Multilateral UV curing machine

A curing machine, multilateral technology, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of low curing efficiency, uneven curing of substrate, etc., to ensure curing effect, curing effect is uniform, The effect of improving curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

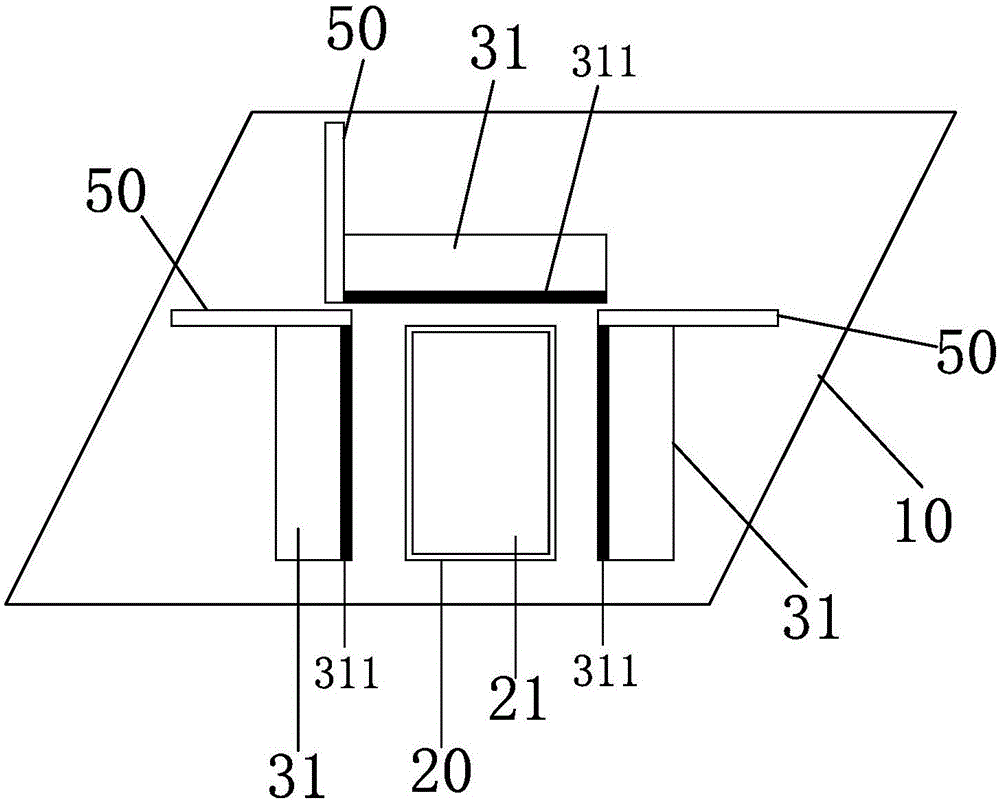

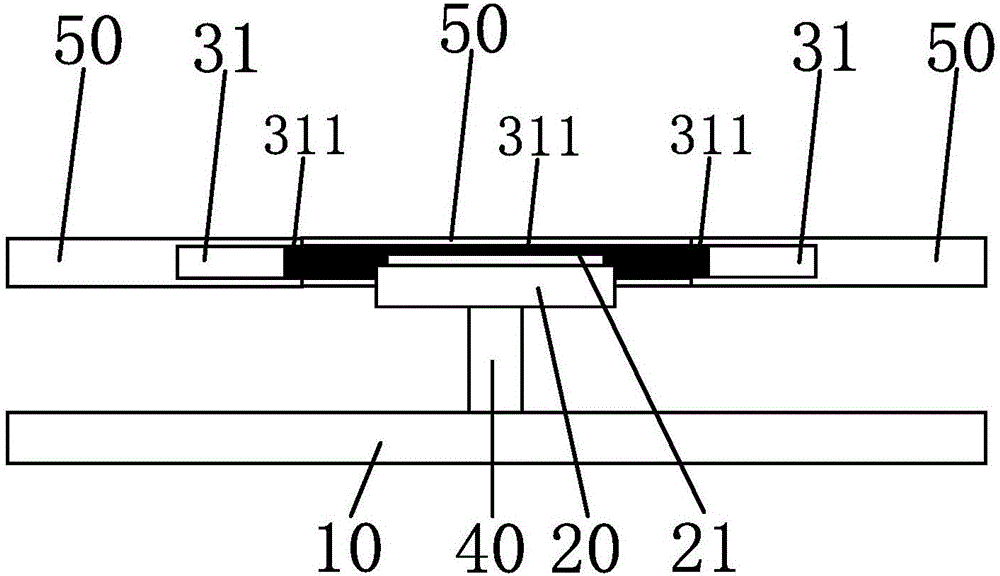

[0032] As another specific embodiment of the present invention, the polygonal UV curing machine further includes a sliding assembly that adjusts the horizontal displacement of the sides of each substrate 21 and the UV curing assembly; the sliding assembly includes a number of UV curing lamps 31 one by one. With matching guide rails, each UV curing lamp 31 slides along the corresponding guide rail toward or away from the corresponding side of the substrate 21. Through each slide rail 50, the relative displacement in the horizontal direction between the corresponding UV curing lamp 31 and the side of the substrate 21 can be individually adjusted to ensure that the horizontal curing distance of each side of the irregular substrate 21 is the same, and promote each The curing effect on the side is uniform.

[0033] As a preference of the above embodiment, the area of the irradiation side 311 of each UV curing lamp 31 is larger than the area of the side of the substrate 21 to ensur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap