Key switch having good balance

A balanced, key-pressing technology, applied in electrical switches, electrical components, circuits, etc., can solve problems such as unsmooth use, affecting normal use, and pressing feeling, so as to improve pressing balance and pressing stability, and enhance pressing. Feel, with the effect of lengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

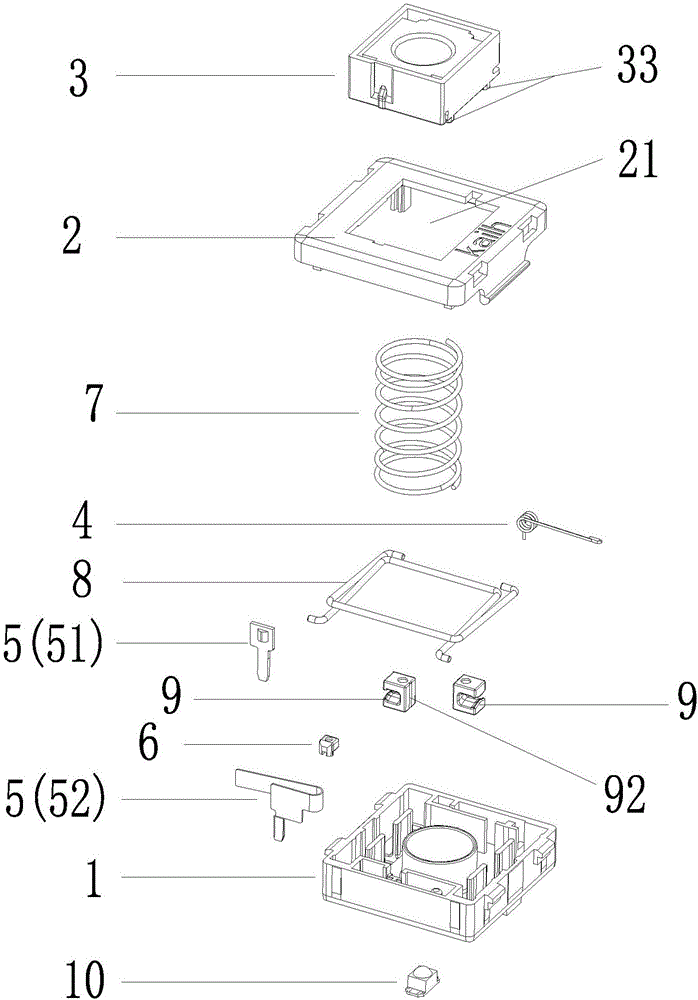

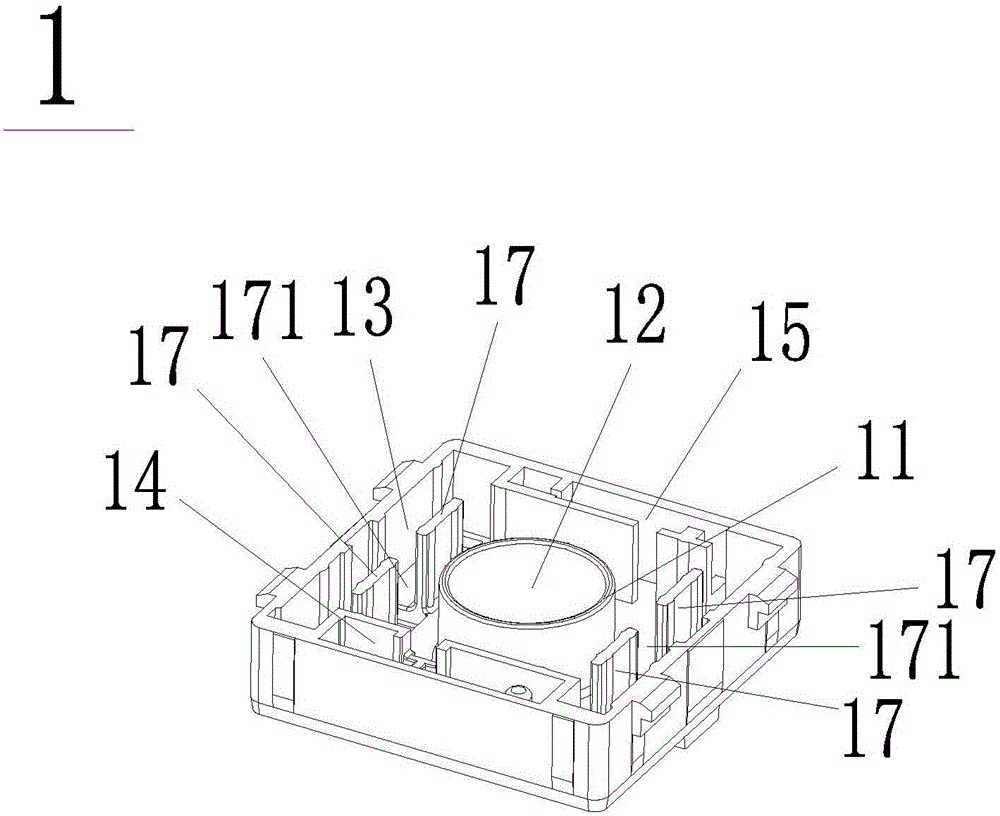

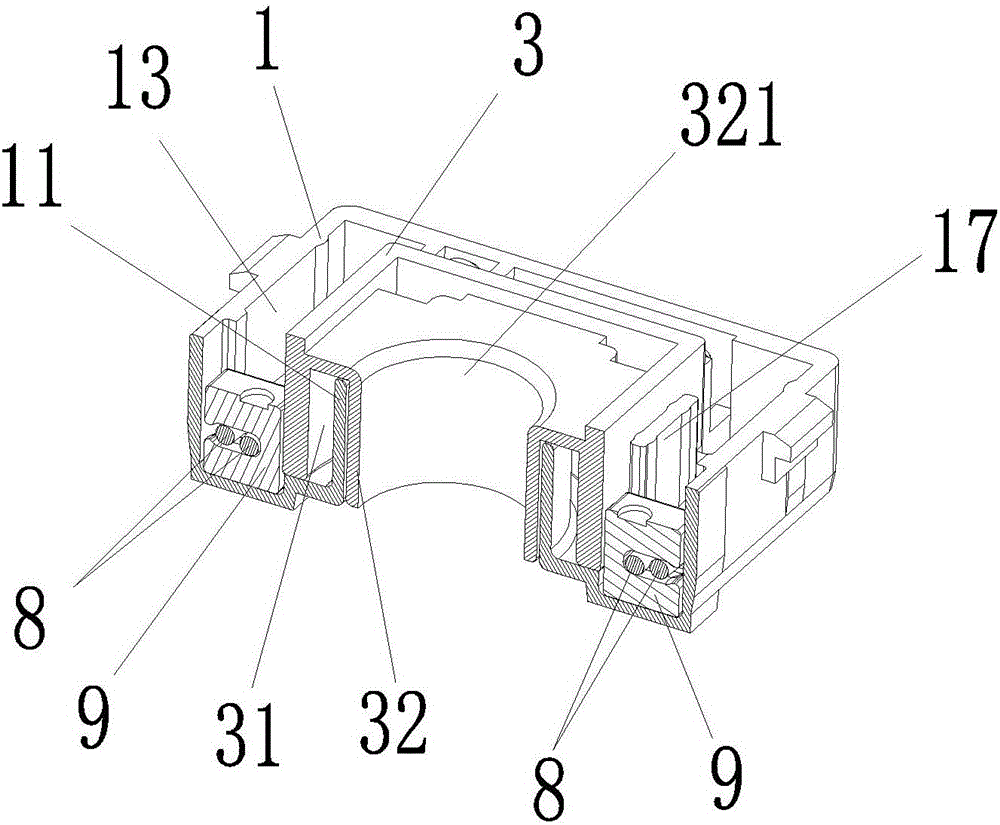

[0037] Please refer to Figure 1 to Figure 11 , the present embodiment provides a key switch with good balance, including a base 1 and a cover 2 covering the base 1, an opening 21 is opened on the cover 2, and the base 1 is also provided with The guide core 3, the torsion spring 4, the conduction assembly 5 and the guide core slider 6, wherein a guide post 11 protrudes upward at the center of the upper end of the base 1, and a guide post 11 is provided downward at the center of the guide post 11. Holes 12, one end of the base 1 is provided with a conduction assembly slot 14 for the insertion of the conduction assembly 5, and the other end is provided with a torsion spring slot 15 for the insertion of the torsion spring 4, on the upper end of the base 1 and located in the guide Two baffles 17 are respectively arranged on opposite sides of the column 11, and there is a gap 171 between the two baffles 17, so that the base 1 forms an annular accommodating groove around the baffle ...

Embodiment 2

