Diaphragm and preparation method thereof, sound module and electronic device

A manufacturing method and sound technology, applied to electrical components, sensors, etc., can solve problems such as sound effect limitations, and achieve the effects of improving sound effects, simple manufacturing process, and high production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

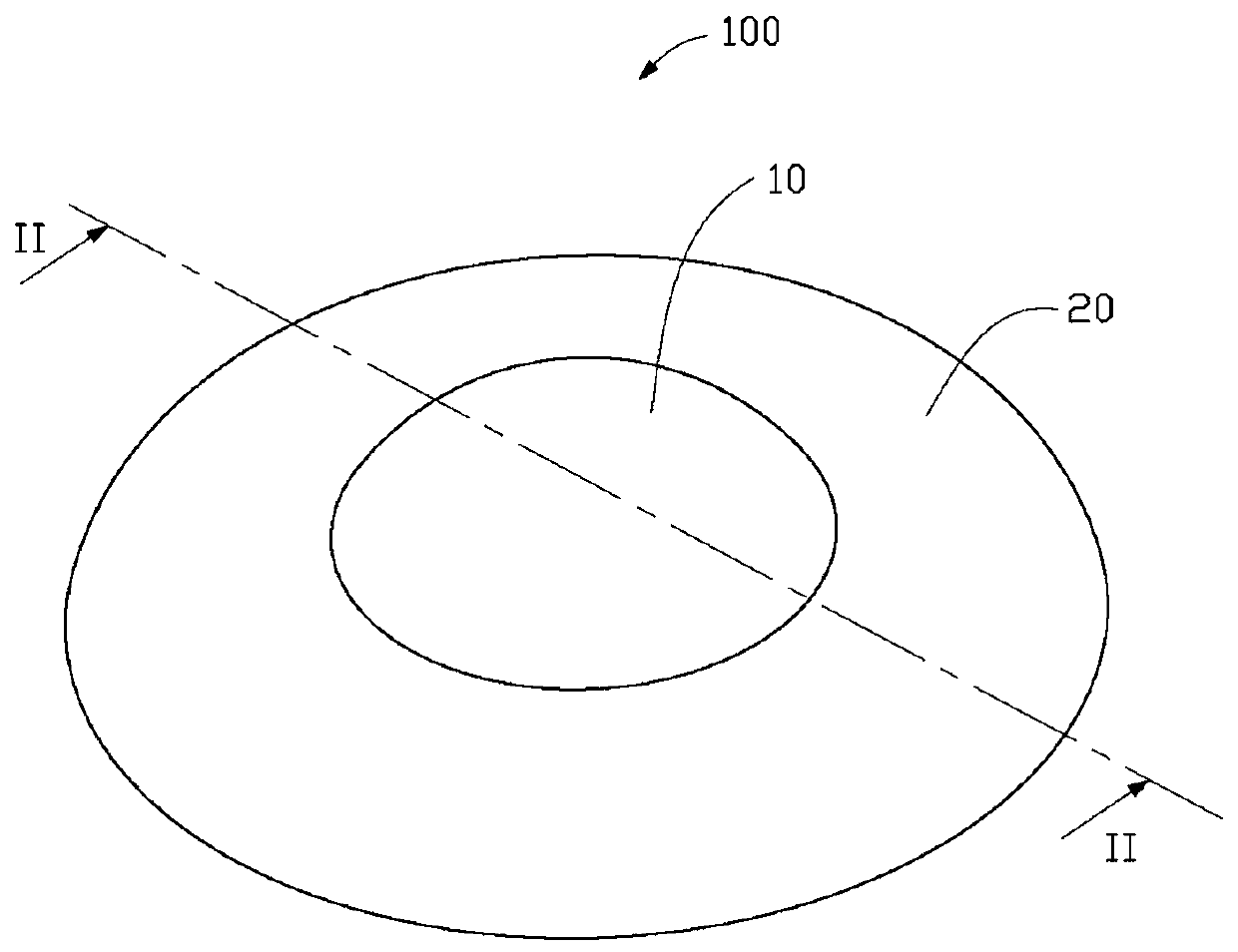

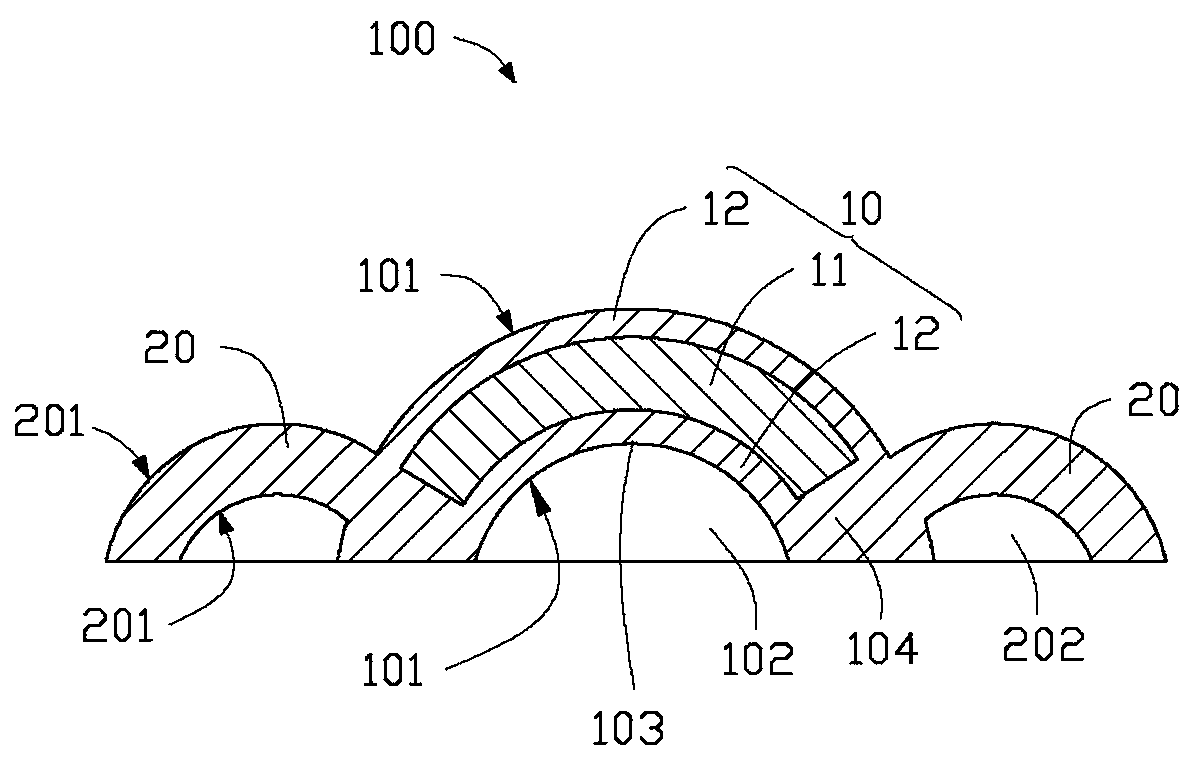

[0038] Please also refer to Figure 1~2 , the diaphragm 100 according to the preferred embodiment of the present invention is used in a sound module (not shown) of an electronic device (not shown). The electronic device can be an electronic device capable of producing sound, such as a computer, a mobile