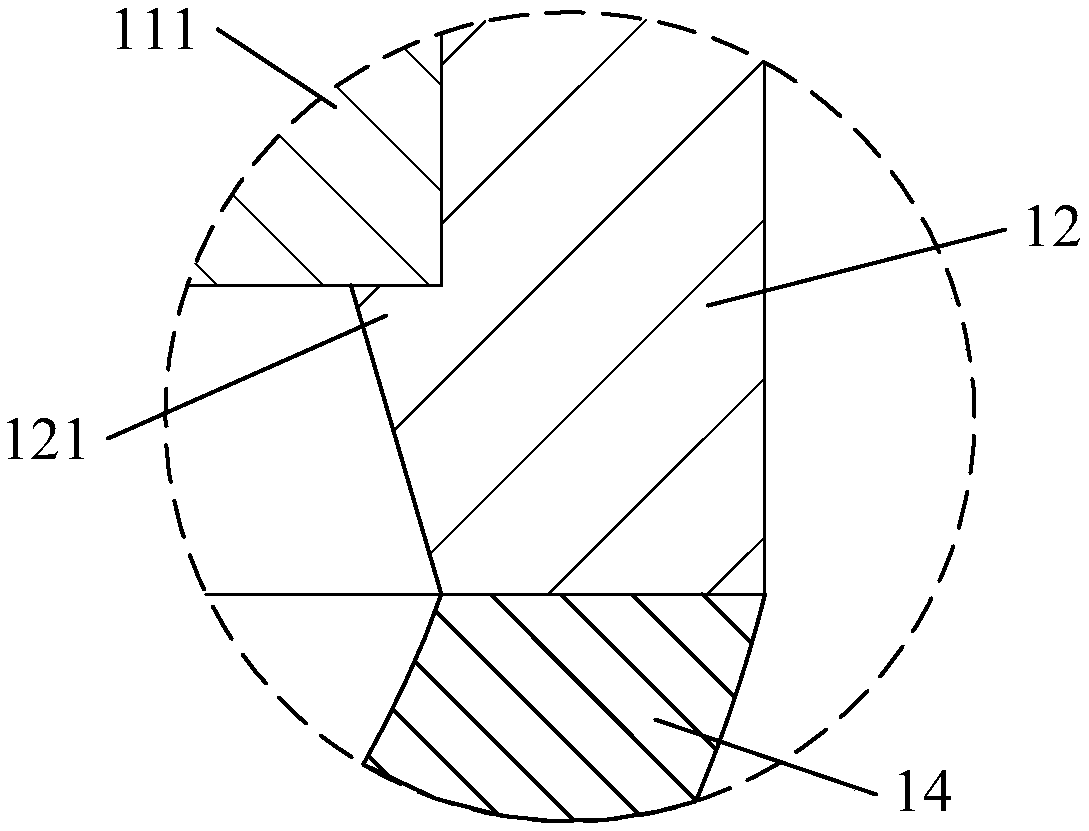

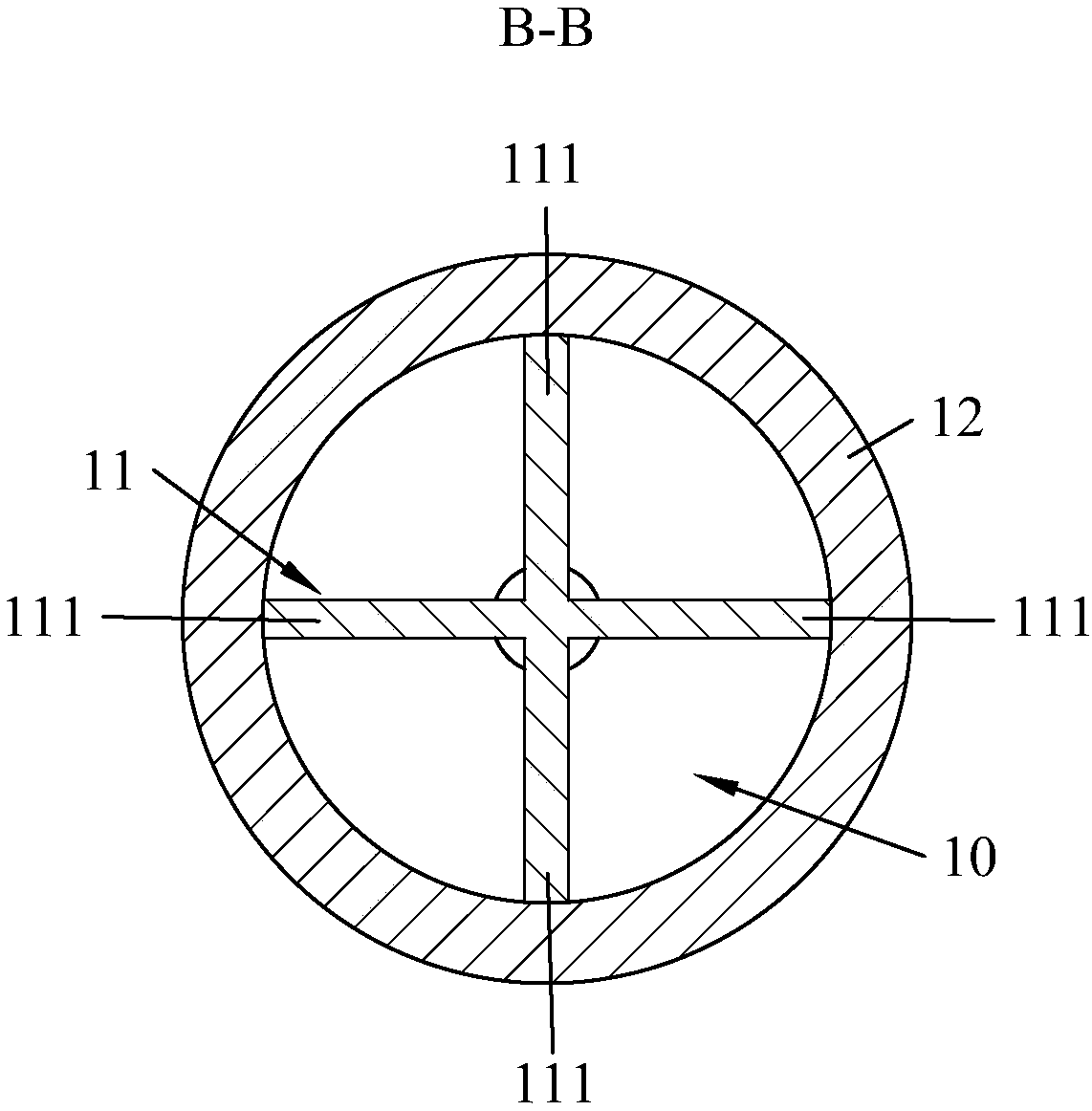

[0017] combine Figure 1 to Figure 3 As shown, the present invention provides a novel core makeup water tank 1 that can reduce the impact of sloshing, including a tank with a cavity 10 inside and a partition 11 arranged in the tank, and the partition 11 divides the cavity inside the tank. The middle section of the cavity 10 is divided into several parts extending along the height direction of the box body, while the upper part and the lower part of the cavity 10 are not separated by the partition 11 . Each part separated by the partition 11 is a slender space with a relatively small diameter and height. In such a space, sloshing is not easy to occur on site, that is, the setting of the partition 11 can effectively suppress sloshing in the new core make-up water tank 1 Phenomenon.

[0018] Specifically, the box body includes a hollow cylindrical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com