[0044] Such as Figure 12 As shown, the main difference between this embodiment and Embodiment 1 is that the side of the positioning slider 9' in this embodiment is also provided with an arc-shaped limiter for the first balance bar 81 and the second balance bar 82 to snap into. The positioning slot 91', the limiting slot 91' has an opening 911', and the upper and lower parts of the opening 911' are respectively bent inward to form a protrusion 912'. However, the end surface of the protrusion 912 ′ in this embodiment is not provided with an angle, and the thickness of the positioning slider 9 ′ in this embodiment is thinner than that of the positioning slider 9 in the first embodiment.

Embodiment 3

[0046] Such as Figure 7 , Figure 10 , Figure 13 , Figure 14 and Figure 15 As shown, the main difference between the present embodiment and the first embodiment is that a groove is opened on the lower end surface of the guide core 3 , so that a plurality of guide core lobes 33 are formed on the lower end surface of the guide core 3 . At the same time, there are two ways to provide space for the guide core lobe 33, one of which is: on the base 1 and outside the guide post 11, there are several space for the guide core lobe 33 to extend into. groove 16, and the depth of the relief groove 16 is just equal to the height of the guide core lobe 33; another way is: on the base 1 and outside the guide post 11, there is a hole for the guide core lobe 33 to pass through A number of give way holes 16'.

[0047] In this embodiment, the number of the relief groove 16 and the relief hole 16' is the same as the number of guide core lobes 33. In this embodiment, the number of guide c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com