Pulling-out tool used for annular oil seal

An oil seal and ring technology, which is applied in the field of pulling out tooling for ring oil seals, can solve the problems of increased worker workload, heavy labor, and low efficiency, and achieve the effects of compact overall structure, improved applicability, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

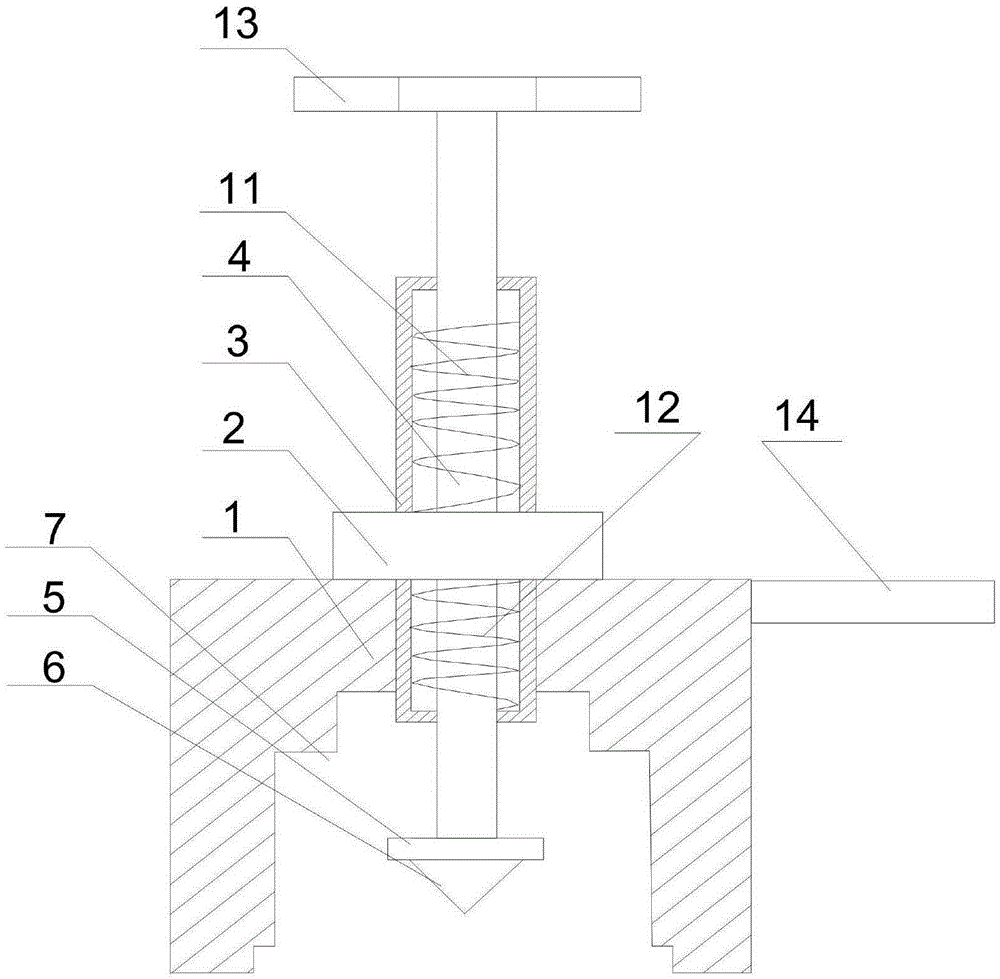

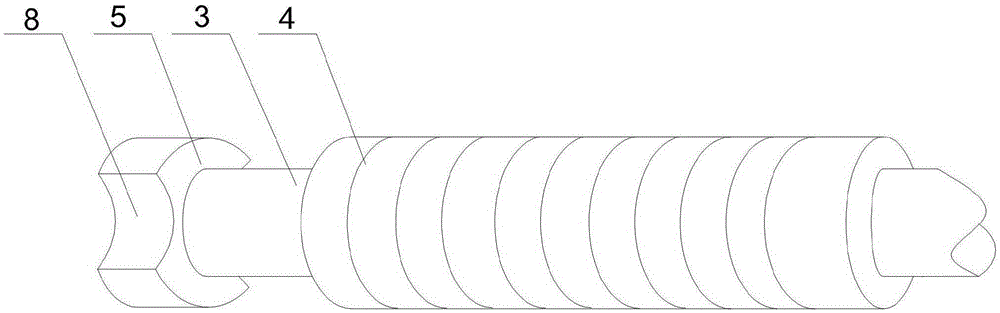

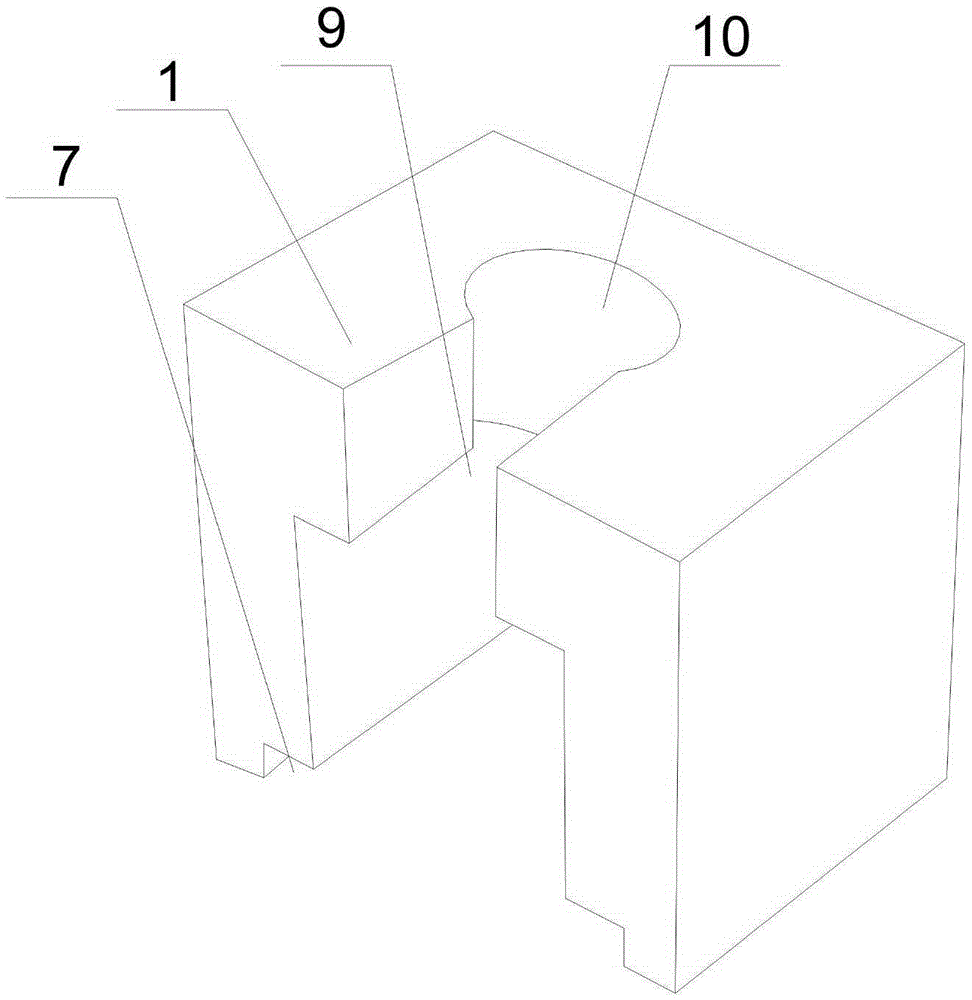

[0023] like Figure 1~Figure 3 As shown, this embodiment includes a support base 1 with a U-shaped groove at the bottom, a through hole 10 and an abdication hole 9 communicating with each other are opened at the upper end of the support base 1, and the extraction rod 4 passes through the through hole 10 and is placed in a U-shaped In the groove, a hollow and annular connecting cylinder 3 is set in the middle of the extracting rod 4, the connecting cylinder 3 is in contact with the inner wall of the through hole 10, and an external thread is also provided on the outer wall of the extracting rod 4, And the external thread is threadedly matched with the upper part of the inner wall of the connecting cylinder 3, and the end of the extraction rod 4 is rotated to be provided with a snap-in disc 5, the outer diameter of the snap-in disc 5 is larger than the outer diameter of the extraction rod 4; The nut 2, the screw nut 2 is threadedly matched with the connecting cylinder 3, the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com