phone, an earphone, and an electronic reader. The diaphragm 100 includes a dome top 10 having a dome shape and a ring portion 20 extending from the outer periphery of the dome top 10 and surrounding the dome top 10 . The ball top 10 includes two resin layers 12 and a metal layer 11 sandwiched between the two resin layers 12 .

[0039] see figure 2 , the ball top 10 has two opposite first arcuate surfaces 101 , so that the ball top 10 forms a first arcuate groove 102 . The dome 10 has a central area 103 and a peripheral area 104 surrounding the central area 103 .

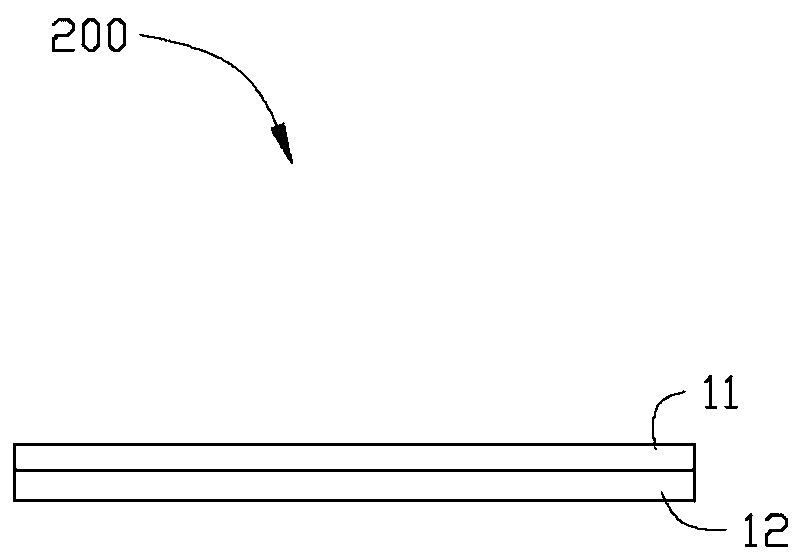

[0040] The size of the metal layer 11 is smaller than the size of each resin layer 12, so that the metal layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com