A method and device for adjusting and controlling electrofluidic printing by capacitive feedback

A capacitive feedback, electro-fluid technology, applied in printing devices, copying/marking methods, printing, etc., can solve the problems of uneven thickness of printed graphics, inability to guarantee the uniformity of printed ultra-fine patterns, and distortion of plane graphics. The effect of uniform printing pattern, reasonable inkjet volume and uniform graphics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

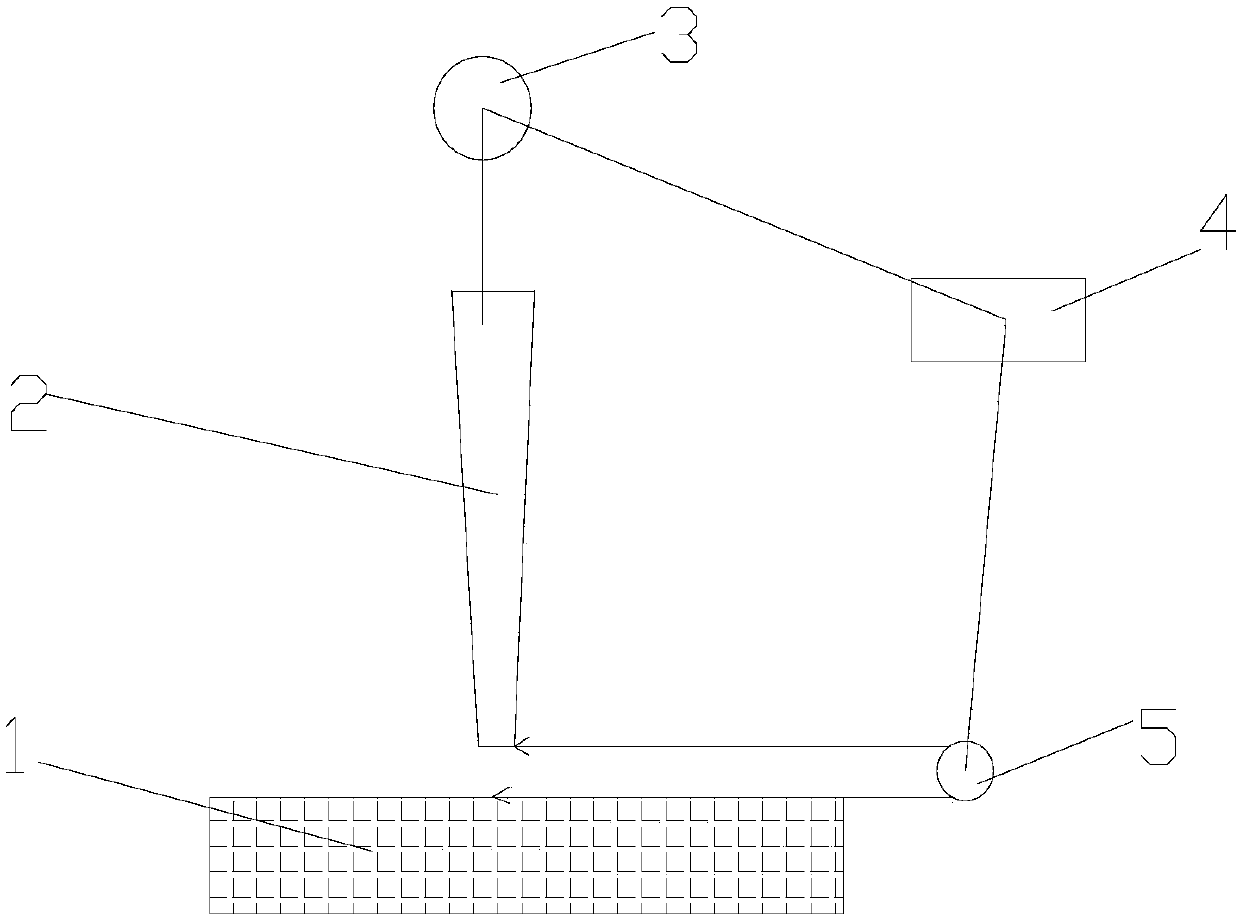

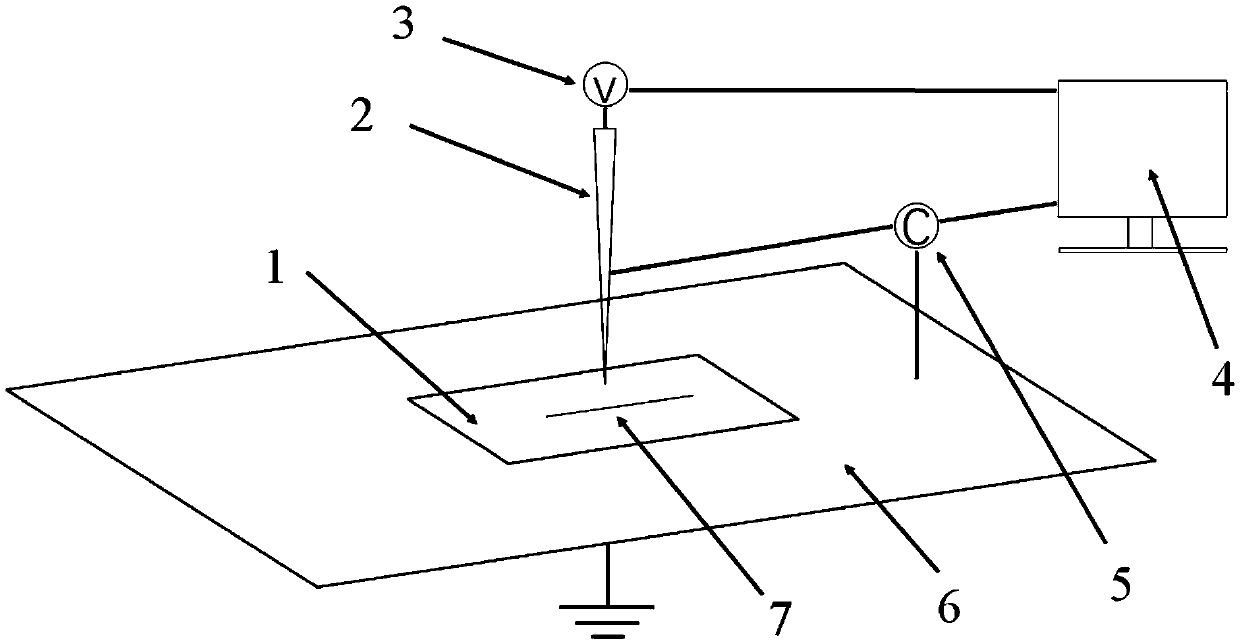

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] A method of regulating and controlling electrofluidic printing by capacitive feedback, comprising the steps of:

[0027] (1) Detect the capacitance between the nozzle of the ink-filled inkjet needle and the printing substrate through the capacitance detection module, and send the capacitance data to the data processing module;

[0028] (2) The data processing module processes the capacitance data sent by the capacitance detection module after receiving it, and sends the feedback data to the needle voltage output control module after processing;

[0029] (3) After receiving the feedback data sent by the data processing module, the needle voltage output control module adjusts the input voltage applied to the ink-filled inkjet needle.

[0030] In this embodiment, the capacitance detected by the capacitance detection module is the microcosmic ups and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com