Dispensing mechanism with adjustable dispensing angle

A dispensing mechanism and point adjustment technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of damaging the chip assembly, falling on the chip, affecting the quality of dispensing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

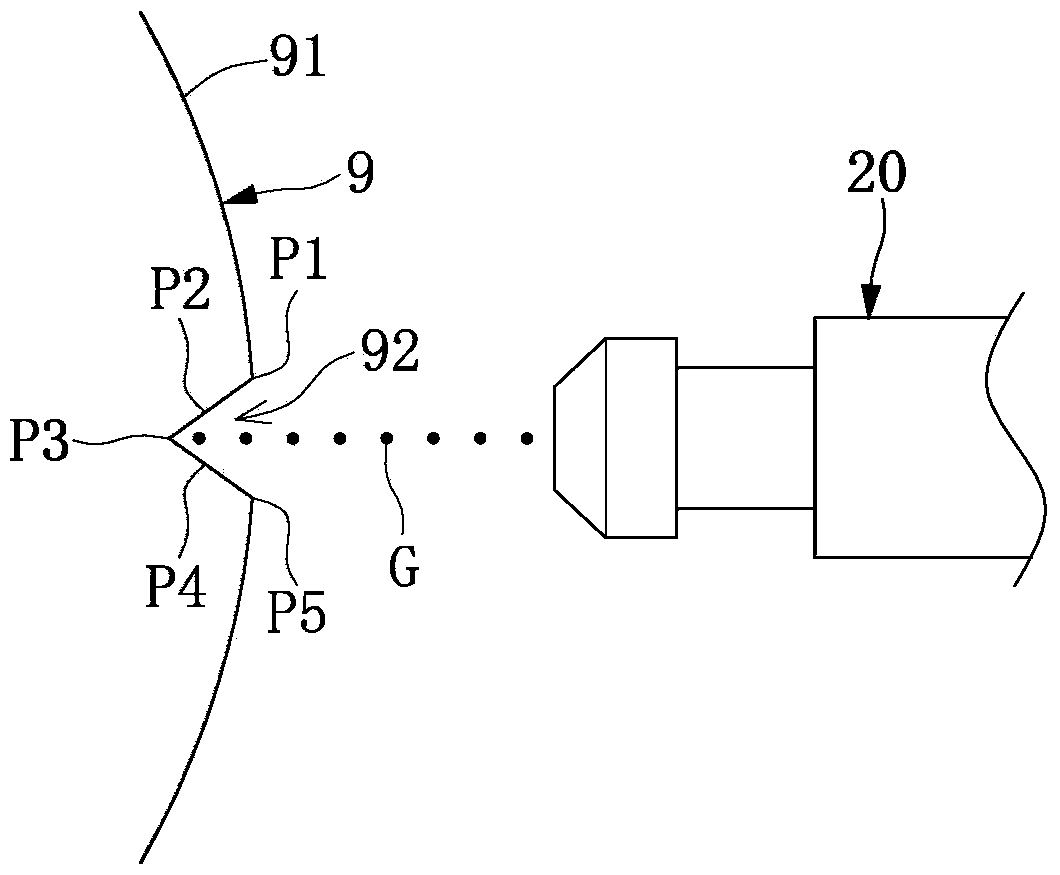

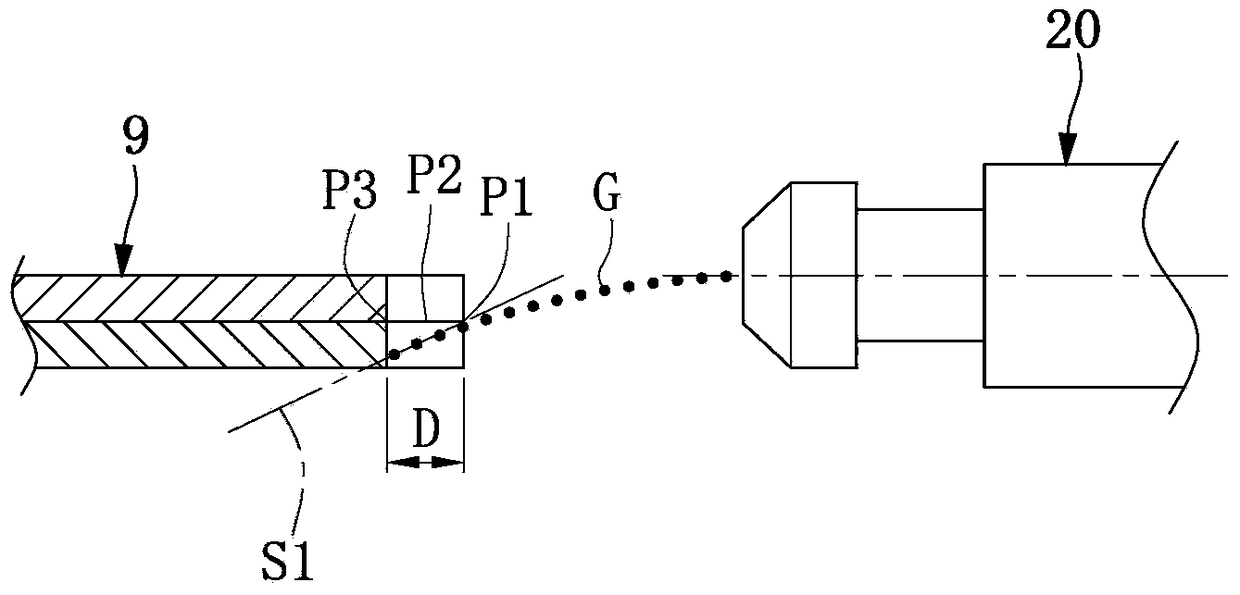

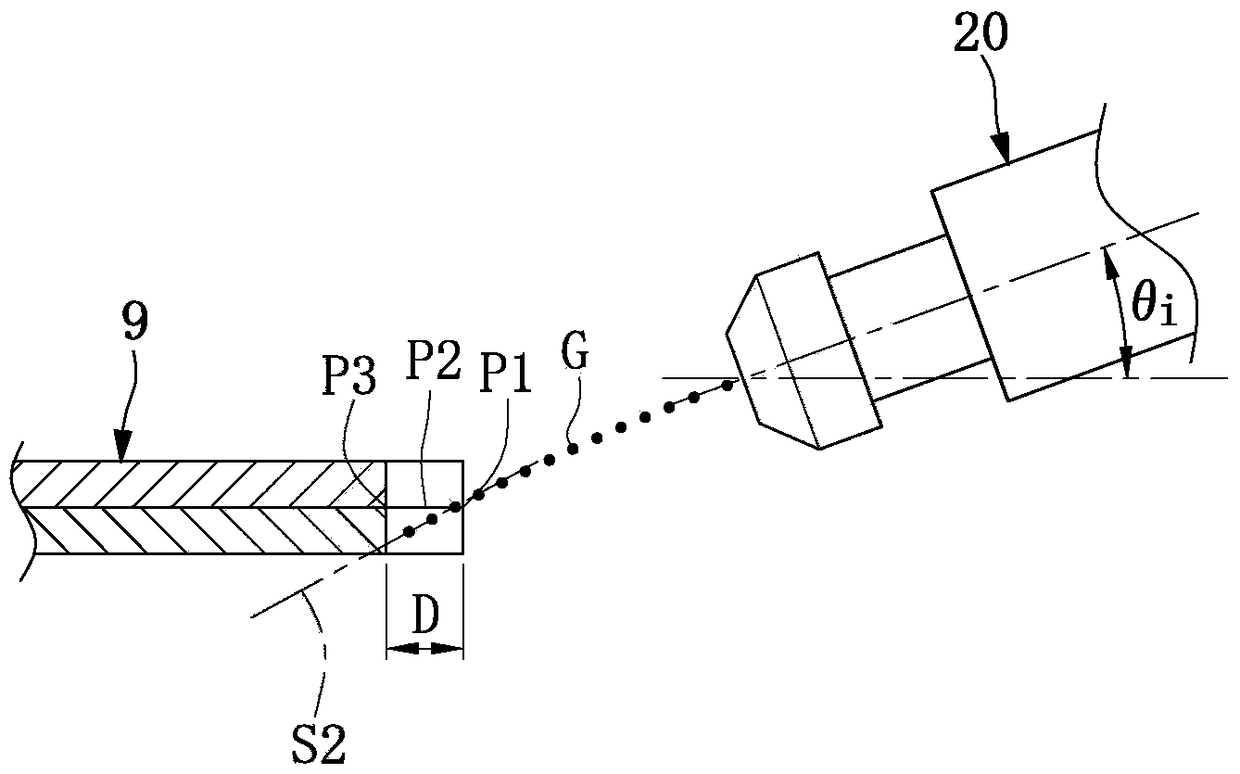

[0057] see figure 1 and figure 2 , the wafer assembly 9 is placed in a horizontal state and rotated, and the jetting head 20 injects glue droplets in the horizontal direction, and the to-be-glued part of the wafer assembly 9 includes a circumferential area 91 (including positions such as P1 and P5) and identification gaps Region 92 (contains P2, P3, P4, etc. positions). Here, the fan-shaped identifying notch area 92 is taken as an example, but the present invention is not limited thereto, for example, it can also be applied to identifying notch areas with other shapes. The glue droplet G ejected horizontally is originally accurately sprayed on the position P1 of the circumferential area 91. However, when the recognition notch area 92 of the wafer assembly 9 is rotated towards the jetting glue head 20, the path of the glue droplet G becomes a parabola due to gravity. The line may deviate from the position to be glued (such as the position of P2, P3, P4) in the identification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com