Protected cable terminal fastener

A cable termination and fastener technology, which is applied in the direction of connecting/terminating cable equipment, etc., can solve the problems of the cable itself, such as large elasticity, increased difficulty, bounce or slip, etc., to achieve good stability and save operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A protective cable terminal fastener of the present invention will be further described below in conjunction with the accompanying drawings:

[0016] It should be noted that the terms "upper", "lower", "front", "rear" and similar expressions used in this specification are only for the purpose of illustration, and are determined according to the actual situation in the embodiment.

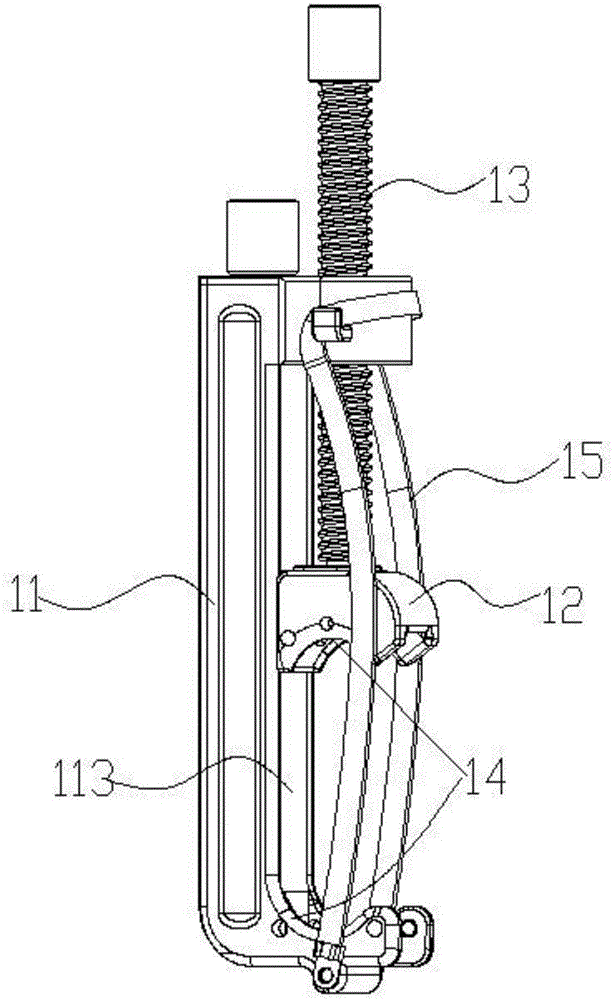

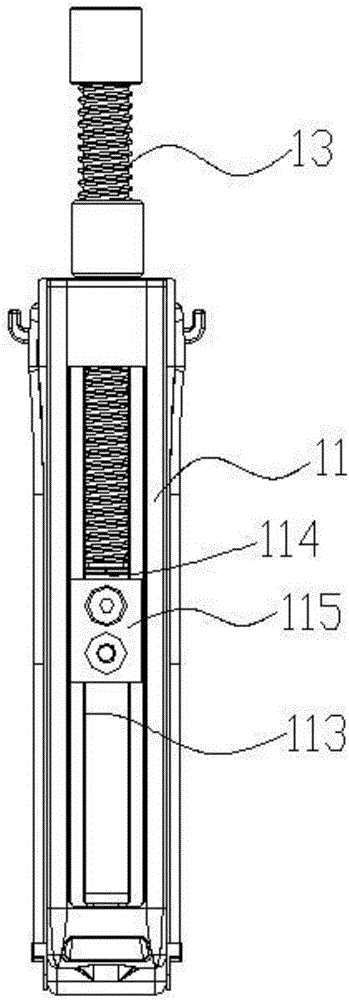

[0017] Such as Figure 1-2 As shown, a protective cable terminal fastener includes a crimping body 11, a dynamic pressure block 12, a crimping screw 13 and a protective belt 15. The top and bottom of the crimping body 11 are oppositely arranged, and the dynamic pressure block 12 is located Between the top and the bottom of the line body 11 and opposite to the bottom, the bottom of the line body 11 and the lower surface of the dynamic pressure block 12 are respectively provided with clamping structures 14 for clamping cables, and the compression screw 13 passes through vertically and is thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com